Catalog excerpts

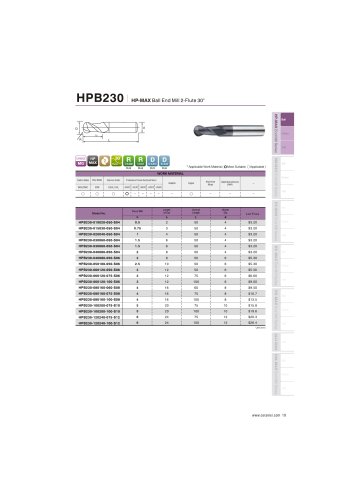

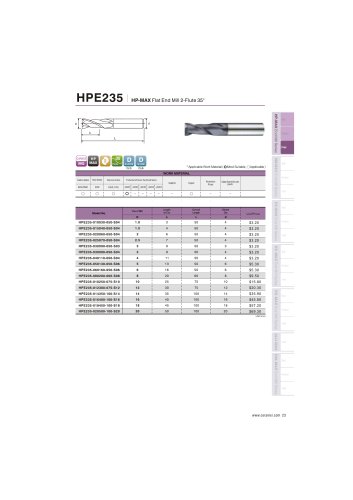

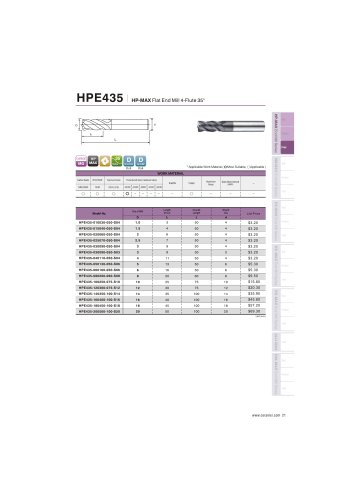

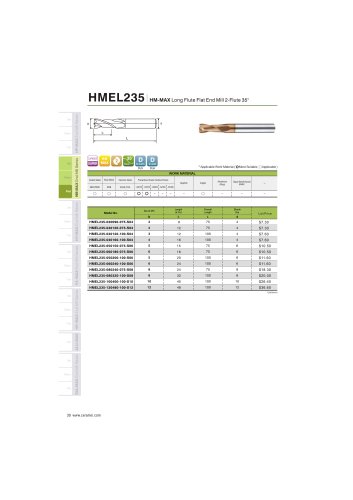

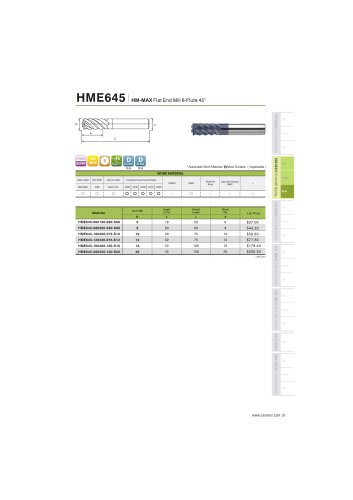

PROMOTIONALCARBIDE END MILLProducing Process HPB230 HP-MAX Ball End Mill 2-Flute 30° NO.l High quality bar selection CERAMEI cutter adopts European quality 0.2 mu, 0.4 mu of ultra-fine particle tungsten steel bars, high rigidity and strong resistance to strong guarantee for the service life of the cutter. NO.2 Advanced grinding equipment CERAMEI cutter adopts Germany WALTER and Australia's ACNA as the world's top universal tool grinding machine precision and grinding, ensure that every tool very good uniformity and stability. HPE435 HP-MAX Flat End Mill 4-Flute 35° NO.3 Full automation products manufacturing CERAMEI cutter adopts fully automatic manufacturing process strict and high standard, efficient and high quality production system, to further strengthen and improve the stability of cutting tool. HPE235 HP-MAX Flat End Mill 2-Flute 35° NO.4 Top coating technology CERAMEI cutter by Swiss PLATIT coating technology, excellent wear resistance and high efficient lubrication to ensure the service life of the cutter has extraordinary. NO.5 Strict quality inspection CERAMEI cutter adopts Germany ZOLLER 3D measuring instrument, achieves the product 100% detection, to ensure that each one tool factory precision 100% pass rate. DONGGUAN KOVES PRECISION TOOLS CO.,LTD No.33 Xing’er Road.Wusha District,Chang'an Town, Dongguan City,China KOVES Http ://www.ceramei.com

Open the catalog to page 1All Dongguan Koves Cutting Tool Co. catalogs and technical brochures

