Catalog excerpts

30 - 55.4 kW|40 - 75 hp at 2200 - 2600 rpm EU Stage IIIB / US EPA Tier 4 500 h oil change intervals and a mainte- der inline engine with cooled, external exhaust gas recirculation with and without turbocharging and optionally with and without charge air cooling. nance-free valve train result in low maintenance costs and increased machine availability. The extremely compact engine design Use of DVERT® oxidation catalyst and customer friendly accesoires reduce the installation costs and increase the number of applications. (DOC) enables maintenance-free operation under all application and ambient conditions. A DVERT® particulate filter (DPF) is available as an option. The engines come with a modular ex- haust aftertreatment system (EAT) configuration including the option of engine mounted systems. This simplifies machine integration for the OEM considerably and virtually means a drop-in solution. 100% power take-off at flywheel and front end and additional side PTO drive with up to 120 Nm for the mounting of up to two hydraulic pumps. The powerful Common Rail injection system and highly-efficient combustion process with cooled external exhaust gas recirculation ensure optimum engine performance at low fuel consumption and exhaust emissions. The DVERT®oxidation catalyst enables the engines to meet the requirements of the EU Stage IIIB and US EPA Tier 4. A variant without EAT is optionally Best cold starting performance even available for EU Stage III A, US EPA Tier 4i and for less regulated markets. under extreme conditions. Technical data Engine type No. of cylinders Bore/stroke Displacement Max. nominal speed Engine type Power output as per ISO 143961) at speed Max. torque at speed Minimum idling speed Specific fuel consumption2) Weight as per DIN 70020 Part 7A3) kW | hp min-1 | rpm Nm | lb/ft min-1 | rpm min-1 | rpm g/kWh | lb/hph kg | lb 1) Power data without deduction of fan power. 2) Best full load consumption refers to diesel with a density of 0.835 kg/dm3 at 15°C | 6.96 lb/US gallon at 60°F. 3) Without starter/alternator, cooler and fluids but with flywheel and flywheel housing. The data on this data sheet are for information purposes only and are not binding values. The data in the quotation is definitive.

Open the catalog to page 1

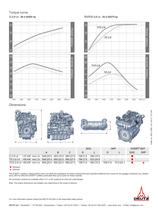

Torque curve TD/TCD 2.9 L4 - 55.4 kW|75 hp POWER (kW/hp) POWER (kW/hp) TORQUE (Nm/lb-ft) TORQUE (Nm/lb-ft) Standard Optional The DVERT® oxidation catalyst (DOC) does not satisfy the regulations of certain markets that have specified additional limit values for the number of particles (e.g. Switzerland). DEUTZ offers the DVERT® wallflow particulate filter as an option for these markets. All connection variants are available either in 0° or 90° positions for inlet and outlet flanges. Note: The engine dimensions and weights vary depending on the scope of delivery. For more information please...

Open the catalog to page 2All DEUTZ catalogs and technical brochures

-

DEUTZ TCD 12.0/16.0 2022

2 Pages

-

BFM 1013

2 Pages

-

DEUTZ TCD 18.0

2 Pages

-

DEUTZ TCD 9.0/12.0/13.5

2 Pages

-

TCD 2012

2 Pages

-

DEUTZ TCD 12.0/16.0 2020

2 Pages

-

TTCD 7.8 L6

2 Pages

-

DEUTZ TCD 7.8

2 Pages

-

DEUTZ TCD 4.1/6.1

2 Pages

-

DEUTZ TCD 3.6

2 Pages

-

TCD 2011

4 Pages

-

DEUTZ TCD 2.9

2 Pages

-

2012 The Genset Engine

2 Pages

-

DEUTZ TCD 2.2

2 Pages

-

DEUTZ G 2.2 - 2.9

2 Pages

-

FL 912

2 Pages

-

TCD 2015M

2 Pages

-

D 2011L

2 Pages

-

D 2011Li

2 Pages

-

2015M

2 Pages

-

TCG 2015

2 Pages

-

TCD 914M

2 Pages

-

DEUTZ Hybrid Drive

2 Pages

-

BFM 2011

2 Pages

-

TCD 2013

2 Pages

-

BFM 1015

2 Pages

-

BFL 914

4 Pages

-

912 The marine engine

4 Pages

-

2015M The marine engine

8 Pages

-

TCD 2013 The genset engine

4 Pages

-

L 2011 The genset engine

2 Pages

-

Flyer Oil Filter

2 Pages

-

Genuine DEUTZ pistons

2 Pages

-

Xchange engines and parts

9 Pages

-

1013M The marine engine

8 Pages

-

1015M The marine engine

8 Pages

-

1015 The genset engine

2 Pages

-

1013 The genset engine

2 Pages

-

M 2011 The genset engine

2 Pages

-

914 The genset engine

2 Pages

-

912 The genset engine

2 Pages