Catalog excerpts

Ultra-Filter™ Compressed Air Filters – DF series Compressed Air & Process Filtration

Open the catalog to page 1

Think Purity. Think Donaldson. Ultra-Filter DF Series Superplus Version As one of the world’s leading manufacturers of compressed air purification equipment and process filters, and with over 35 years of expertise, Donaldson has built a comprehensive engineering, manufacturing, and customer support network providing filters that meet the most demanding application requirements. Donaldson's innovative designs focus on energy-efficient operation and reliable performance to minimize operating expenses and reduce downtime. Donaldson provides industrial air, sterile air, culinary steam, tank...

Open the catalog to page 2

1 Ultra-Filter™ design & efficiency The New Design — Innovative to the Core Flow Optimized Airflow Unrivaled Eficiency The economic efficiency is clearly indicated by the reduction in differential pressure. A 3.0 PSI lower differential pressure over 8000 operating hours at 600 scfm saves $1,452 per year (based on 100 psig operating pressure, 120 kW installed power and $0.08/kWh.) This practical example shows that the investment in optimizing the compressed air system rapidly pays for itself. Unrivaled high performance. Donaldson Ultra-Filter was developed on the basis of worldwide...

Open the catalog to page 3

2 Ultra-Filter™ energy savings & ease of use unrivaled Energy Savings Further energy savings are achieved by the timely replacement of used filter elements. The most economic time for filter changeout is determined by the Economizer that continuously measures the differential pressure. An integrated microprocessor evaluates the measurement data and compares the higher energy costs caused by pressure loss with the costs of a new filter element. The most cost-effective element replacement time is calculated and LEDs then signal that filter changeout is necessary. Unrivaled Ease of Use The new...

Open the catalog to page 4

3 Ultra-Filter™ flexibility & safety Unrivaled Flexibility All filters can be used either as coalescing filters (flow through the element from the inside to the outside) or as particulate filters (outside to inside flow). If the requirements change, the filter head does not need to be rotated. Changing the coding clip inside the filter bowl allows the filter element to be rotated and changes the flow direction. The coalescing filter becomes a particulate filter in seconds – and vice versa. Optional wall supports are available on request for flexible wall mounting. The telescopic design of...

Open the catalog to page 5

4 Ultra-Filter™ specifications Model Capacity1 (scfm) Connection (inches FNPT) Element Dimensions (inches) Standard2 Weight (lbs) Superplus2 Weight (lbs) Standard Superplus Size Qty. Height Width Height Width DF 0035 20 1/4 0035 1 7.5 3.5 16 3.5 1 3 DF 0070 41 3/8 0070 1 11.5 4.5 18 4.5 2 4 DF 0120 70 1/2 0120 1 13.5 4.5 20 4.5 2 4 DF 0210 123 3/4 0210 1 14.5 6 21 6 5 6 DF 0320 188 1 0320 1 17.5 6 24 6 5 7 DF 0450 264 1-1/4 0450 1 23 7.5 29 7.5 12 7 DF 0600 353 1-1/2 0600 1 23 7.5 31 7.5 12 7 DF 0750 441 2 0750 1 23 7.5 31 7.5 12 7 DF 1100 647 2 1100 1 30 7.5 35 7.5 16 15 Dimensions &...

Open the catalog to page 6

5 Ultra-Filter™ sizing/selection guidelines Capacity Correction Factors The published standard capacities for compressed air Ultra-Filter DF Series filters are based on 100 psig inlet pressure and 100°F inlet temperature. When these conditions vary, a given Ultra-Filter DF Series filter will be able to purify either more or less compressed air than its standard capacity. There are two ways in which this information can be used. The first is to start with a specific Capacity correction factors for differing system air pressure (C1) System Pressure (psig) 15 30 45 60 75 90 100 115 130 150 160...

Open the catalog to page 7

Donaldson Company, Inc. Compressed Air and Process Filtration PO Box 1299 Minneapolis, MN 55440-1299 U.S.A. Tel 800-543-3634 (USA) Tel 800-343-3639 (within Mexico) Fax 952-885-4791 compressedair@donaldson.com donaldson.com Ultra-Filter Compressed Air Filters – DF Series Brochure (10/10) © 2007 Printed in the U.S.A. on recycled paper. Information in this document is subject to change without notice. • Over 1,000 engineers and scientists worldwide • Over 1,500 issued, active and pending patents • Proprietary media for durability and performance • Energy saving, reliable filters and dryers •...