-

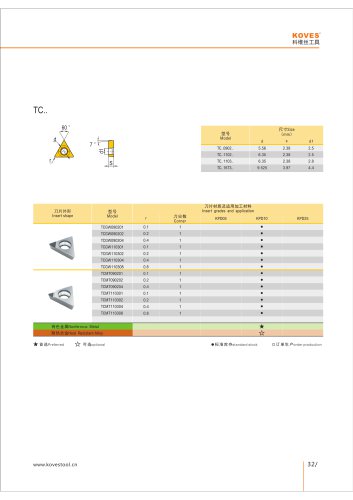

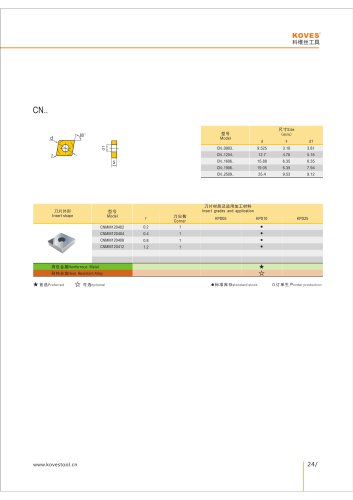

Carbide inserts 2018 catalog

112 Pages

-

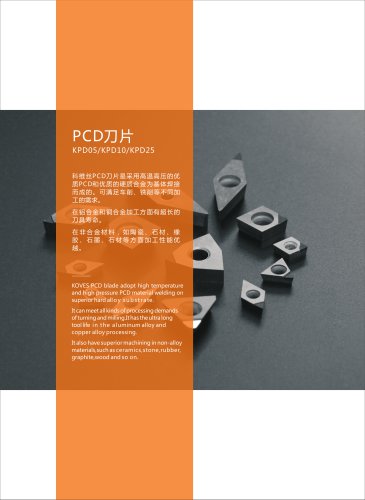

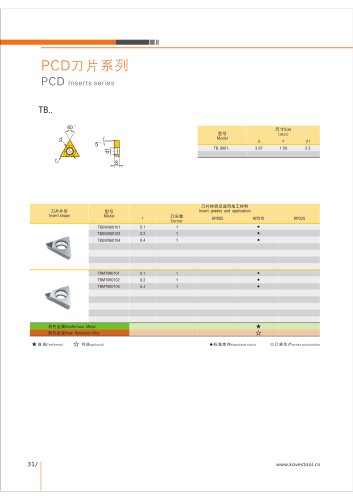

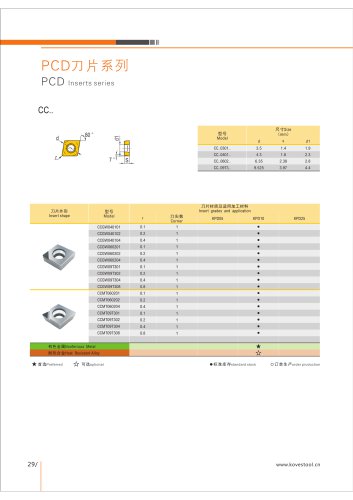

PCD diamond inserts and tools

25 Pages

-

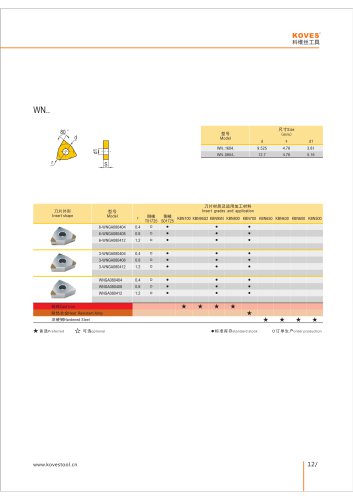

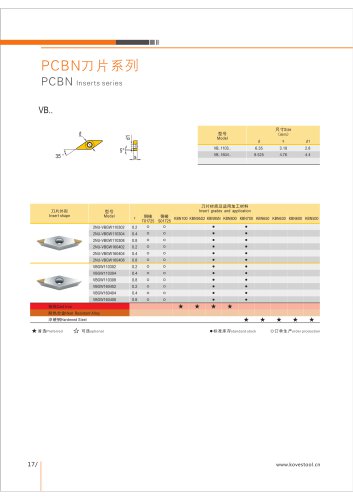

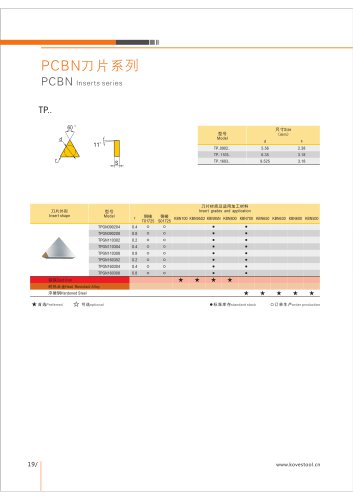

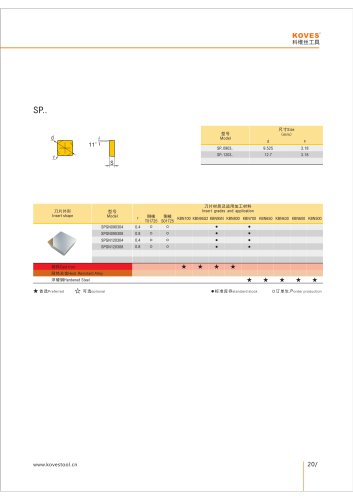

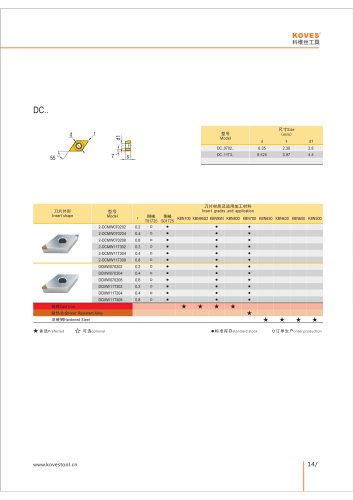

CBN inserts and tools

27 Pages

-

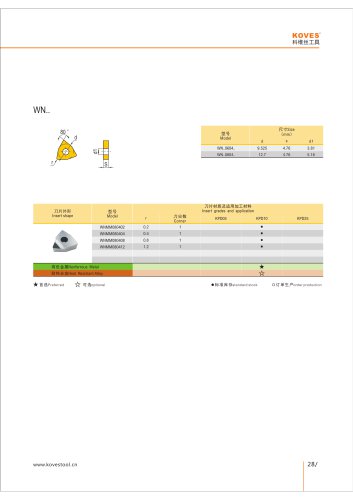

WNMM PCD DIAMOND INSERT

1 Pages

-

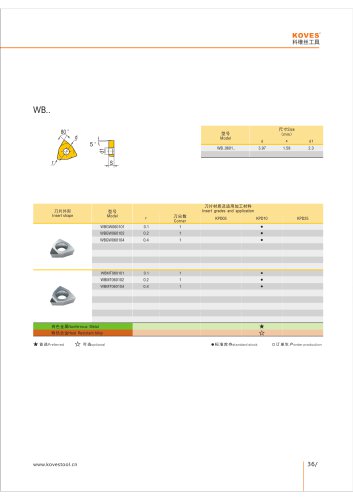

WBMT PCD DIAMOND INSERT

1 Pages

-

WBGW PCD DIAMOND INSERT

1 Pages

-

VNMM PCD DIAMOND INSERT

1 Pages

-

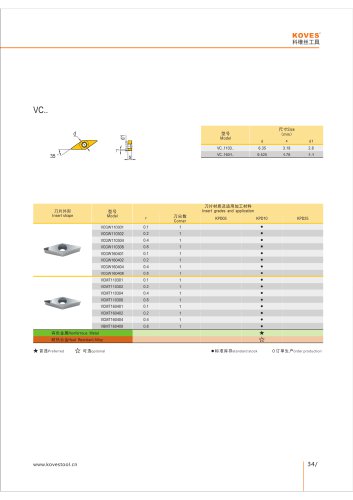

