Catalog excerpts

welcome to di-soricabout the inventor of the fork light barrier: di-soric. For over 35 years, we have been producing and selling sensors used in industrial automation, primarily in assembly and handling technology, the automotive electronics and pharmaceutical industries and packaging technology. Other cornerstones of our product range are image processing and identification systems, high-quality LED lighting and products for work safety. Our subsidiary, di-soric Solutions GmbH & Co. KG, specializes in the business areas of image processing and identification. What sets us apart: In...

Open the catalog to page 2

di-soric facts ■ 100% owner-managed ■ headquarters Urbach, Germany ■ technology and production center Ludenscheid, Germany ■ representatives and branch offices in more than 40 countries ■ certifications IQNet, DQS - ISO 9001:2015, UL, RoHS, GS1

Open the catalog to page 3

solutions. clever. practical. solutions. To us, finding solutions means providing you with exactly the right solution for the job. ■ Solution-oriented consultation and implementation ■ Product portfolio for numerous application areas ■ Engineered solutions for industrial image processing

Open the catalog to page 4

CLEVER. To us, being clever means finding new, smart, unconventional and therefore more effective solutions. ¡¡ dded value for product and application A ¡¡ Efficient in function and application ¡¡ penness and flexibility for the best solutions O PRACTICAL. To us, being practical means being available, taking a straightforward approach and communicating as partners. ¡¡ olution-oriented consultation and technical expertise S ¡¡ traightforward, cooperative and dynamic approach S ¡¡ Address what is important and forget about unnecessary

Open the catalog to page 5

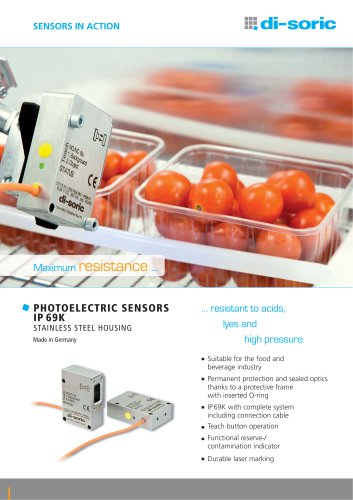

SERVICE AREAS QUALITY CONTROL Precision is the top priority in automated assembly and handling processes. Our sensors are ideal for checking the alignment and position of small, fast-moving parts that are difficult to detect. Each process must be carried out precisely and reliably to ensure that the quality of a finished product complies with its specifications. In addition, assembly is fast and simple and the sensors are very to configure and extremely durable. When combined with engineered solutions, our vision sensors and systems, color sensors and high-quality LED lighting systems...

Open the catalog to page 6

CONTENTS CREATING LABELS Roller diameter check Loop control system Punching and identifying labels DISPENSING LABELS Identifying and positioning labels Label sensors Detecting empty label coil Detecting end position at guide roller Triggering labeling CHECKING LABELING Position check for label fit Reading and verifying plain text Checking cover color

Open the catalog to page 7

LABELING TECHNOLOGY CREATING LABELS Roller diameter check Ultrasonic sensor FOR PRECISION AND MAXIMUM PRODUCTIVITY. The large number of applications and label types requires specific manufacturing methods. In order to optimally equip the various process steps and machine types, di-soric provides a range of sensors for printing, coating and laminating as well as for punching labels. Through simple adjustment, our sensors make it easy to achieve fast, process-reliable and flexible production of varying products and batch sizes. ¡¡ Measuring range 80 – 800 mm ¡¡ Measurement regardless of...

Open the catalog to page 8

Loop control system Punching and identifying labels Optical distance sensor Ultrasonic fork sensor Optical label sensor ¡¡ Red-light laser for easy alignment ¡¡ Analog current/voltage output, up to 2 switching outputs ¡¡ 4-digit display for indicating measured values and parameter settings ¡¡ Measurement virtually unaffected by surface ¡¡ Robust metal housing and resistant glass front window ¡¡ Compact ultrasonic edge sensor ¡¡ Visible area ±4 mm ¡¡ Insensitive to contamination with dust ¡¡ Sensing acoustically non-transmissive materials such as paper, plastic and metal foil regardless of...

Open the catalog to page 9

LABELING TECHNOLOGY DISPENSING LABELS DISPENSING A WIDE VARIETY OF LABELS WITH SPEED, PRECISION AND FLEXIBILITY. The number of labels processed on the market is steadily increasing. The spectrum ranges from transparent labels for the non-label look to printed and partially metallic labels and even thick booklets with integrated instruction leaflet. di-soric label sensors are equipped with auto-teach. The ideal switching point can be determined with the press of a button while the label tape is moving through the label sensor. This way, the auto-teach feature allows for extremely fast label...

Open the catalog to page 10

Optical label sensor Capacitive label sensor Ultrasonic label sensor ■ Auto-teach with operating button ■ Detection of paper and non-transparent labels ■ For processing thin to thick booklets with integrated instruction leaflet ■ Highest dispenser precision makes optimum labeling possible ■ The flat side enables installation at the label dispensing edge ■ Also for wide labels with fork depths up to 100 mm (OGUTI 005/1000) ■ Auto-teach with operating button ■ Detection of thin foil labels, transparent labels and paper labels ■ High process and long-term stability thanks to optimal...

Open the catalog to page 11

LABELING TECHNOLOGY DISPENSING LABELS Labeling: Non-transparent Labeling: Non-transparent Labeling: Transparent Labeling: Metallic Labeling: Booklet Carrier material: Non-transparent Carrier material: Transparent Carrier material: Transparent Carrier material: Transparent / non-transparent Carrier material: Transparent / Non-transparent OPTICAL OGUTI CAPACITIVE KSSTI ULTRASONIC UGUTI Optical label sensors detect both thin and thick paper labels with outstanding speed and precision thanks to their large fork openings. They stand out for their extremely high dispensing precision and...

Open the catalog to page 12

Fork opening Fork depth ultrasonic label sensors uguti Fork opening Fork depth Switching output Belt speed Reproducibility Activation time Plug connection 1) 2 mm label and 2 mm gap 2) Depends on the label material and carrier material Fork opening Fork depth Switching output Belt speed Activation time Remote teach

Open the catalog to page 13All Di-soric catalogs and technical brochures

-

Product family series 30

12 Pages

-

Laser Distance sensors

12 Pages

-

ULTRASONIC SENSORS US

8 Pages

-

FORK LIGHT BARRIERS WITH IO-LINK

16 Pages

-

CATALOG 2017/18

220 Pages