Catalog excerpts

Virtually maintenance-free elimination of Volatile Organic Compounds in exhaust gasses Despatch’s VOC Thermal Oxidizer was designed to eliminate over 99% of Volatile Organic Compounds (VOCs) from gasses exhausted during the drying step of solar cell manufacturing. The solar cell manufacturing process creates unwanted environmental pollutants which are byproducts of the drying process, and contain the non metallic ingredients found in the paste material such as ethanol, Texanol™ and terpineol. These pollutants can condense inside facility ductwork and create hazardous conditions. Destroying the VOCs using the Oxidizer eliminates the need to collect and dispose of this waste in a separate process. The exhaust exiting from the VOC Thermal Oxidizer contains only small amounts of CO2 and water vapor. In industries that emit VOCs and have established pollution control technology criteria, Thermal Oxidizers satisfy Best Available Control Technology (BACT) and Lowest Achievable Emission Rate (LAER). Designed for high-speed, high-capacity solar cell manufacturing lines Eliminates VOCs as close to the point of origin as possible Electric (no need for gas or open flame, no NOx generation) Runs off of furnace power (with soft-start software) Best in class (99% or better) destruction of VOCs: – Odors – 100% elimination of odor – 9%+ destruction of particulate matter 9 and VOCs (Volatile Organic Compounds) Exhaust contains only CO2 and water vapor Meets legal requirements regarding the capture or destruction of VOCs including TA Luft regulation of Germany Eliminates need for handling and disposal of waste product collected in VOC condensers Fits on top of CDF dryer - no additional footprint required Patent pending The operation of the VOC Thermal Oxidizer is based on the principle of combustion which is the most commonly used method to control emissions of organic compounds and is used in a variety of industries. Combustion systems are simple and have very high destruction efficiency. The VOC Thermal oxidizer maintains a temperature of 760°C (1400°F) to ensure destruction of all VOCs. The oxidation process releases heat and thereby contributes to maintaining the temperature of the oxidizer. Minneapolis • Shanghai • Berlin • Singapore • hsinchu

Open the catalog to page 1

Despatch's Thermal Oxidizer attaches Other VOC abatement options are ineffective and require extensive directly to the furnace, removing r^O, any chance of condensation. VOCs are incinerated, releasing only small Thermally managed Directly coupled maintenance. Condensers require containment and removal of hazardous solvents and regular cleaning. With remote facility abatement systems, solvents condense in the ductwork requiring extensive cleaning and creating a fire hazard. (~^<~>\/~ Facility ductwork r~VOC condenser (Requires regular (Condensation risk without thermal j-ijjLj...

Open the catalog to page 2All Despatch Industries catalogs and technical brochures

-

PWE Walk-In Ovens

2 Pages

-

PN Inert Atmosphere Ovens

2 Pages

-

RFF Class A Furnace

2 Pages

-

RBC

2 Pages

-

QMAX

2 Pages

-

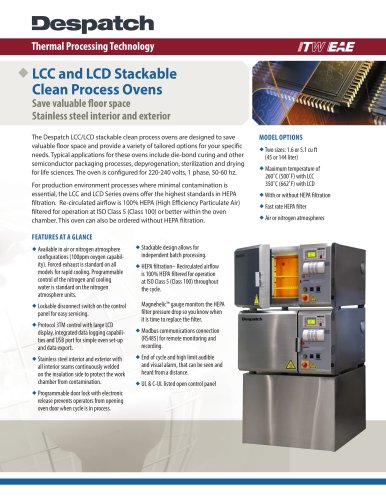

LCC AND LCD

2 Pages

-

LFC Class A

2 Pages

-

RAD/RFD1-42

2 Pages

-

LBB forced convection oven

2 Pages

-

LAC high-Performance oven

2 Pages

-

voc oxidizer

2 Pages

-

safire

2 Pages

-

dritech

2 Pages

-

CFSeriesSinglelane

2 Pages

-

RAF-Spec

2 Pages

-

Solar Brochure

12 Pages

-

Corporate Capabilities Brochure

20 Pages

-

Composite Curing Systems

8 Pages

-

ACER TECH TM

1 Pages

-

CFR - Carbon Fiber Research

2 Pages

-

Integrated Carbon Fiber Line

2 Pages

-

Carbon Fiber Oxidation Oven

2 Pages

-

Materials Brochure

4 Pages

-

Carbon Fiber Brochure

12 Pages

Archived catalogs

-

Standard Products Brochure

12 Pages

-

Batch Oven Selection Guide

7 Pages

-

Healthcare Brochure

4 Pages

-

Electronics Brochure

4 Pages