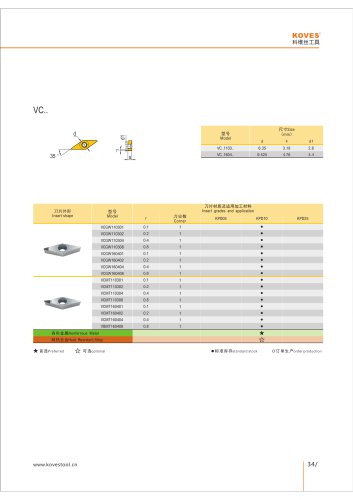

VCMT PCD DIAMOND INSERT

1 Pages

-

VCGW PCD DIAMOND INSERT

1 Pages

-

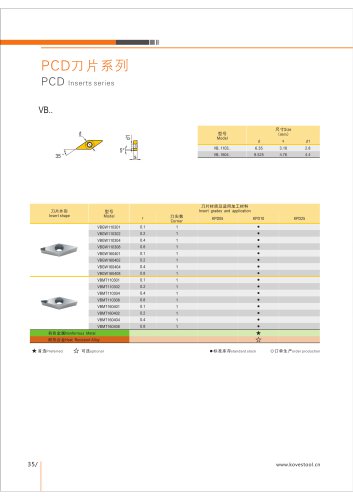

VBMT PCD DIAMOND INSERT

1 Pages

-

VBGW PCD DIAMOND INSERT

1 Pages

-

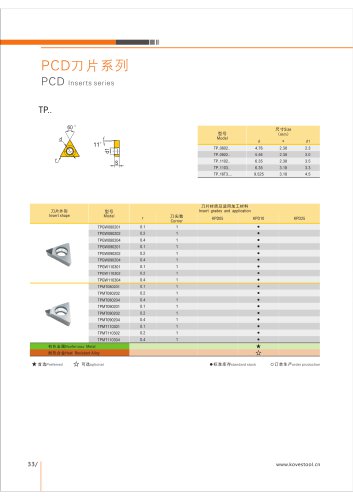

TPMT PCD DIAMOND INSERT

1 Pages

-

TPGW PCD DIAMOND INSERT

1 Pages

-

TPGN PCD DIAMOND INSERT

1 Pages

-

TNMM PCD DIAMOND INSERT

1 Pages

-

TCMT PCD DIAMOND INSERT

1 Pages

-

TCGW PCD DIAMOND INSERT

1 Pages

-

TBMT PCD DIAMOND INSERT

1 Pages

-

TBGW PCD DIAMOND INSERT

1 Pages

-

SPGN PCD DIAMOND INSERT

1 Pages

-

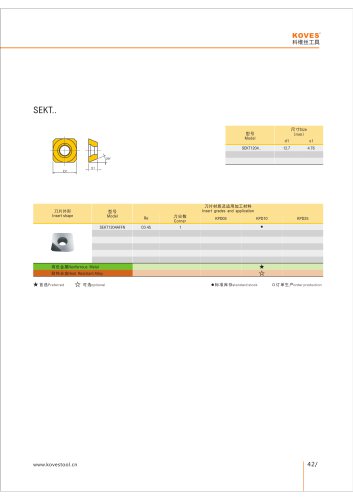

SEKT PCD DIAMOND INSERT

1 Pages

-

PSBR PCD DIAMOND INSERT

1 Pages

-

MGGN PCD DIAMOND INSERT

1 Pages

-

DNMM PCD DIAMOND INSERT

1 Pages

-

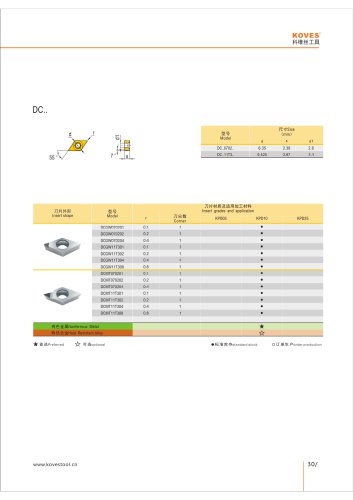

DCMT PCD DIAMOND INSERT

