Catalog excerpts

u SaretM firing furnace with dritechtM dryer the tools you need for process perfection The SafireTM is built on the foundation of process separation, stability, high uptime and the ability to tailor thermal profiles around advanced materials and architectures. Safire ensures the greatest degree of firing repeatability and capability for cell efficiency optimization in a high capacity platform. The high performance Safire firing furnace has segmented and optimized critical components of the cell process for maximum control and stability. The Safire integrated with the DriTechTM dryer decouples VOC removal from the burn-out process and ensures that VOCs are removed to prevent furnace and facility contamination. Burn-out is separated from firing for proper binder removal, a contamination-free firing zone and a stable, repeatable thermal experience. The Safire’s twin chamber design eliminates lane-to-lane loading influence. The Safire offers further process optimization through MicrozoneTM Technology. Microzone Technology provides the ability to precisely tailor the burn-out interval, the time above melting temperature and the peak firing and cooling profiles. The advanced features and technology designed into the integrated Safire and DriTech firing and drying system offer a complete solution capable of achieving process perfection with all materials and architectures. Uniform, stable and repeatable cavity temperature (+/- 2°C) Dual independent chambers with no lane to lane influences Exact profile repeatability Soft start with reduced connected load Uninterruptible power supply Rapid thermal ramping (up to 250°C/sec) Enhanced thermal cooling (up to 160°C/sec) Up to 762 cm/min belt speed Edge contact belt Precise control for advanced cell metrics Enhanced MicrozoneTM Technology Enhanced SolectFireTM Technology Master production control interface Data logging and data trending DriTechTM Dryer with integrated VOC Thermal Oxidizer Hot swappable lamps on furnace 99% uptime (highest in the industry)

Open the catalog to page 1

SAFIRE with dritech PRODUCT CONFIGURATION Overall length Profiling systems Width at widest point Height to top of thermal oxidizer Standard entrance/exit table Open inspection area Conveyor type Lightweight balance spiral weave, NiCr V Material, friction drive with stand-offs Conveyor height above floor Lane-to-lane pitch SAFIRE Firing DriTech Dryer Overall length Overall width Overall height (without oxidizer) Connected load Typical operating load Typical flow Pressure (maximum) Recommended inlet temperature Process exhaust Cabinet exhaust Maximum temperature Conveyor speed range Conveyor...

Open the catalog to page 2All Despatch Industries catalogs and technical brochures

-

PWE Walk-In Ovens

2 Pages

-

PN Inert Atmosphere Ovens

2 Pages

-

RFF Class A Furnace

2 Pages

-

RBC

2 Pages

-

QMAX

2 Pages

-

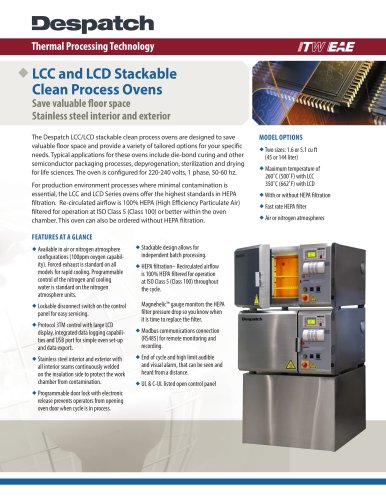

LCC AND LCD

2 Pages

-

LFC Class A

2 Pages

-

RAD/RFD1-42

2 Pages

-

LBB forced convection oven

2 Pages

-

LAC high-Performance oven

2 Pages

-

voc oxidizer

2 Pages

-

dritech

2 Pages

-

CFSeriesSinglelane

2 Pages

-

RAF-Spec

2 Pages

-

Solar Brochure

12 Pages

-

Corporate Capabilities Brochure

20 Pages

-

Composite Curing Systems

8 Pages

-

ACER TECH TM

1 Pages

-

CFR - Carbon Fiber Research

2 Pages

-

Integrated Carbon Fiber Line

2 Pages

-

Carbon Fiber Oxidation Oven

2 Pages

-

Materials Brochure

4 Pages

-

Carbon Fiber Brochure

12 Pages

Archived catalogs

-

VOC Thermal Oxidizer

2 Pages

-

Standard Products Brochure

12 Pages

-

Batch Oven Selection Guide

7 Pages

-

Healthcare Brochure

4 Pages

-

Electronics Brochure

4 Pages