Catalog excerpts

Particle Filter Element Prefilter element for the removal of solid contaminants in gases. Ultrapoly P Ultrapoly Particle Prefilter Element Type P Donaldson Ultrapoly P prefilter elements utilize a highly porous sintered polyethylene media for absolute filtration of particles down to 25 ìm in size. The primary filtration mechanism of this media is sieving, which captures most particles near the surface allowing for regeneration of the element and reduced operating cost through fewer element change-outs. Although the Ultrapoly P is primarily used as a particulate prefilter, a simple reversal of flow through the element allows the Ultrapoly P to be used as an effective course coalescing filter element, removing bulk quantities of water and oil from an air or gas stream (standard housings are equipped with an internal float drain, so no special equipment is required). Applications The Donaldson Ultrapoly P filter element is ideal in the following industries and applications: • Particulate prefilters upstream of final filters • Centralized prefiltration in compressor rooms • Particle filtration after cyclone separators • Coarse coalescing after cyclone separators and before fine coalescers AirCel™ ™ Operating Pressure psi Conversion Factor fp 15 0.25 30 0.36 45 0.50 60 0.60 75 0.75 90 0.90 100 1.00 115 1.10 130 1.20 150 1.40 160 1.50 175 1.60 190 1.75 200 1.90 220 2.00 250 2.10 Element Type Flow Rate 100 psi (cfm)* 0035 20 0070 41 0120 70 0210 123 0320 188 0450 264 0600 353 0750 441 1100 647 *cfm related to 15 psi abs. and 68°F Sizing example for pressure which deviates from nominal pressure: Vnom = 200 cfm, operating pressure = 130 psi Vcorr = Vnom/fp Vcorr = 200 cfm/1.25 = 165 cfm Calculated Size: Type 0320

Open the catalog to page 1

Ultrapoly P qÉä UMMKRQPKPSPQ=Erp^F qÉä UMMKPQPKPSPV=EïáíÜáå=jÉñáÅçF c~ñ TTMKQQUKPURQ ÅçãéêÉëëÉÇ~áê]ã~áäKÇçå~äÇëçåKÅçã ïïïKÇçå~äÇëçåKÅçã açå~äÇëçå=`çãé~åóI=fåÅK `çãéêÉëëÉÇ=^áê=C=d~ë mKlK=_çñ=NOVV jáååÉ~éçäáëI=jk RRQQMJNOVV=rKpK^K fåÑçêã~íáçå=áå=íÜáë=ÇçÅìãÉåí áë=ëìÄàÉÅí=íç=ÅÜ~åÖÉ=ïáíÜçìí=åçíáÅÉK «=OMMT=açå~äÇëçå=`çKI=fåÅK _ìääÉíáå=kçK=rcp_MNQR räíê~éçäó=m=NNJMT Particle retention rate related to 25 ìm P = 100% Oil retention rate according to ISO 12500-1 P = 90% Residual content at an inlet concentration of 10 mg/Nm3 P = 1 Filter Medium Pure, high molecular polyethylene Bonding Polyurethane...