1 Pages

-

DCGW PCD DIAMOND INSERT

1 Pages

-

CNMM PCD DIAMOND INSERT

1 Pages

-

CCMT PCD DIAMOND INSERT

1 Pages

-

CCGW PCD DIAMOND INSERT

1 Pages

-

APMT PCD DIAMOND INSERT

1 Pages

-

WNGA PCBN DIAMOND INSERT

1 Pages

-

WBGW PCBN DIAMOND INSERT

1 Pages

-

VNGA PCBN DIAMOND INSERT

1 Pages

-

VCGW PCBN DIAMOND INSERT

1 Pages

-

VBGW PCBN DIAMOND INSERT

1 Pages

-

TPGW PCBN DIAMOND INSERT

1 Pages

-

TPGN PCBN DIAMOND INSERT

1 Pages

-

TNGA PCBN DIAMOND INSERT

1 Pages

-

SPGN PCBN DIAMOND INSERT

1 Pages

-

SNGA PCBN DIAMOND INSERT

1 Pages

-

PSBR PCBN DIAMOND INSERT

1 Pages

-

MGGN PCBN DIAMOND INSERT

1 Pages

-

DNGA PCBN DIAMOND INSERT

1 Pages

-

DCMW PCBN DIAMOND INSERT

1 Pages

-

CNGA PCBN DIAMOND INSERT

1 Pages

-

CCMW PCBN DIAMOND INSERT

1 Pages

-

PCD INSERT LIST

4 Pages