Open the catalog to page 8All DONALDSON catalogs and technical brochures

-

UFK-L Aftercoolers

2 Pages

-

UFK-W Aftercoolers

3 Pages

-

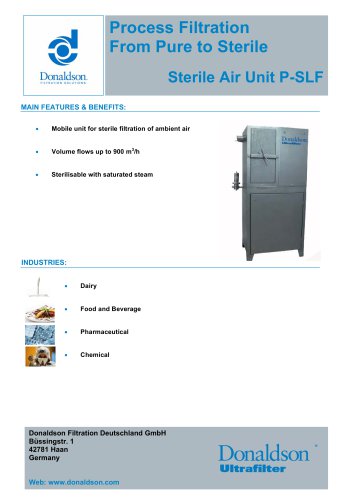

P-EGS

3 Pages

-

CULINARY & PROCESS STEAM

8 Pages

-

Air Intake Systems

8 Pages

-

Clean DEF Solutions

4 Pages

-

Clean Fuel & Lubricant

32 Pages

-

Exhaust System Solutions

2 Pages

-

Pressure Control Systems

2 Pages

-

Innovative Fuel Systems

2 Pages

-

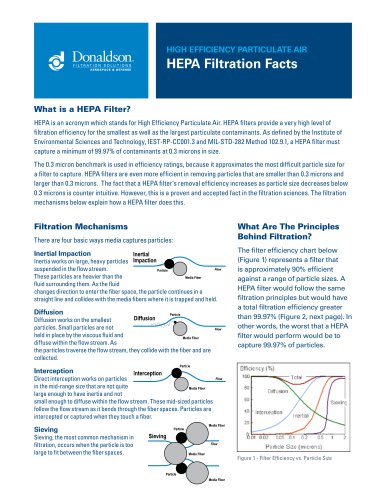

HEPA Filtration Facts

2 Pages

-

AEROSPACE & DEFENSE

4 Pages

-

pOWERCO RE® air cleaners

8 Pages

-

Donaldson Strata™ Tubes

4 Pages

-

PG-EG 0006 – 0192

6 Pages

-

(P)-GS N

6 Pages

-

Minerals Brochure

4 Pages

-

Metals Brochure

4 Pages

-

Industrial Filtration

10 Pages

-

Pharma Industry - Tetratex

2 Pages

-

Microfiltration

2 Pages

-

Power Generation

8 Pages

-

Vacuum Cleaner and Sweepers

4 Pages

-

Hydraulic Filtration

320 Pages

-

LDV FILTER KITS

4 Pages

-

Engine Liquid Filtration

154 Pages

-

Cabin Air Filtration

2 Pages

-

ToriT®powercore®dusT collecTors

16 Pages

-

PLEATED BAGS

3 Pages

-

DALAMATIC ® DUST COLLECTORS

12 Pages

-

HPK05

6 Pages

-

Engine Intake Systems

171 Pages

-

Ultrabev P-PF-BEV

4 Pages

-

Capsule Filters

8 Pages

-

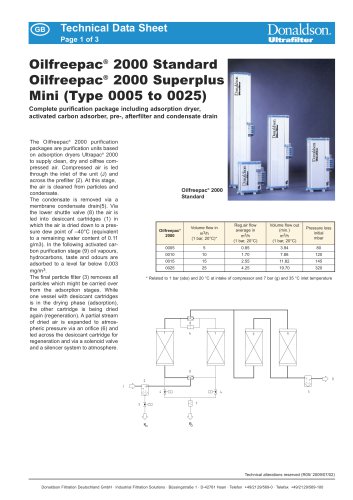

Oilfreepac® 2000 Standard

3 Pages

-

Clean Fuel Cart X011407

1 Pages

-

Clean Fuel Cart X011408

1 Pages

-

Leakage Detector DLD

2 Pages

-

SG Standard Filter Housing

7 Pages

-

Bulk Oil Cleaniness Levels

1 Pages

-

Clean Fuel Cart X011431

1 Pages

-

Venting Product Overview

2 Pages

-

Vacuum Cleaners and Sweepers

4 Pages

-

Chemicals Brochure

4 Pages

-

DPF Thermal Regenerator IOM

16 Pages

-

Adsorbent Breather Assembly

2 Pages

-

Adsorbent Pouch Filter

2 Pages

-

Adsorbent Breather Filter

2 Pages

-

Bulk hP

4 Pages

-

ULTRAPOREX SB

2 Pages

-

LITHOGUARD®

2 Pages

-

BSMmax

2 Pages

-

Valves & Solenoids

2 Pages

-

DT filter

22 Pages

-

Off-Line Filtration

14 Pages

-

Sight Glasses

1 Pages

-

Strainers

4 Pages

-

Valves

6 Pages

-

Breathers

14 Pages

-

TT15/30/60

2 Pages

-

SP100/120

4 Pages

-

Low Pressure Filters

64 Pages

-

WL16

4 Pages

-

Medium Pressure Filters

38 Pages

-

W613

4 Pages

-

FPK02

6 Pages

-

HPK02

4 Pages

-

High Pressure Filters

86 Pages

-

panel filter

1 Pages

-

GDX

4 Pages

-

DISK DRIVE SEALS

2 Pages

-

ADSORBENT LABEL FILTER (ALF)

2 Pages

-

Hydraulic Filtration

374 Pages

-

Engine Liquid Filtration

132 Pages

-

Oil/Water Separators

6 Pages

-

SYNTEQ XP M/S

2 Pages

-

Synteq XP

4 Pages

-

Ultrac? AK

2 Pages

-

Ultrapoly? PE

2 Pages

-

ULTRAC A

2 Pages

-

Dryer Package Filters

2 Pages

-

SG Compressed Air Filters

2 Pages

-

AG Compressed Air Filters

2 Pages

-

Rotary Valves

10 Pages

-

Unimaster® Dust Collector

4 Pages

-

Unicell Dust Collectors

6 Pages

-

Downflo Dust Collectors

6 Pages

Archived catalogs

-

Sensor Vents

2 Pages

-

Fluid Analysis

12 Pages

-

Exhaust Product

186 Pages