Open the catalog to page 2All DONALDSON catalogs and technical brochures

-

UFK-L Aftercoolers

2 Pages

-

UFK-W Aftercoolers

3 Pages

-

P-EGS

3 Pages

-

CULINARY & PROCESS STEAM

8 Pages

-

Air Intake Systems

8 Pages

-

Clean DEF Solutions

4 Pages

-

Clean Fuel & Lubricant

32 Pages

-

Exhaust System Solutions

2 Pages

-

Pressure Control Systems

2 Pages

-

Innovative Fuel Systems

2 Pages

-

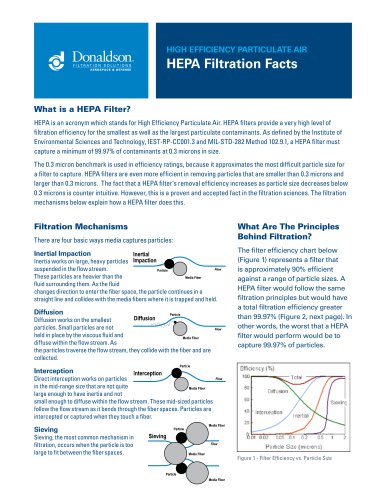

HEPA Filtration Facts

2 Pages

-

AEROSPACE & DEFENSE

4 Pages

-

pOWERCO RE® air cleaners

8 Pages

-

Donaldson Strata™ Tubes

4 Pages

-

PG-EG 0006 – 0192

6 Pages

-

(P)-GS N

6 Pages

-

Minerals Brochure

4 Pages

-

Metals Brochure

4 Pages

-

Industrial Filtration

10 Pages

-

Pharma Industry - Tetratex

2 Pages

-

Microfiltration

2 Pages

-

Power Generation

8 Pages

-

Vacuum Cleaner and Sweepers

4 Pages

-

Hydraulic Filtration

320 Pages

-

LDV FILTER KITS

4 Pages

-

Engine Liquid Filtration

154 Pages

-

Cabin Air Filtration

2 Pages

-

ToriT®powercore®dusT collecTors

16 Pages

-

PLEATED BAGS

3 Pages

-

DALAMATIC ® DUST COLLECTORS

12 Pages

-

HPK05

6 Pages

-

Engine Intake Systems

171 Pages

-

Ultrabev P-PF-BEV

4 Pages

-

Capsule Filters

8 Pages

-

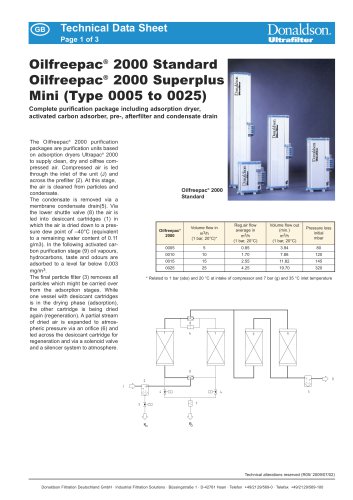

Oilfreepac® 2000 Standard

3 Pages

-

Clean Fuel Cart X011407

1 Pages

-

Clean Fuel Cart X011408

1 Pages

-

Leakage Detector DLD

2 Pages

-

SG Standard Filter Housing

7 Pages

-

Bulk Oil Cleaniness Levels

1 Pages

-

Clean Fuel Cart X011431

1 Pages

-

Venting Product Overview

2 Pages

-

Vacuum Cleaners and Sweepers

4 Pages

-

Chemicals Brochure

4 Pages

-

DPF Thermal Regenerator IOM

16 Pages

-

Adsorbent Breather Assembly

2 Pages

-

Adsorbent Pouch Filter

2 Pages

-

Adsorbent Breather Filter

2 Pages

-

Bulk hP

4 Pages

-

ULTRAPOREX SB

2 Pages

-

LITHOGUARD®

2 Pages

-

BSMmax

2 Pages

-

Valves & Solenoids

2 Pages

-

DT filter

22 Pages

-

Off-Line Filtration

14 Pages

-

Sight Glasses

1 Pages

-

Strainers

4 Pages

-

Valves

6 Pages

-

Breathers

14 Pages

-

TT15/30/60

2 Pages

-

SP100/120

4 Pages

-

Low Pressure Filters

64 Pages

-

WL16

4 Pages

-

Medium Pressure Filters

38 Pages

-

W613

4 Pages

-

FPK02

6 Pages

-

HPK02

4 Pages

-

High Pressure Filters

86 Pages

-

panel filter

1 Pages

-

GDX

4 Pages

-

DISK DRIVE SEALS

2 Pages

-

ADSORBENT LABEL FILTER (ALF)

2 Pages

-

Hydraulic Filtration

374 Pages

-

Engine Liquid Filtration

132 Pages

-

Oil/Water Separators

6 Pages

-

SYNTEQ XP M/S

2 Pages

-

Synteq XP

4 Pages

-

Ultrac? AK

2 Pages

-

Ultrapoly? PE

2 Pages

-

ULTRAC A

2 Pages

-

Dryer Package Filters

2 Pages

-

SG Compressed Air Filters

2 Pages

-

AG Compressed Air Filters

2 Pages

-

Rotary Valves

10 Pages

-

Unimaster® Dust Collector

4 Pages

-

Unicell Dust Collectors

6 Pages

-

Downflo Dust Collectors

6 Pages

Archived catalogs

-

Sensor Vents

2 Pages

-

Fluid Analysis

12 Pages

-

Exhaust Product

186 Pages