Catalog excerpts

ROTATING UNIONS water steam air hydraulic hot oil vacuum coolant custom applications

Open the catalog to page 1

Our aim: “To make every effort toward producing the best product of its kind on the Market”. This tenet serves as an incentive and an obligation in equal measure. Adherence to this policy has been responsible for our growth from a small garage shop to the world’s largest manufacturer of Rotating Unions with a world-wide sales and service network. Wherever water, steam, oil, coolant lubricants or other media have to be conveyed into or through turning machine parts, like rollers, shafts or spindles, rotating unions are employed in a wide range of industrial fields. DEUBLIN has its Corporate...

Open the catalog to page 2

Selection Chart for DEUBLIN Rotating Unions Max. Operating Data Size Special Features 3,500 bearings lubricated for life 3,500 general purpose, standard 1,500 general purpose with flange rotor 750 general purpose, standard 500 standard with thread or flange rotor 750 with repair cartridge 750 carbon graphite bearing and spherical seal 750 carbon graphite bearing and spherical seal 400 carbon graphite bearing and spherical seal 180 double carbon graphite bearing and spherical seal 350 double carbon graphite bearing and spherical seal 1,500 self-supported or in-the-shaft mounted 3,500 for...

Open the catalog to page 3

Sealing Original rotating unions used the media pressure to maintain seal contact. Logic indicates that as pressure increases, so do the forces holding the seals together - more pressure = tighter, better sealing. This is why they were called “pressure joints”. However, more pressure on the rotating seal face also meant more friction, higher torque and more wear. The resulting service life was not satisfactory. DEUBLIN was aware of the disadvantage and applied “Balanced Mechanical Seal Technology”, a decisive improvement. This simply means the load or pressure on the seal faces is kept to a...

Open the catalog to page 4

DEUBLIN Main Catalogue Reliability Years of experience, constant dialogues with customers, inhouse and supplier innovations have enabled DEUBLIN to offer reliable rotating unions at the cutting edge of technology. The right seal combination compatible to the media guarantees the maximum service life for every particular application. A clean and efficient warehousing and handling of the union is just as much a prerequisite for our customers as the adherence to the DEUBLIN specifications. The market demands more products with a longer service life at more extreme parameters. Besides new...

Open the catalog to page 5

DEUBLIN Main Catalogue DEUBLIN Rotating Unions 57 Series with Silicon Carbide Seals for Water Service, DN 10 - 50 - Operating Data Max. Water Pressure Max. Speed, Rotor with Straight Threads: Model monoflow and duoflow design self-supported rotating union radial housing connection balanced mechanical seal pinned rotor seal easy and quick replacement of sealing components (rotor seal, floating seal) ball bearings lubricated for life for poor water quality 3 vent holes forged brass housing stainless steel rotor special options: threaded vent holes, bearings splash proof, nickel-plated versions...

Open the catalog to page 6

DEUBLIN Main Catalogue DEUBLIN Rotating Unions 55 Series for General Purposes, DN 10 - 50 - monoflow and duoflow design self-supported rotating union radial housing connection balanced mechanical seal 3 vent holes forged brass housing stainless steel rotor special options: threaded vent holes, splash-proof bearings, nickel-plated and/or low torque design - Lubrication Guide page 52 Operating Data Max. Water Pressure Model 55 -555 Max. Water Pressure Model 655 Max. Saturated Steam Pressure (Intermittent) Max. Hot Oil Pressure Max. Speed, Rotors with Straight Threads: Model 55 -255 355 525 -555...

Open the catalog to page 7

DEUBLIN Main Catalogue 57 and 55 Series - Monoflow Rotating Unions DN 10 - 50 Monoflow unions are used when supply and return lines are connected to opposite sides of the cylinder or roll. Pilot Type Rotor ** DN 10 - 20 = hexagon DN 25 - 50 = two wrench flats (Basic Models) Model 55 STD

Open the catalog to page 8

DEUBLIN Main Catalogue Duoflow Supply Pipe Installations DEUBLIN water service unions can be adapted for Duoflow applications where a single media is circulated through and around the supply pipe. Duoflow elbows are available in 3 styles to accept a variety of different supply systems. The guidelines shown below should be carefully considered. A poorly designed supply system can contribute to premature union failure. Adapter* Where long pipes or high speeds are required, an adapter should be used to avoid transmitting stresses from heavy pipes, cascading water or vibrations to the union. A...

