Catalog excerpts

Machines Blades Fluids Sawing Solutions Products that are a cut above the rest! 5505 W 123rd St Savage, MN. 55378 www.doallsawing.com 888-362-5572

Open the catalog to page 1

Introducing the newest member of the DoALL Sawing Products Tilt Frame Family... The TF-141B Manual vise The newest vertifcal tilt frame saw, the TF-1418 is designed to be an affordable option for small to medsize fabrication operations. This versatile saw can tilt 60 degrees left and 45 degrees right. Materials can be fed from either the left, right or front making it perfect for a variety of cuts. The TF-1418 has a capacity of 14" x 18" and cuts solid or tube steel. Band speed Table Capacity Band tension Feed control Infinitely variable, Adjustable Feed Rate and feed force DoALL Blue

Open the catalog to page 2

DoALL University A New Way to Deliver Added Value for DoALL Customers, Operators and Suppliers To date, the DSP Factory Regional Managers have successfully held DoALL University classes for DGI personnel in Savage, Houston, Omaha and Glendale, CA. Upcoming classes will be held in Anich, Harrisburg and Chicago. DoALL Factory Regional Mangers have had such a tremendous success with this value added training class, with demand it continues to be scheduled with existing customers, potential customers, and customers with competitive sawing equipment and DoALL distribution. The DoALL University...

Open the catalog to page 3

Solutions for All Your Sawing Needs... Whether you’re a metal service center, fabrication or machine shop, or work in a maintenance department or tool room, there’s a DoALL saw that will meet your specific requirements. Our wide range of sawing machines includes general purpose saws, vertical contour saws, miter cutting saws, and production power saws with capacities up to 32-in. diameter. The following pages provide an overview of our standard machine product offering. How to Select & Order the Right Band Saw Machine Use the chart on page 3 as a guide to select the right saw for typical...

Open the catalog to page 4

Start Here Miter Cuts Bundle Cuts Bundle Cuts Bundle Capacit

Open the catalog to page 5

General Purpose Saws_ In machine shops, tool rooms, maintenance departments and low volume production operations, SAWING PRODUCTS nothing beats DoALL's general purpose saws for long life, reliability and accuracy. These models will cut a wide range of materials such as plastic, wood, aluminum, tool steel and more. Horizontal Series Dual Column Series Production Power Saws_ These saws are designed for cutting a wide range of metals on a production basis. They offer automatic operation and numerical control, and feature solid, heavy-duty construction. This provides more rigidity and reduces...

Open the catalog to page 6

Production Power Saws_ These saws are designed for cutting a wide range of metals on a production basis. They offer automatic operation and numerical control, and feature solid, heavy-duty construction. This provides more rigidity and reduces vibration for higher cutting rates, exceptional accuracy, superior surface finish and increased blade life. SAWING PRODUCTS Horizontal Series Dual Column Series

Open the catalog to page 7

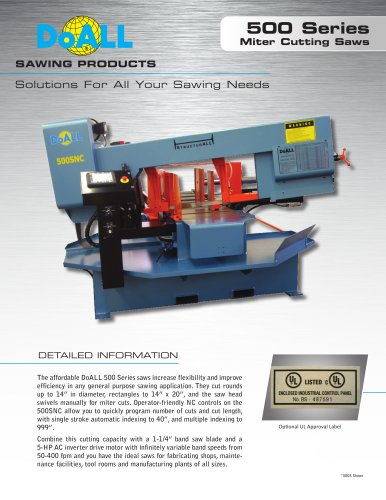

Miter Cutting Saws DoALL miter cutting saws will increase flexibility and improve efficiency in fabrication shops or in other sawing applications requiring the cutting of miters. Models feature cutting capacities to 26-in. diameter rounds and rectangles to 26 x 39-1/2-in. with angle cutting capabilities to 60°. SAWING PRODUCTS Horizontal Series Vertical Series Dual Column Swivel Series

Open the catalog to page 8

Vertical Saws Among the most versatile machines available, vertical contour saws can cut aluminum, brass, copper, mild steel, tough tool steel, stainless steel and sheet metal as well as nonmetals like plastics, wood, paper and fibrous materials. Plus, they're available with a wide variety of attachments for contour cutting, miter cutting, disc cutting and more. SAWING PRODUCTS Contour Series Ask about these and other accessories for your vertical band saw! HMD Power Feed Tables Hydraulic Tables Friction Si Diamond Saws Zephyr Series Diamond Series

Open the catalog to page 9

Selecting the Right Blade Step 1. Choose a Blade Style. Use the blade style table below to select a blade style for the material(s) you are cutting. The table gives the page number where each blade style is detailed. Step 2. Determine a Blade Pitch. Use the Bi-Metal or Tungsten Carbide blade pitch table on the next page to determine the correct pitch for the size of your work. Step 3. Determine a Blade Width. Most machines accept only one blade width. For contour sawing, choose the widest blade that can cut the smallest work radius. Once you have made these choices, turn to the blade style...

Open the catalog to page 10

Ordering the Right Blade The part number you will use in ordering is a combination of the catalog number and three numbers that indicate the blade length, as explained below. • To order welded bands, attach the band length in inches to the end of the catalog number. Example: If you want a 180 inch welded band of catalog number 302-961, order part number 302961180. (For bands 99 inches or shorter, lead with a zero. For example, to order a 93 inch welded band of catalog number 302- 961, order part number 302961093.) • To order a coil of blade, attach the ordering code from the table below to...

Open the catalog to page 11

DoALL Band Saw Blades With the widest and deepest selection of band saw blades in the industry, DoALL Sawing Products can provide the best blade for any sawing application. Our selection of bi-metal, tungsten carbide, carbon, knife edge and diamond grit edge blades should be your first choice when finding the right Whether you're cutting solids or structurals, mild steel, exotic alloys, silicon, glass, wood, plastic or foam, DoALL has a solution. There's nothing we can't cut. Knife Edge Blades For slicing soft, low-density medium-density material SAWING PRODUCTS low-density materials For...

Open the catalog to page 12

Carbon Steel Blades Metal Master™ SAWING PRODUCTS For general purpose sawing easily machined metals Flex Back Precision Tooth Claw Tooth For non-production sawing highly machinable materials Hard Back Precision Tooth Buttress Tooth Claw Tooth Wave Set + Straight Set For high-speed friction sawing of ferrous metals For contour and cut-off sawing Spring Back

Open the catalog to page 13All DoALL Sawing Products catalogs and technical brochures

-

Vertical Contour Band Saws

4 Pages

-

F_CuttingFluids

2 Pages

-

M_C-4100series

2 Pages

-

M_Vert_Contour

3 Pages

-

SawingMachines

4 Pages

-

BimetalCarbide_lorez

8 Pages

-

Saw Blade Catalog

27 Pages

-

2613-V3 Vertical Contour Saw

2 Pages