Catalog excerpts

Magnum Mulcher To suit High Flow Skid Steer Loaders & Excavators up to 20T Magnum Mulcher The Digga Magnum Mulcher provides High Flow Skid Steer Loaders & Excavators up to 20 tonne with the versatility of grinding small and large material, trees or brush, even above ground stumps with just one operator. Debris can be mulched back into the soil for faster decomposition. Magnum is the perfect value adding attachment for clearing firebreaks, land clearing, maintenance of park or forestry trails, vegetation management and re-mediation. Features: • Hydraulic driven, self aligning belt drive; low maintenance and great durability. • Fixed hammers with replaceable carbide teeth. • Shreds up to 8” diameter hardwood trees. • Designed to operate at 2,000 RPM. • Adjustable push bar. • Optional oil cooler available in both field and/or factory installation. • Replaceable abrasion resistant AR400 wear plate on skid shoes. • On-board pressure gauge easily viewed from operators station to monitor system pressure (N/A MM60E models). • Deflector door standard to control particle size and discharge direction (optional for MM60E). Machine Type Skid Steer Cutting Width Number Teeth High Flow Skid Steer Loaders & Excavators up to 20T. Machine suitability: Complete with hoses, couplers, multi-fit frame, Integrated Oil Cooler and pressure gauge. Ability to adjust hydraulic motor flow to match the output of the host machine. Increases Production by cooling hydraulic oil and virtually eliminate down time required to let machine cool down. Unique Chevron design 200HP drive belt and sprockets eliminate slippage. Patented reversible split tooth design channels cut material through the centre of the teeth providing relief and consistent cut material. 3/4 inch Drum wall thickness. Five reinforcing stabilizers reducing rotor flex, resulting in increased bearing life. New “push” type adapter sleeve traps the bearing against a shoulder on the rotor shaft which prevents the rotor to float axially in the mainframe. Increases production by reducing recovery time. Protects the host machines hydraulic system from damage due to constant overheating. Eliminates the need for tensioning devices, reduces load on bearings. Reduces drag on motor increasing production. Through shaft design adds to rigidity. Guaranteed a positive grip on the rotor shaft that will never come loose in the event of a heavy shock load or an unintentional axial load. Significantly reduces down time and maintenance costs Reversible tooth allows for quick field replacement without downtime. Adjustable Bent Axis Motor Unique Drive Belt Patented Tooth Design Heavy Duty Rotor Design New Shaft And Bearing Design The new design also prevents dirt from making its way to the bearings. Email: info@digga.com Web: www.digga.com

Open the catalog to page 1All DIGGA catalogs and technical brochures

-

CUSTOM AUGERS

1 Pages

-

Auger Extensions - XO4

1 Pages

-

Augers - A4-RC4-DR4

1 Pages

-

Augers - Agricultural

2 Pages

-

Digga Mini Turf Cutter

1 Pages

-

Hydrive

1 Pages

-

Cement Mixa

1 Pages

-

Skid Hoe

1 Pages

-

Vibratory Roller

1 Pages

-

Spreader Bar

1 Pages

-

Pallet forks

1 Pages

-

Digga Profile

1 Pages

-

Cleana Bucket Broom

1 Pages

-

Standard 4 in 1 Bucket

1 Pages

-

Digga Bigfoot Trencher

1 Pages

-

Swing control

1 Pages

-

Mini Auger Extension Range

1 Pages

-

Wearparts Fitting Chart

1 Pages

Archived catalogs

-

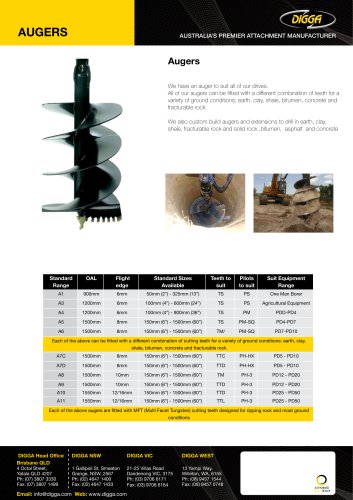

Augers

1 Pages

-

Augers driver

9 Pages

-

PROFILA SP300 STANDARD FLOW

1 Pages

-

Mini Trencher

1 Pages

-

Bigfoot Trenchers

1 Pages

-

Excavator Digga

16 Pages

-

SkidSteer - Digga

12 Pages