Catalog excerpts

FILTRATION SOLUTIONS Fluid Analysis Program Fluid analysis is a snapshot of what is happening inside your equipment. It tells you optimizing filtration performance • Safely extend drain intervals identifying minor problems before they become major failures • Maximize asset reliability • Extend equipment life Fluid Analysis Section Index HIAC PODS Portable Oil Diagnostic System .297 Test Kits and Sampling North America The fluid sampling program featured in this section is used by North American located outside of North you contact your local Donaldson distributor about the fluid sampling kits Suggested Sampling Intervals and Methods Fluid analysis is most effective when samples are representative of typical operating conditions. Always take samples at regularly scheduled intervals and from the same sampling point each time. How critical a piece of equipment is to production should be a major consideration for determining sampling frequency.

Open the catalog to page 1

Fluid Analysis Service FILTRATION SOLUTIONS Fluid Analysis Products The Donaldson Advanced Fluid Analysis Kit is designed to monitor component wear, contamination and fluid condition. Benefits of the Fluid Analysis Program • Partnership with a total filtration solutions provider • High quality testing by an ISO 17025 A2LA accredited laboratory • Results available immediately upon sample processing completion • Innovative data management tools that will help you affect change in daily maintenance Sending Samples to your Donaldson Laboratory Fill out the Component Registration Form and...

Open the catalog to page 2

FILTRATION SOLUTIONS Fluid Analysis Service Test Results / Reports from Your Sample Your Donaldson test report color codes individual results by severity the report. It also provides of the cleanliness level of the fluid with a photo micropatch accompanied by theTarget ISO Chart done on each sample. With Donaldson, you're also on track for total program management with problem summary reports, sample processing turnaround tracking and data mining capabilities that allow you to affect positive change in your daily maintenance Get test results almost immediately - Identify significant trends...

Open the catalog to page 3

Fluid Analysis Service FILTRATION SOLUTIONS How to Read the Donaldson Fluid Analysis Report Reading a fluid analysis report can be an overwhelming and sometimes seemingly impossible task without an understanding of the basic fundamentals for interpreting laboratory results and recommendations. Referring to the report descriptions and explanations below will help you better understand your results and, ultimately, better manage a productive, cost- saving reliability program. Customer, Equipment and Sample Information The information submitted with a sample is as important to who is reading...

Open the catalog to page 4

Fluid Analysis Service FILTRATION SOLUTIONS A data analyst's job is to explain and, if necessary, recommend actions for rectifying significant changes in a unit's condition. Reviewing comments before looking at the actual test results will provide a roadmap to the report's most important information. Any actions that need to be taken are listed first in order of severity. Justifications for recommending those actions immediately follow. FLUID ANALYSIS REPORT - 877-458-3313 Data -lagged For observation ooly; Particle Count is at B HóbEftATE LEVEL (LNtl il: ACID NUM&Efr Is HOKKATELV High;...

Open the catalog to page 5

Fluid Analysis Service FILTRATION SOLUTIONS Test Data Test results are listed according to age of the sample—oldest to most recent, top to bottom- apparent. Significant changes are flagged and printed in the gray areas of the report. Samples* appear newest numbered associated with them throughout important physical property. Depending on lube grade, Oxidation measures the breakdown of a lubricant due to age and operating conditions. Oxidation prevents additives from working and therefore promotes increased acid content, as well as increased viscosity. Nitration is an indication of excessive...

Open the catalog to page 6

Fluid Analysis Service FILTRATION SOLUTIONS Photo Micropatch A photo Micropatch is included with each test report and provides digital imagery of the wear debris, contamination and/or filter media particles found in each fluid sample. It is taken at a 100x magnification and includes the sample's ISO code and a 10 micrometer scale for particle size comparison. PROCESS. HTdKAULlC STATION 14 COMPANY INFORMATION MICRO PATCH MagnlRcMlon: 100 x Scaler m micrometer* e*r division

Open the catalog to page 7

Fluid Analysis Service FILTRATION SOLUTIONS PROCESS HYDRÉYULLC STATION Í4 UNIT TYPE COMPANY INFORMATION Component Registration Form, it will appear above utilizes a three number system to classify system present measuring greater represents particles third represents those Particle count results are Cleanliness Code. When sampling units for the first time, you must include on Cleanliness Codes specific to each of your applications. These unit-specific codes will then pre-fill on each test report. If target ISO codes ISO field will be determined and pressure rating listed on particle ranges...

Open the catalog to page 8

FILTRATION SOLUTIONS Portable Fluid Analysis Kit The Donaldson Portable Fluid Analysis Kit (Part No. X009329) allows you to conduct immediate on-site particulate and water analysis in as little as ten minutes. Using the patch test method, you can quickly and reliably assign a three- digit cleanliness code per ISO 4406- 1999 to a given fluid sample. Simply pull a 25 ml fluid sample through a patch membrane filter and compare oil sample particle distribution with the Fluid Cleanliness Comparison Guide (included) to assign an ISO Cleanliness Also included is a water test kit that can be used...

Open the catalog to page 9

Portable Fluid Analysis Kit Kit Content and Physical Size: Case Size: Height: 14.5"/368.3mm Width: 19.25"/489mm Depth: 7.75"/197mm Membrane Filter Dispensing Bottle Membrane Holder & Funnel Assembly Sampling Pump Dispensing Bottle Plastic Tubing Water Test Vessel 0.8 micron membrane filters 5 micron membrane filters Kit includes detailed operating instructions and visual comparison guide. 1. Assemble the pump and funnel assembly and screw on empty sample bottle. 2. Place solvent dispensing bottle filter on spout of solvent dispensing bottle. 3. Wash funnel with solvent* and pull solvent...

