Catalog excerpts

Diamond Z Electronic Control System • The NEMA4 rated machine control PLC coupled with the NEMA 4 rated LCD screen built by Murphy for Eaton makes this control system one of the most efficient state of the art control system available to day. • Coupled with precision programing and a clear, experienced understanding of grinding mechanics and engine management further enhance the benefit to the performance and self diagnostic capabilities of all of our machines. • This system takes the place of standard engine analog gauges, the engine messenger reader screen as well as all the caution and warning lights. • The screen also offers the convenience of illustrating exactly what and when the control plc is telling the machine to do for ease of operation and trouble shoo

Open the catalog to page 1

• This state of the art control system will allow the operator to become much more familiar with his machine while gaining a better understanding of exactly how the machine functions. • Added features allow you to track not only your required service intervals but also the job hours and all of your critical component data. • The self diagnostic screen will tell you if you have an over load, amperage draw, short or multiple other potential electrical malfunctions. • All of this and more but the most amazing part of this system is everything functions exactly as designed even with out the...

Open the catalog to page 2

MAIN DEFAULT AND OPTIONAL GAUGE SCREENS

Open the catalog to page 3

MAIN POWER UP DEFAULT SCREEN

Open the catalog to page 4

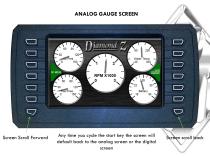

Screen Scroll Forward ANALOG GAUGE SCREEN RPM X1000 Any time you cycle the start key the screen will default back to the analog screen or the digital Screen scroll back

Open the catalog to page 5

DIGITAL GAUGE SCREEN

Open the catalog to page 6

SETTINGS SCREEN FOR SETTING THE SCREEN TYPE FROM ANALO TO DIGITAL: OR CHANGE YOUR PASSWORD. Home Screen Analog Change Password

Open the catalog to page 7

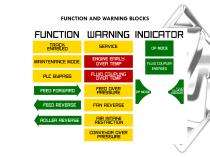

FUNCTION AND WARNING BLOCK SCREEN EXAMPLES

Open the catalog to page 8

FUNCTION AND WARNING BLOCKS FUNCTION WFIRNING

Open the catalog to page 9

MAIN SCREEN WITH FUNCTION BLOCKS ILLUSTRATED

Open the catalog to page 10

MAIN SCREEN WITH WARNING BLOCK ILLUSTRATED

Open the catalog to page 11

DIGITAL GAUGE SCREEN IS SHOWING THE FLUID COUPLER FUNCTION ENGAGED Water Temp Fuel Pressure Battery

Open the catalog to page 12

FEED FDRlilRRD Water Temp FLUID CDUPLER ENGRGEO

Open the catalog to page 13

Water Temp Fuel Pressure

Open the catalog to page 14

DIGITAL SCREEN SHOWING FEED REVERSE & FEED SPEED WITH FLUID COUPLER OFF

Open the catalog to page 15

MAINTENANCE MODE MHINTENRNlE mode Water Temp □c !_ _l Battery Maintenance mode is enabled when tub/crush roller are hydraulically pin in the safe maintenance position. When in this position the mill will no engage

Open the catalog to page 16

Faults, cautions and warnings

Open the catalog to page 17

Digital Screen will flash every 2sec showing Data Connection Lost: Will need to check the Data link coming to the screen? The machine will function with Data Connection lost.

Open the catalog to page 18

LDNVEyDR DVER Digital Screen flashes every 2sec Showing Conveyor Over Pressure: This Will Shut the Feed System OFF. After the Conveyor Pressure Drops be low 1800psi the screen will go back to Normal and Feed will resume.

Open the catalog to page 19

This Screen Flashes ever 2sec while the feed system is over pressure. (TUB)After 3.5sec the feed system will auto reverse for 2.5sec. Then go back forward. (DZH) After 2sec the feed will auto reverse for 1sec.

Open the catalog to page 20

With the PLC in Bypass the feed system will turn in either direction at any RPM

Open the catalog to page 21

MILL COVER/CRUSH ROLLER OR TUB IS UNSECURED

Open the catalog to page 22

THIS SCREEN FLASHES EVERY 2 SEC SHOWING EMERGENCY KILL HAS BEEN SET. RESET KILL SWITCH PRIOR TO ENGAGING THE START SWITCH.