Open the catalog to page 9

DEUBLIN Main Catalogue 57 and 55 Series – Elbows DN 10 - 50 for Fixed, Threaded Supply Pipe Duoflow unions are used when supply and return lines are connected to one side of the cylinder or roll; non-supported pipe lengths no longer than 4 x D2; max. speed 1,000 RPM; for higher speeds divided supply pipes must be used. For rotating unions with pilot rotor, additional basic models and weight refer to page 8. Pipe supplied by customer ** DN 10 - 20 = hexagon DN 25 - 50 = two wrench flats

Open the catalog to page 10

DEUBLIN Main Catalogue 57 and 55 Series – Elbows DN 10 - 50 for Rotating Supply Pipe Duoflow unions are used when supply and return lines are connected to one side of the cylinder or roll; max. speed 1,000 RPM; for higher speeds divided supply pipes must be used. For rotating unions with pilot rotor, additional basic models and weight refer to page 8. DUO Pipe supplied by customer ** DN 10 - 20 = hexagon DN 25 - 50 = two wrench flats 57 and 55 Series – Elbows DN 10 - 50 with Divided Siphon Pipe (soldered) Duoflow unions are used when supply and return lines are connected to one side of the...

Open the catalog to page 11

DEUBLIN Main Catalogue DEUBLIN Rotating Union with Flange Rotor, DN 40, 50 and 65 - monoflow and duoflow design self-supported rotating union radial housing connection 3 or 4 vent holes forged brass housing (DN 40 and 50) and cast iron housing (DN 65) - steel rotor - Lubrication Guide page 52 Balanced mechanical seal: - Standard: Carbon Graphite/Bronze or Carbon Graphite/Ceramic - E.L.S. (Extended Life Sealing): Tungsten Carbide/Ceramic Operating Data Max. Water Pressure Model 555 655 ,755 Max. Satur. Steam Pressure (Interm.) Max. Speed Model 555 655 -755 Max. Temperature For further...

Open the catalog to page 12All DEUBLIN COMPANY catalogs and technical brochures

-

Combo

2 Pages

-

SRT-25

1 Pages

-

BC-54205 & BC-54206 SERIES

4 Pages

-

BC-54000 SERIES HOT OIL

4 Pages

-

BC-54065 SERIES

4 Pages

-

BC-54100 SERIES HOT OIL

4 Pages

-

BC-54100 SERIES

4 Pages

-

BC-54165 SERIES

4 Pages

-

SRD-40

1 Pages

-

SRD-3

1 Pages

-

SRC-4

1 Pages

-

SRC-30

1 Pages

-

SR0120

1 Pages

-

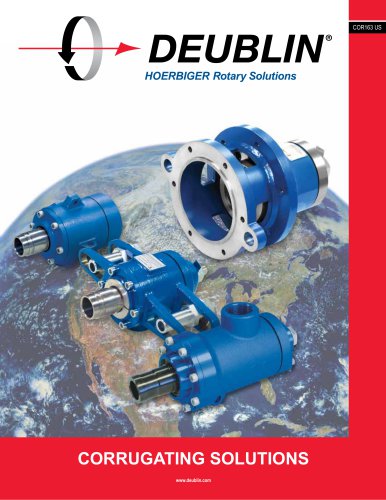

CORRUGATING SOLUTIONS

8 Pages

-

Steel

12 Pages

-

SpindleShield™ Alert System

4 Pages

-

Electrical slip rings

1 Pages

-

design Slip Rings

1 Pages

-

Duoflow Fixed Siphon

32 Pages

-

Electrical Slip Rings

6 Pages

-

InSight - Info

28 Pages