Catalog excerpts

Process Filtration From Pure to Sterile(P)-GS N MAIN FEATURES & BENEFITS: • High dirt holding capacity at low differential pressure and high flow rate • Regenerable by Back-flushing or ultrasonication • Excellent material resistance towards Steam and aggressive media • Down to 0,01 ^m in saturated steam • Welded version approved for Food Contact Use acc. to CFR Title 21 & 1935/2004/EC INDUSTRIES: Dairy Food & Beverage Industry Fermentation Pharmaceutical Industry Chemical Industry Donaldson Filtration Deutschland GmbH Bussingstr. 1 42781 Haan Germany

Open the catalog to page 1

(P)-GS N PRODUCT DESCRIPTION The (P)-GS N filter consists of a regenerable pleated stainless steel filter matrix in a stainless steel cartridge. The retention rate extends from 1 pm to 25 pm. Typical applications for (P)-GS N filter elements include: The (P)-GS N filter retains contaminants, such as particles, abrasion of valves and sealings as well as rust. An improved steam quality ensures longer service life of the filters to be sterilized and increases the efficiency of the entire process. The (P)-GS N filter element offers the possibility of a particularly economic filtration, since...

Open the catalog to page 2

(P)-GS N PRODUCT SPECIFICATIONS Product Specification Temperature Range Maximum Differential Pressure (Flow Direction: Outside to Inside) Donaldson Ultrafilter - 3 -PRODUCT SPECIFICATIONS & RETENTION RATES

Open the catalog to page 3

Process Filtration (P)-GS N MATERIAL COMPLIANCE USA All components of the (P)-GS N filter element are FDA listed for food contact use in the Code of Federal Regulations (CFR), Title 21. For applications without requirement of FDA approval, a cost-effective version with plastic steel potting is available. Filter Materials Filter Matrix: Support: End Caps: O-Rings: Alternatively: All products have been inspected and released by Quality Assurance as having met the following requirements: All fi lters are fabricated without the use of binders, adhesives, additives or surface-active agents. All...

Open the catalog to page 4

Process Filtration FLOW CHARACTERISTICS Initial Diff. Pressure [mbar] Initial Diff. Pressure [mbar] FLOW CHARACTERISTICS

Open the catalog to page 5

(P)-GS N AVAILABLE END CAP CONFIGURATIONS Dimensions (CODE 7 connection): CODE 7: 2 x 226 o-rings, bayonet 2 locking tabs, Dimensions (uf plug connection): * Plug-type connection with double o-ring ** Correction factor Filtration surface & Flow rate Technical alterations reserved 04/2009 For information on integrity test equipment or integrity test services, please contact your Donaldson Sales Engineer and visit our website at www.donaldson.com!

