Catalog excerpts

Dongguan KIZI Precision Lapping Mechanical Manufacture Co.,Ltd — — Expert of Precision Lapping and Polishin

Open the catalog to page 1

Dongguan Ki zi Preci si on Lappi n g M e c h a n i c a l Manufacture Co. , Ltd is a national high- tech enterprise with private technology in Dongguan City, contract abiding and credit abiding in Guangdong Province, and a national high- tech enterprise. It mainly researches and develops, manufactures and sells CNC equipment such as high- precision surface grinding and polishing machine and its matching consumables. Our products are widely used in metal, non- metallic ( including ceramics, sapphire) and other parts grinding, polishing process, workpiece can obtain the best 1 um flatness and...

Open the catalog to page 3

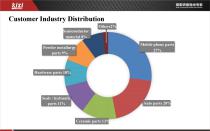

Mobile phone parts 27% Powder metallurgy parts 9% Seals / hydraulic parts 11%

Open the catalog to page 6

Product Introduction Single Side Lapping & Polishing Machine Double Side Lapping & Polishing Machine Double Side Fine Grinding Machine High Precision Thinning Machine Four Station Precision CMP Polishing Machine Grinding & Polishing Consumables

Open the catalog to page 7

Single Side Lapping & Polishing Machine It is mainly used for single side grinding and polishing of metal and nonmetal hard and brittle materials such as optical glass, crystal, quartz wafer, sapphire glass, lithium niobate, gallium arsenide, ceramics, ferrite, silicon wafer, valve plate, friction plate, rigid sealing ring, cylinder piston ring, oil pump blade, etc. Conditioning Ring ID(mm) Machine Weight(KG)

Open the catalog to page 8

Single Side Lapping & Polishing Machine It is mainly used for single side grinding and polishing of metal and nonmetal hard and brittle materials such as optical glass, crystal, quartz wafer, sapphire glass, lithium niobate, gallium arsenide, ceramics, ferrite, silicon wafer, valve plate, friction plate, rigid sealing ring, cylinder piston ring, oil pump blade, etc. Conditioning Ring ID(mm) Machine Weight(KG)

Open the catalog to page 9

Single Side Lapping & Polishing Machine This machine is designed for grinding or polishing one side of metallic and non-metallic materials and is particularly suitable for stainless steel, copper, aluminium alloys, hardware components, pneumatic and hydraulic some sealing elements, optical crystals, sapphire glass, LED sapphire substrates, LGP models, piezoelectric ceramics, alumina ceramics, plastic sheets and silicon wafers. Grinding Disc Diameter(mm) Maximum Processing Size(mm) Machine Weight(KG)

Open the catalog to page 10

Double Side Lapping & Polishing Machine Stainless steel, copper, aluminum alloy, hardware parts,air pressure, hydraulic pressure and other seals, optical crystal, sapphire glass, led sapphire substrate, light guide plate mold, piezoelectric ceramic chip, alumina ceramic, plastic sheet, silicon wafer and other metal and non- metallic materials, a large number of plane high precision grinding or polishing. KS25B Model Grinding Disc Diameter(m m) Fixtures Parameters Maximum Processing Diameter(mm) Machine Weight(kg)

Open the catalog to page 11

Double Side Lapping & Polishing Machine Stainless steel, copper, aluminum alloy, hardware parts,air pressure, hydraulic pressure and other seals, optical crystal, sapphire glass, led sapphire substrate, light guide plate mold, piezoelectric ceramic chip, alumina ceramic, plastic sheet, silicon wafer and other metal and non- metallic materials, a large number of plane high precision grinding or polishing. Model Size of Grinding Disc Rotational Speed(rpm) Rotational Speed(rpm) Rotational Speed(rpm) Center Wheel Large Gear Rings Star Wheel Lower Grinding Disc Center Wheel Upper Grinding Disc...

Open the catalog to page 12

Double Side Fine Grinding Machine Stainless steel, copper, aluminum alloy, hardware parts,air pressure, hydraulic pressure and other seals, optical crystal, sapphire glass, led sapphire substrate, light guide plate mold, piezoelectric ceramic chip, alumina ceramic, plastic sheet, silicon wafer and other metal and non- metallic materials, a large number of plane high precision grinding or polishing. KS700Y KS700Y Φ700*300*56 Φ700*300*56 Carrier Parameters Work Stations Machine Weight(KG) Model Lap Plate Diameter

Open the catalog to page 13

Automatic Double Side Grinding Machine This product is suitable for high precision and high efficiency machining of thin and disc-shaped parts of various shapes of metal and non-metal (hydraulic and pneumatic components, high precision shafts, seals, piston rings, carbide inserts, magnetic materials, etc.) on both upper and lower planes simultaneously. Workpiece Processing Size(mm) Distance between Grinding Discs(mm) Spindle Speed(r.p.m) Feeding Speed Grinding Disc Specifications(mm) Main Motor Power(kw) Machine Weight(kg)

Open the catalog to page 14

Vertical High Speed Thinning Machine This thinning machine is mainly used for high speed thinning of precision parts of non- metallic and metallic brittle and hard materials such as silicon wafer, ceramics, glass, quartz crystal, sapphire and other semiconductor. 1.The thickness of the workpiece can be reduced to 0 . 0 2mm without breaking. 2.The parallelism and flatness can be controlled within 0 . 0 0 2 mm. Model Diamond Grinding Wheel Sizes(mm) Maximum Processing Diameter(mm) Grinding Wheel Motor Power/SpeedKW/rpm) Workpiece Motor Power/Speed(KW/rpm) Pneumatic Pressure(MPa) Machine...

Open the catalog to page 15

Horizontal High Speed Thinning Machine It is suitable for the products with high hardness, thin thickness, high precision and high requirements. Such as: LED sapphire substrate, optical glass chip, quartz glass chip, silicon chip, ceramic chip, and other materials. 1.The thickness of the workpiece can be reduced to 0 . 0 2 mm without breaking. 2.The parallelism and flatness can be controlled within 0 . 0 0 2 mm. With high thinning efficiency, led sapphire substrate can be reduced by 48 um per minute and silicon wafer can be thinned by 2 5 0 um per minute. Model Diamond Grinding Wheel...

Open the catalog to page 16

Four Stations Precision CMP Polishing Machine It is mainly used in optical crystal, single crystal silicon wafer, silicon carbide chip, lithium niobate, lithium tantalate, germanium chip, sapphire glass, led sapphire substrate, piezoelectric ceramic chip, alumina ceramic and other semiconductor hard and brittle materials, a s well as large- scale plane high- precision CMP polishing. Model Grinding Disc Diameter(mm) Grinding Disc Speed(r.p.m) Main Motor Power(kw) Pneumatic Pressure(MPa) Machine Weight(kg)

Open the catalog to page 17Archived catalogs

-

KS700Y

9 Pages