Open the catalog to page 23

THIS ANALOG GAUGE FLASHES EVERY 2 SEC FOR ENGINE EARLY OVER TEMP WARNING IF ENGINE EXCEEDS 220*. THIS IS ONLY A WARNING! ENGINE ERRLId □VER TEMP

Open the catalog to page 24

DIGITAL SCREEN WILL FLASH RED EVERY 2 SEC. WHEN THE FLUID COUPLER TEMP EXCEEDS180*F. THIS WILL SHUT OFF THE FLUID COUPLER AND IDLE THE ENGINE DOWN.

Open the catalog to page 25

ADVANCE OPTIONS SCREEN

Open the catalog to page 26

ADVANCED OPTIONS SCREEN Advanced Options ‘Color requires password Engine Faults Machine Info Advanced options screen is how to check engine fault code, service log, IO diagnostic inputs & outputs, machine setting, setting the RPM set points, setting the fan purge set points, machine performance

Open the catalog to page 27

Blue topics can be accessed by entering customer code 1,2,3,4,

Open the catalog to page 28

PLC PROGRAM MODE SCREEN. THIS SCREEN IS ONLY ACCESS WIT A FACTORY PRE SET PASSWORD / / _ K I * CONVEYOR LEFT/RIGHT TIER 4 ENGINE • I ) This set up screen allows you to configure your pic for any R Steel/Diamond Z product without the necessity of having to reprogram or inventory multiple pic’s.

Open the catalog to page 29

Engine Fault Code Screen This screen will show all active engine fault codes

Open the catalog to page 30

SELF DIAGNOSTIC SCREE THIS SCREEN WILL ALLOW YOU SEE ALL PLC ACTIVE FUNCTIONS AND POSSIBLE ACTIVE FAULTS INDICATING WHAT TYPE, ORIGIN AND DESTINATION.

Open the catalog to page 31

QDNVEyDR DOWN ENGINE IDLE DOWN ENGINE HILL ROLLER FLOAT COUPLER SAFETy HILL COUPLER ENGAGED This Input/Output screen is reached by selecting I/O diagnostics screen in the advanced options screen. With normal functionality when a sensor input is activated the corresponding light will lite green. If there is abnormal activity such as a dead short or over amp situation it will show yellow and scroll the fault code below.

Open the catalog to page 32

EXPANSION I/O SCREEN FOR TRACK MOUNTED UNITS TRHLH BRRHE TRHLH HLHRM Any active faults can be reset by turning off battery disconnect key for 30 seconds

Open the catalog to page 33

Iota Hours YOU CAN STORE JOB STATISTICS, DATE, RUN TIME

Open the catalog to page 34

Use the buttons down the right side to scroll through the data entry selections.

Open the catalog to page 35

Desired Engine Speed: 1550 RPM Oil Filter Differential Pressure: N/A ftercooler Coolant Pressure: N/A ftercooler Coolant Temperature: N/A Fuel Rate: 0.77 Gftt Fue Filter Differentia Pressure: N/A Intake Manifold 1 Pressure: 0.73 PSI ntake Mamfo d 2 Pressure: N/A Pre-Filter Fuel Pressure: N/A Primary Throttle Position: N/A econdary Throttle Position: N/A lurbocharger Inlet Temp: N/A

Open the catalog to page 36

FAN PURGE CONTROL SCREENS

Open the catalog to page 37

Water Temp Fuel Pressure Fan auto purge set at 200*. Plc will only allow one purge cycle every five Minutes to prevent over heating

Open the catalog to page 38

FAN PURGE SET POINT ONE = 10 MINUTES FOR EXTREMELY DRY OR DUSTY CONDITIONS.

Open the catalog to page 39

Fan purge set point TWO = 20 minutes For normal conditions.

Open the catalog to page 40

Fan purge time set point Three = 40 minutes For cooler conditions and where debris in the minimal

Open the catalog to page 41All Diamond Z catalogs and technical brochures

-

DZH3000 Series Grinders

2 Pages

-

FULL LINE PRODUCT CATALOG

8 Pages

-

DZC8048T Series Conveyor

2 Pages

-

DZT621 Series Trommel

3 Pages

-

dzh7000e

2 Pages

-

DZC8048

2 Pages

-

DZT621

13 Pages

-

DZH7000 Series

2 Pages