Catalog excerpts

DP02 PLASTIC PUMP USER MANUEL USER MANUAL DP02 PLASTIC PUMPS

Open the catalog to page 1

DP02 PLASTIC PUMP USER MANUEL AIR- OPERATED DOUBLE DIAPHRAGM PUMPS

Open the catalog to page 2

DP02 PLASTIC PUMP USER MANUEL TABLE OF CONTENT PUMP’S PERFORMANCE CURVES 4 AIR LINE MOISTURE AIR INLET AND PRIMING PUMPING HAZARDOUS LIQUIDS DIAPHRAGM MAINTENANCE PLASTIC CHECK VALVE MAINTENANCE PUMP’S DIMENSIONS PUMP’S PACKING PUMP’S SPARE PARTS DRAWS PUMP’S SPARE PARTS LIST MATERIALS CODES DIAPHRAGM MATERIALS PRINCIPLE OF PUMP OPERATION INSTALLATION & START UP AREAS OF APPLICATION AIR CONNECTION AIR VALVE LUBRICATION

Open the catalog to page 3

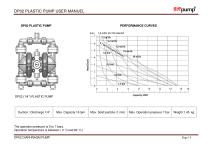

DP02 PLASTIC PUMP USER MANUEL PERFORMANCE CURVES The operation pressure is 0 to 7 bars. Operation temperature is between ( 0 ˚C and 82 ˚C.) DP02 DIAPHRAGM PUMP

Open the catalog to page 4

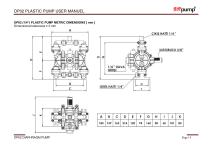

DP02 PLASTIC PUMP USER MANUEL DP02 (1/4”) PLASTIC PUMP METRIC DIMENSIONS [ mm ] Dimensional tolerances ± 3 mm

Open the catalog to page 5

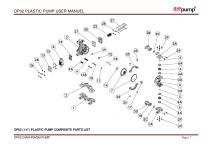

DP02 PLASTIC PUMP USER MANUEL DP02 (1/4”) PLASTIC PUMP COMPOSITE PARTS DRAWING DP02 DIAPHRAGM PUMP

Open the catalog to page 6

DP02 PLASTIC PUMP USER MANUEL DP02 (1/4") PLASTIC PUMP COMPOSITE PARTS LIST DP02 DIAPHRAGM PUMP

Open the catalog to page 7

DP02 PLASTIC PUMP USER MANUEL 1 Suction Line Suction Line Suction Line Elbow Suction Line Elbow Suction T Flanged Suction T Flanged Discharge Line Discharge Line Discharge Line Elbow Discharge Line Elbow Discharge T Flanged Discharge T Flanged Bracket Gasket Main Body Outer Chamber Outer Chamber Check Ball Check Ball Check Ball Check Ball Check Ball Check Ball Check Ball Check Ball Seat Check Ball Seat Check Ball Seat Check Ball Seat Check Ball Seat Gasket Check Ball Seat Gasket Diaphragm Diaphragm Diaphragm Diaphragm Diaphragm Diaphragm Diaphragm Air Valve Repair Kit Sleeve, Pilot Valve...

Open the catalog to page 8

DP02 PLASTIC PUMP USER MANUEL Aluminum Cast Iron 316 Stainless Steel Polyproplene Polyproplene with Fiberglass PVDF Polyethylene PVC Bronze 316L Stainless Steel Neoprene Santoprene Buna-N EPDM Silicon PTFE Viton (FKM) Dia Special Material Brass Metal Steel DIAPHRAGM MATERIALS AND OPERATION TEMPERATURES DP02 DIAPHRAGM PUMP

Open the catalog to page 9

DP02 PLASTIC PUMP USER MANUEL Maksimum Neoprene It is resistant to the vegetable oils. Its abrasion resistant is very good. The fluids like acids, esters, ketones can cause damages to the material of construction and therefore they are not recommended. Buna-N It is generally used for oils. It is very durable to the transfer of water and hydraulic oil. EPDM It is durable to chemicals. It is not durable to oil and solvents. It has moderate resistance to the alcohols and ketones. PTFE It is generally used for heavy chemicals and acids. It features good resistance. It is suitable for heat...

