Catalog excerpts

DILAS, the diode laser company, manufactures high-power diode laser components and systems in a wide range of output powers and wavelengths including fiber-coupled, direct beam and integrated solutions. Today, with over 200 employees, DILAS’ strengths are in quality engineering, process control, product development and volume manufacturing of a world-class product line for medical, diode-pumped solid-state lasers, defense, graphic arts and materials processing applications.

Open the catalog to page 2

Founded in 1994 in Mainz, Germany, DILAS looks back at a record of continued growth.

Open the catalog to page 3

Long Standing Commitment DILAS’ product development goes hand in hand with market needs always in accordance with customer specification. ΩΩ DILAS maintains ISO-9001 certified facilities with the highest standards for quality, reliability and performance.

Open the catalog to page 4

Global Presence In 2005 DILAS Diode Laser Incorporated was founded in Tucson, Arizona, to serve the North American market and to manufacture for U.S. government programs. ΩΩ In 2008 DILAS Diodelaser China Co., Ltd. was founded in Nanjing City to serve the growing Asian markets. DILAS establishes a worldwide network of sales and service partners.

Open the catalog to page 5

Through extensive research and development, we are working to transform the world through innovative products and solutions that meet the needs of customers. We invest ten percent of our annual revenue in research and development.

Open the catalog to page 6

Product development is supported by an in-house machine shop to facilitate fast and precise manufacturing.

Open the catalog to page 7

Our strength lies in our fully automated state-of-the-art facilities for precision manufacturing needed to meet the requirements for highpower diode lasers. DILAS has an edge when it comes to giving its customers the best yields of our products. We are determined in solving customer needs and providing quality products in the marketplace.

Open the catalog to page 8

Quality is the highest priority at DILAS and is controlled throughout the entire manufacturing process.

Open the catalog to page 9

Incoming Inspection 100% inspection of all parts is performed. All supplied parts are measured carefully before they are used in production. ΩΩ Incoming inspection ensures high consistency and quality. The control of mechanical parts on a micrometer level is a DILAS standard, as well as the surface quality control of all optical components.

Open the catalog to page 10

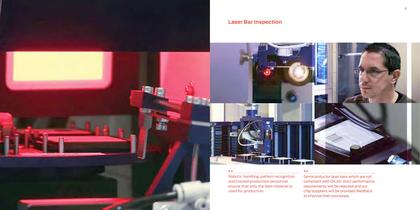

Robotic handling, pattern recognition and trained production personnel ensure that only the best material is used for production. Semiconductor laser bars which are not compliant with DILAS’ strict performance requirements will be rejected and our chip suppliers will be provided feedback to improve their processes.

Open the catalog to page 11

Clean Room Production In the entire production area, cleanliness is key. Each employee wears clean room gowns to ensure an uncontaminated environment. Via the gowning room the employees reach the clean room production area. A special test ensures that electrostatic discharge is prevented. Clean surfaces are also a key factor for metal parts which undergo electro-chemical plating procedures. We maintain class 1000 or better in all areas. A class 100 clean room environment is guaranteed under the flow hoods at the work benches.

Open the catalog to page 12

Plating of nickel and gold is commonly used in DILAS’ manufacturing. In ultra-high vacuum evaporation systems, the solder material is applied to the heat sinks. Heat sinks are placed in special holders with aligned masks to allow the precise deposit of solder material. The thickness of the platings and the solder is controlled by x-ray thin-film measurement equipment.

Open the catalog to page 13

Electro-Optical Assembly High-precision laser bar placement together with mature soldering processes ensure best laser bar performance and lifetime. Electrical contacts to the diode laser chip are made by solder or wire bonds. DILAS’ mounting procedures guarantee exact positioning and highest flatness of the laser bars. DILAS currently delivers up to 2000 laser bars per week with capacity for continued growth.

Open the catalog to page 14

Visual Inspection 100% visual inspection by automation and pattern recognition. ΩΩ High-precision equipment is used to measure all relevant electro-optical parameters of diode laser bars and modules.

Open the catalog to page 15

Automated measurement is done before and after burn-in which eliminates handling, ensuring high throughput. ΩΩ In DILAS’ burn-in racks all diode laser bars and modules are operated according to customer conditions.

Open the catalog to page 17

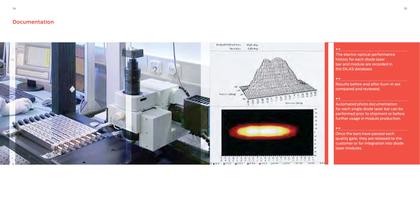

The electro-optical performance history for each diode laser bar and module are recorded in the DILAS database. ΩΩ Results before and after burn-in are compared and reviewed. ΩΩ Automated photo documentation for each single diode laser bar can be performed prior to shipment or before further usage in module production. ΩΩ Once the bars have passed each quality gate, they are released to the customer or for integration into diode laser modules.

Open the catalog to page 18

Optics Mounting High-precision semi-automated alignment of optical elements ensures consistency and high-performance beam shaping. Six-axis control and sophisticated processes combined with the experience of DILAS’ employees are the basis for the consistent volume production of diode laser modules. DILAS’ micro-optical mounting ensures fast-axis or both-axis collimation, homogenization and fiber coupling of laser bars and modules.

Open the catalog to page 19

Fiber Coupling Whether it is a single-bar or multi-bar arrangement, DILAS performs fiber coupling for applications in medical laser treatment, solid-state and fiber-laser pumping, and materials processing. ΩΩ DILAS’ products offer highest output powers in smallest fiber core diameters. ΩΩ Precise beam properties are measured for high-precision applications.

Open the catalog to page 20

Module Production In the module production, single diode laser bars are integrated into diode laser modules. Fine mechanics and skilled technicians combined with proper handling and the scalability concept allow the combination of up to thousands of laser bars to a single module for very high-power applications.

Open the catalog to page 21

Module Production Within our assemblies, pre-tested single bars can be combined to diode laser modules with predictable performance.

Open the catalog to page 22All DILAS catalogs and technical brochures

-

Fiber Cables

1 Pages

-

MINI Diode Laser System

3 Pages

-

8W CW

2 Pages

-

Single Bar Modules

2 Pages

-

OEM Engines, 3000W CW

2 Pages

-

Vertical Homogenizer 808nm

2 Pages

-

Tailored-Bar Modules 976nm

2 Pages

-

Tailored-Bar Modules 793nm

2 Pages

-

Tailored-Bar Modules 638nm

2 Pages

-

Product Brochure

11 Pages

-

Line Focus Diode Laser System

2 Pages

-

COMPACT Diode Laser System

4 Pages