Catalog excerpts

♦ PWE Walk-In Ovens Designed for High Temperature Industrial Process Versatility and Dependability The PWE is designed for high temperature industrial process versatility and dependability. Typical applications include aging, bonding, curing and heat treating. They feature horizontal recirculating airflow to ensure superior temperature uniformity and process reliability. The PWE is great for higher temperature custom and modified applications with a max temperature of 454°C (850°F). It can be used in Class A applications that include flammable solvents or large amounts of moisture removal. It is specifically designed to meet NFPA 86 requirements and includes a pressure relief panel, purge timer and exhaust fan. The PWE Walk-in oven uses horizontal recirculating airflow to ensure uniform temperatures throughout the oven. A high-volume fan circulates air through perforated, aluminized steel walls to create a constant horizontal airflow across all sections of the oven. Each oven is shipped fully assembled and wired to minimize installation time. Once the oven is in place, simply make the electrical power connections and turn it on. FEATURES AT A GLANCE ♦ Temperatures up to 454°C (850°F) ♦ 104 or 216 cubic feet (2945 or 6116 liters) ♦ Class A for handling flammable solvents ♦ Fully assembled and factory tested ♦ Protocol 3™ control with large LCD display, integrated data logging capabilities and USB port for simple oven set-up and data export. ♦ Aluminized steel interior ♦ High volume recirculating fan provides faster, more uniform heating - saving process time and improving product quality ♦ Insulated floor with truck tracks ♦ UL and C-UL listed open industrial control panel

Open the catalog to page 1

♦ Forced exhaust to aid in cool-down or handling of large amounts of moisture ♦ Alternate controller for controlling rate of temperature rise. Can also be used for process timing functions ♦ Door switch to shut down the heater and blower when door is open ♦ Loading trucks and shelves ♦ Access ports for test wires ♦ Proportioning gas fired heater ♦ Chart recorder ♦ Audible alarm ♦ Process timers to automatically shut down oven at end of process Notes: Minimum operating temperature and cooling times are based on 20°C ambient temperature measured at the fresh air inlet with the fresh air and...

Open the catalog to page 2All Despatch Industries catalogs and technical brochures

-

PN Inert Atmosphere Ovens

2 Pages

-

RFF Class A Furnace

2 Pages

-

RBC

2 Pages

-

QMAX

2 Pages

-

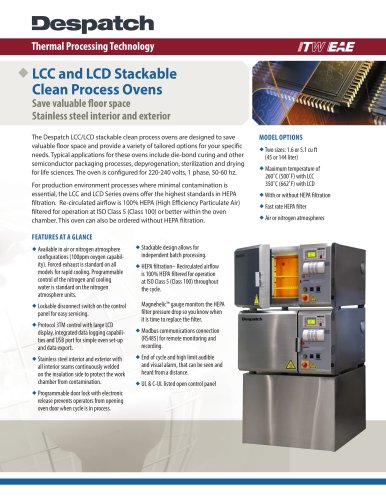

LCC AND LCD

2 Pages

-

LFC Class A

2 Pages

-

RAD/RFD1-42

2 Pages

-

LBB forced convection oven

2 Pages

-

LAC high-Performance oven

2 Pages

-

voc oxidizer

2 Pages

-

safire

2 Pages

-

dritech

2 Pages

-

CFSeriesSinglelane

2 Pages

-

RAF-Spec

2 Pages

-

Solar Brochure

12 Pages

-

Corporate Capabilities Brochure

20 Pages

-

Composite Curing Systems

8 Pages

-

ACER TECH TM

1 Pages

-

CFR - Carbon Fiber Research

2 Pages

-

Integrated Carbon Fiber Line

2 Pages

-

Carbon Fiber Oxidation Oven

2 Pages

-

Materials Brochure

4 Pages

-

Carbon Fiber Brochure

12 Pages

Archived catalogs

-

VOC Thermal Oxidizer

2 Pages

-

Standard Products Brochure

12 Pages

-

Batch Oven Selection Guide

7 Pages

-

Healthcare Brochure

4 Pages

-

Electronics Brochure

4 Pages