Open the catalog to page 10All DONALDSON catalogs and technical brochures

-

UFK-L Aftercoolers

2 Pages

-

UFK-W Aftercoolers

3 Pages

-

P-EGS

3 Pages

-

CULINARY & PROCESS STEAM

8 Pages

-

Air Intake Systems

8 Pages

-

Clean DEF Solutions

4 Pages

-

Clean Fuel & Lubricant

32 Pages

-

Exhaust System Solutions

2 Pages

-

Pressure Control Systems

2 Pages

-

Innovative Fuel Systems

2 Pages

-

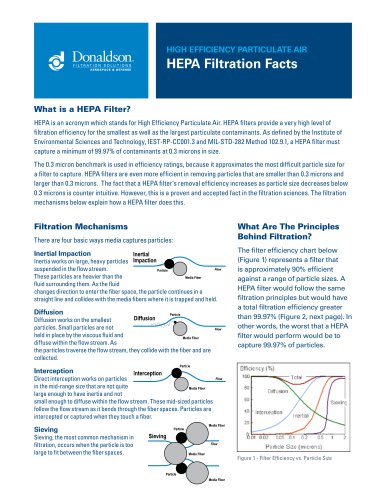

HEPA Filtration Facts

2 Pages

-

AEROSPACE & DEFENSE

4 Pages

-

pOWERCO RE® air cleaners

8 Pages

-

Donaldson Strata™ Tubes

4 Pages

-

PG-EG 0006 – 0192

6 Pages

-

(P)-GS N

6 Pages

-

Minerals Brochure

4 Pages

-

Metals Brochure

4 Pages

-

Industrial Filtration

10 Pages

-

Pharma Industry - Tetratex

2 Pages

-

Microfiltration

2 Pages

-

Power Generation

8 Pages

-

Vacuum Cleaner and Sweepers

4 Pages

-

Hydraulic Filtration

320 Pages

-

LDV FILTER KITS

4 Pages

-

Engine Liquid Filtration

154 Pages

-

Cabin Air Filtration

2 Pages

-

ToriT®powercore®dusT collecTors

16 Pages

-

PLEATED BAGS

3 Pages

-

DALAMATIC ® DUST COLLECTORS

12 Pages

-

HPK05

6 Pages

-

Engine Intake Systems

171 Pages

-

Ultrabev P-PF-BEV

4 Pages

-

Capsule Filters

8 Pages

-

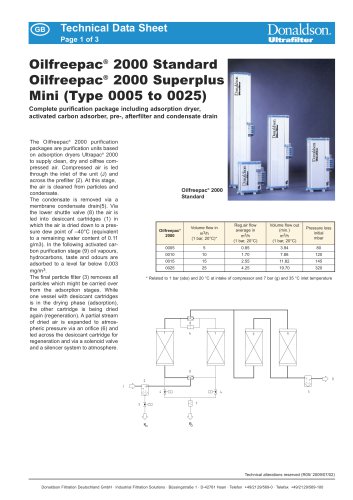

Oilfreepac® 2000 Standard

3 Pages

-

Clean Fuel Cart X011407

1 Pages

-

Clean Fuel Cart X011408

1 Pages

-

Leakage Detector DLD

2 Pages

-

SG Standard Filter Housing

7 Pages

-

Bulk Oil Cleaniness Levels

1 Pages

-

Clean Fuel Cart X011431

1 Pages

-

Venting Product Overview

2 Pages

-

Vacuum Cleaners and Sweepers

4 Pages

-

Chemicals Brochure

4 Pages

-

DPF Thermal Regenerator IOM

16 Pages

-

Adsorbent Breather Assembly

2 Pages

-

Adsorbent Pouch Filter

2 Pages

-

Adsorbent Breather Filter

2 Pages

-

Bulk hP

4 Pages

-

ULTRAPOREX SB

2 Pages

-

LITHOGUARD®

2 Pages

-

BSMmax

2 Pages

-

Valves & Solenoids

2 Pages

-

DT filter

22 Pages

-

Off-Line Filtration

14 Pages

-

Sight Glasses

1 Pages

-

Strainers

4 Pages

-

Valves

6 Pages

-

Breathers

14 Pages

-

TT15/30/60

2 Pages

-

SP100/120

4 Pages

-

Low Pressure Filters

64 Pages

-

WL16

4 Pages

-

Medium Pressure Filters

38 Pages

-

W613

4 Pages

-

FPK02

6 Pages

-

HPK02

4 Pages

-

High Pressure Filters

86 Pages

-

panel filter

1 Pages

-

GDX

4 Pages

-

DISK DRIVE SEALS

2 Pages

-

ADSORBENT LABEL FILTER (ALF)

2 Pages

-

Hydraulic Filtration

374 Pages

-

Engine Liquid Filtration

132 Pages

-

Oil/Water Separators

6 Pages

-

SYNTEQ XP M/S

2 Pages

-

Synteq XP

4 Pages

-

Ultrac? AK

2 Pages

-

Ultrapoly? PE

2 Pages

-

ULTRAC A

2 Pages

-

Dryer Package Filters

2 Pages

-

SG Compressed Air Filters

2 Pages

-

AG Compressed Air Filters

2 Pages

-

Rotary Valves

10 Pages

-

Unimaster® Dust Collector

4 Pages

-

Unicell Dust Collectors

6 Pages

-

Downflo Dust Collectors

6 Pages

Archived catalogs

-

Sensor Vents

2 Pages

-

Exhaust Product

186 Pages