Open the catalog to page 10

DP02 PLASTIC PUMP USER MANUEL PRINCIPLE OF PUMP OPERATION The diaphragm pump is consisted of two diaphragm chambers and two diaphragms. The diaphragms are connected to each other with a diaphragm rod and move in a reciprocating action. As one diaphragm performs the discharge stroke, the other diaphragm which is connected with the rod is pulled to perform the suction. At the end of the stroke, an air distribution valve automatically shifts, reversing the entire sequence, filling and pumping from alternate chambers. Mutual movements that repeated continuously ensure suction and discharge...

Open the catalog to page 11

DP02 PLASTIC PUMP USER MANUEL INSTALLATION & START-UP The interconnections of the diaphragm pump are straightforward. The fluid is taken from the bottom manifold and discharged at the upper manifold. Diaphragm pumps are characterized by turbulence flow. To prevent turbulence flow, the flexible hoses are installed upstream the suction and the discharge port. In order to observe the pressures at the suction and discharge parts of the pump and adjust the flow rate, the manometers and valves are attached at the suction and discharge ports. When one or both valves are closed down, the pump will...

Open the catalog to page 12

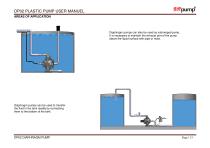

DP02 PLASTIC PUMP USER MANUEL AREAS OF APPLICATION Diaphragm pumps can also be used as submerged pump. It is necessary to maintain the exhaust port of the pump above the liquid surface with pipe or hose. Diaphragm pumps can be used to transfer the fluid in the tank readily by connecting them to the bottom of the tank.

Open the catalog to page 13

DP02 PLASTIC PUMP USER MANUEL Diaphragm pumps can also be used as barrel pumps. They have effective suctions ability and able to transfer all the fluid in the barrel. The diaphragm pumps are able to transfer fluids at 6 meter of deepness. Cavitation might obstruct the operation. To prevent this, the air in the hose between the pump and fluid should be discharged.

Open the catalog to page 14

DP02 PLASTIC PUMP USER MANUEL AIR CONNECTION The air pressure should not be in excess 7 bars. The pump should be provided with the air supply at such pressure and flow to achieve desired performance. When the air supply line is solid piping, use a short length of flexible hose not less than ½" in diameter between the pump and the piping to reduce strain to the piping. The weight of the air supply line, regulators and filters must be supported by some means other than the air inlet cap. Otherwise, unsupportive weight may result in damage to the pump. A pressure regulating valve should be...

Open the catalog to page 15

DP02 PLASTIC PUMP USER MANUEL PUMP PROBLEMS AND SOLUTIONS PROBLEM: The pump fails to operate even the air is supplied. The supplied air is directly exit through the exhaust filter. PROBLEM: The pump transfers the fluid, but the flow is fluctuating. SOLUTION: Check the air valve of the pump. The piston of the linerpiston assembly of the air valve may be jammed. Disassembly the air valve then remove, clean and lubricate the piston of the liner-piston assembly. Wipe off and lubricate the liner. Install the piston in the liner and break in a while. Install the air valve back and start the pump....

Open the catalog to page 16

DP02 PLASTIC PUMP USER MANUEL IMPORTANT Read these safety warnings and instructions in this manual completely, before installation and start-up of the pump. It is the user’s responsibility to retain this manual. Any operation performed that is not in according to the information provided under the manual may render the pump’s warranty invalid. WARNINGS WARNING: Check all the connections with gaskets for any looseness before operating the pump. Any loose connection must be tightened to prevent any leakage WARNING: Check all capscrews and ring nuts for tightness before operating the pump for...

Open the catalog to page 17All DİAPUMP POMPA ve MAK. SAN. TİC. LTD. ŞTİ. catalogs and technical brochures

-

DP 30 METAL & PLASTIC PUMPS

35 Pages

-

DP 100

1 Pages

-

DP 10 METAL & PLASTIC PUMPS

35 Pages