Open the catalog to page 6All DONALDSON catalogs and technical brochures

-

UFK-L Aftercoolers

2 Pages

-

UFK-W Aftercoolers

3 Pages

-

P-EGS

3 Pages

-

CULINARY & PROCESS STEAM

8 Pages

-

Air Intake Systems

8 Pages

-

Clean DEF Solutions

4 Pages

-

Clean Fuel & Lubricant

32 Pages

-

Exhaust System Solutions

2 Pages

-

Pressure Control Systems

2 Pages

-

Innovative Fuel Systems

2 Pages

-

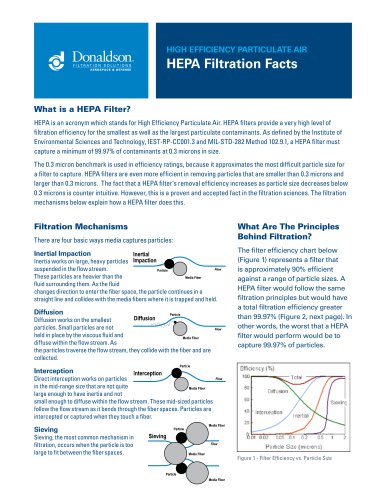

HEPA Filtration Facts

2 Pages

-

AEROSPACE & DEFENSE

4 Pages

-

pOWERCO RE® air cleaners

8 Pages

-

Donaldson Strata™ Tubes

4 Pages

-

PG-EG 0006 – 0192

6 Pages

-

Minerals Brochure

4 Pages

-

Metals Brochure

4 Pages

-

Industrial Filtration

10 Pages

-

Pharma Industry - Tetratex

2 Pages

-

Microfiltration

2 Pages

-

Power Generation

8 Pages

-

Vacuum Cleaner and Sweepers

4 Pages

-

Hydraulic Filtration

320 Pages

-

LDV FILTER KITS

4 Pages

-

Engine Liquid Filtration

154 Pages

-

Cabin Air Filtration

2 Pages

-

ToriT®powercore®dusT collecTors

16 Pages

-

PLEATED BAGS

3 Pages

-

DALAMATIC ® DUST COLLECTORS

12 Pages

-

HPK05

6 Pages

-

Engine Intake Systems

171 Pages

-

Ultrabev P-PF-BEV

4 Pages

-

Capsule Filters

8 Pages

-

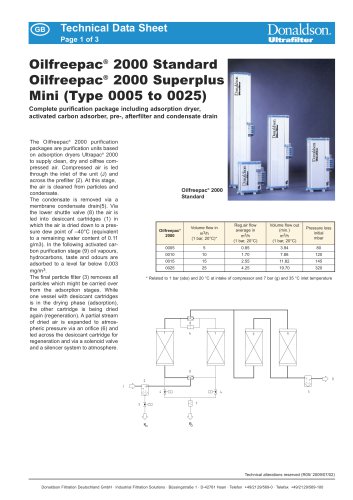

Oilfreepac® 2000 Standard

3 Pages

-

Clean Fuel Cart X011407

1 Pages

-

Clean Fuel Cart X011408

1 Pages

-

Leakage Detector DLD

2 Pages

-

SG Standard Filter Housing

7 Pages

-

Bulk Oil Cleaniness Levels

1 Pages

-

Clean Fuel Cart X011431

1 Pages

-

Venting Product Overview

2 Pages

-

Vacuum Cleaners and Sweepers

4 Pages

-

Chemicals Brochure

4 Pages

-

DPF Thermal Regenerator IOM

16 Pages

-

Adsorbent Breather Assembly

2 Pages

-

Adsorbent Pouch Filter

2 Pages

-

Adsorbent Breather Filter

2 Pages

-

Bulk hP

4 Pages

-

ULTRAPOREX SB

2 Pages

-

LITHOGUARD®

2 Pages

-

BSMmax

2 Pages

-

Valves & Solenoids

2 Pages

-

DT filter

22 Pages

-

Off-Line Filtration

14 Pages

-

Sight Glasses

1 Pages

-

Strainers

4 Pages

-

Valves

6 Pages

-

Breathers

14 Pages

-

TT15/30/60

2 Pages

-

SP100/120

4 Pages

-

Low Pressure Filters

64 Pages

-

WL16

4 Pages

-

Medium Pressure Filters

38 Pages

-

W613

4 Pages

-

FPK02

6 Pages

-

HPK02

4 Pages

-

High Pressure Filters

86 Pages

-

panel filter

1 Pages

-

GDX

4 Pages

-

DISK DRIVE SEALS

2 Pages

-

ADSORBENT LABEL FILTER (ALF)

2 Pages

-

Hydraulic Filtration

374 Pages

-

Engine Liquid Filtration

132 Pages

-

Oil/Water Separators

6 Pages

-

SYNTEQ XP M/S

2 Pages

-

Synteq XP

4 Pages

-

Ultrac? AK

2 Pages

-

Ultrapoly? PE

2 Pages

-

ULTRAC A

2 Pages

-

Dryer Package Filters

2 Pages

-

SG Compressed Air Filters

2 Pages

-

AG Compressed Air Filters

2 Pages

-

Rotary Valves

10 Pages

-

Unimaster® Dust Collector

4 Pages

-

Unicell Dust Collectors

6 Pages

-

Downflo Dust Collectors

6 Pages

Archived catalogs

-

Sensor Vents

2 Pages

-

Fluid Analysis

12 Pages

-

Exhaust Product

186 Pages