Catalog excerpts

SEALING SOLUTIONS FOR THE HYDRAULICS INDUSTRY /^iFREUDENBERC INNOVATING TOGETHER

Open the catalog to page 1

Industry-specific and customized service concepts 6 Product portfolio of the Dichtomatik brand 7 HYDRAULIC COMPONENTS Structure and sealing components of a hydraulic cylinder Introduction to the designations Dimensions SEALING FUNCTIONS INSTALLATION SPACES AND CONSTRUCTIVE RECOMMENDATIONS Examples for use in specified installation spaces 16 Assembly - what needs to be considered 18 Special features for the material PTFE 20 Guide elements, pistons and rods 27 The information contained herein is considered to be reliable, but no assurances, warrants or guarantees whatsoever, of any kind, are...

Open the catalog to page 2

The Freudenberg Group was founded in 1849 and is still owned by the approximately 300 descendants of the c ompany founder. The resulting financial stability and social awareness are decisive success factors that create trust. Today, Freudenberg is a global, broadly diversified group of companies divided into Business Groups that operate in a wide variety of sectors. The company has always been c onsidered an innovation and technology leader, from Vileda® brand household products to technically complex sealing solutions. Freudenberg Sealing Technologies (FST) is the largest B usiness Group...

Open the catalog to page 3

INDUSTRY-SPECIFIC AND CUSTOMIZED SERVICE CONCEPTS PRODUCT PORTFOLIO OF THE DICHTOMATIK BRAND ONLINE ORDERING PLATFORM EASY STATIC APPLICATIONS TRANSLATIONAL MOVEMENTS The EASY online ordering platform enables easy order p rocessing, as well as price, delivery time and stock queries around the clock. Besides detailed product information, installation space and cross-sectional drawings are a vailable for download. The EASY Business Connector is used to transfer your orders directly to your SAP system. This ensures that you are always up to date on the status of your order. Register today if...

Open the catalog to page 4

HYDRAULIC COMPONENTS Sealing components for hydraulic applications are used to seal linear/reciprocating moving components. Sealing elements are selected according to the application at hand and its operating parameters, such as pressure, speed, hydraulic medium and operating temperature. STRUCTURE AND SEALING COMPONENTS OF A HYDRAULIC CYLINDER THE COMPONENTS USED IN HYDRAULICS INCLUDE • Piston seals • Piston rod seals/rod seals • Wipers • Guiding elements • O-Rings The requirements for the application are the decisive factor for selecting the seal profile and other seal components. Other...

Open the catalog to page 5

DIMENSIONS Designations of our hydraulic seals Our nomenclature N = U-Cup K = Piston seal S = Rod seal A = Wiper F = Guide elements Types Within the assemblies listed above, we distinguish between the following types: Rod seals, piston seals, wipers and guide elements are always defined according to the installation space dimension. This means that the size specifications of the seal correspond to the sizes of the installation space and that the installation space and not the seal is always measured. We also provide the H dimension (measured width of the seal) for many of our piston and rod...

Open the catalog to page 6

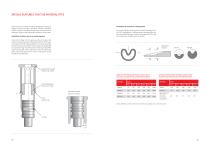

THE SEALING MECHANISM OF ROD SEALS – DYNAMIC SEALING MECHANISM The critical point of a hydraulic system is the rod seal. Leakage of hydraulic fluid from the cylinder would prevent trouble-free operation and lead to environmental damage, among other things. The sealing mechanism between the dynamic sealing lip and the rod is based on the hydrodynamic processes in the sealing gap. When the sealing system starts to move, the liquid film is drawn off by the sealing lip. The resulting drag flow and hydrodynamic pressure buildup create the dynamic sealing gap. What remains is a thin lubricating...

Open the catalog to page 7

The following principles apply to the design of the installation space and should be strictly observed for trouble-free operation and a long service life of the seal: • rounded corners in the groove base (1) ensure correct seating of hydraulic seals • rounded groove flank transitions (2) reduce the risk of gap extrusion • the surface finish of the groove base (3) and the groove flanks (4) ensure a good sealing function • compliance with the tolerances for the groove width (5), the installation chamfer (6) and the correct dimensions of the sealing gap on the non-pressure side (7) • the...

Open the catalog to page 8

Compact seal type K Piston The radius R for wiper designs AE40 and AE42 is selected as follows, depending on the height of the wiper: H [mm] < 12 16 18 For wiper types AE41, AE47, AD48 and AD51, the radius is always R = 0.5 regardless of the wiper height. Roof collar sets type KDS 01, SDS 01 The AD60 and AD61 wipers require an axially accessible installation space with small diameters. With larger diameters, a closed installation space can be provided. Subsequent calibration is recommended. Please refer to the following table for dimension G and radius R: When using double wipers, depending...

Open the catalog to page 9

Even though the materials used for Dichtomatik brand hydraulic seals deliver excellent performance and are robust, special care is required during installation. Mechanical damage, especially to the sealing edge, can lead to leakage. In addition, each seal must be checked before installation for damage or aging that may have already occurred during transport or storage. Instructions for mounting: 1. In the case of single-acting seals, the seal must be installed with the preload side facing the pressure side 2. Insertion chamfers are absolutely necessary on the cylinder barrel and piston rod....

Open the catalog to page 10

Since PTFE has virtually no elastic properties, PTFE-pre-loaded sealing elements (SPOR30, SPOR31, KPOR30, KPOR31) must be installed with particular care and then be calibrated. Observe the following installation instructions: Installation of piston seals in an enclosed groove Insert the O-Ring into the groove without torsion: We recommend the procedure already described for PTFE seals. In this case, the PTFE ring is pushed over a conical assembly aid with an expansion sleeve until it snaps into the groove to expand the ring. The deformation of the expanded PTFE ring is accelerated with a...

Open the catalog to page 11All DICHTOMATIK SAS catalogs and technical brochures

-

RADIAL SHAFT SEALS

3 Pages

-

ROD SEALS

3 Pages

-

PISTON SEALS

2 Pages

-

O-RINGS

2 Pages

-

O-RING TOLERANZES

13 Pages

-

NON-METALLIC GASKETS

2 Pages

-

DICHTOMATIK O-RINGS

44 Pages

-

FOOD & BEVERAGE SEALS

1 Pages

-

END CAPS

2 Pages

-

DICHTOMATIK BRAND KIT OFFERINGS

20 Pages

-

BACKUP RINGS

1 Pages

-

AXIAL SEALS

2 Pages

-

STANDARD ARTICLE OVERVIEW

5 Pages

-

BONDED SEALS

2 Pages

-

RADIAL SHAFT SEALS

23 Pages

-

O-RINGS

44 Pages

-

CAPABILITY STATEMENT

12 Pages