Catalog excerpts

The PN Series Inert Atmosphere Ovens are designed to accommodate a wide variety of processes where an inert atmosphere is required to prevent product oxidation. Typical applications include curing, bonding and heat treating. The PN Series contains a digital PID controller that is easy to use and configure saving the operator time. It comes with two temperature ranges and two sizes to meet your process needs. The stainless steel, continuously welded interior is ideal for highly corrosive conditions or where interior cleanliness is critical. It has adjustable recirculating air louvers that allow "fine tuning" to assure uniform airflow, even with varying load configurations and consistent product heating. It also has a heat exchanger for providing rapid cool-down or the ability to operate at low temperatures within a sealed chamber - Air-to-water is used on 343°C models, air-to-air for 538°C models. Despatch provides the design integrity, manufacturing experience and emphasis on quality necessary for dependable operation and excellent process control. FEATURES AT A GLANCE ♦ Horizontal airflow for superior temperature uniformity ♦ Two maximum temperature ratings: 343°C (650°F) and 538°C (1000°F) ♦ 9 cubic feet (255 liters) ♦ Inert atmosphere capability ♦ Heat exchanger for rapid cool down ♦ Digital, easy to use, PID control ♦ Stainless Steel interior ♦ Adjustable recirculating air louvers assure uniform airflow ♦ Chamber pressure gauge ♦ Positive sealing door for atmosphere integrity ♦ UL and C-UL listed open industrial control panel

Open the catalog to page 1

♦ Programmable controls for controlling rate of temperature rise and process timing functions. ♦ Recorders - 10 inch diameter round chart. Strip charts also available. ♦ Oxygen concentration management system to guarantee low oxygen concentrations and prevent heating until desired oxygen level is achieved, assuring optimal product results. ♦ Process timers to automatically shut down oven at end of process. ♦ Alarms, audible and visual to signal end of process or other events. ♦ Disconnect switch in control panel to completely disconnect power to equipment. Disconnect switch must be opened...

Open the catalog to page 2All Despatch Industries catalogs and technical brochures

-

PWE Walk-In Ovens

2 Pages

-

RFF Class A Furnace

2 Pages

-

RBC

2 Pages

-

QMAX

2 Pages

-

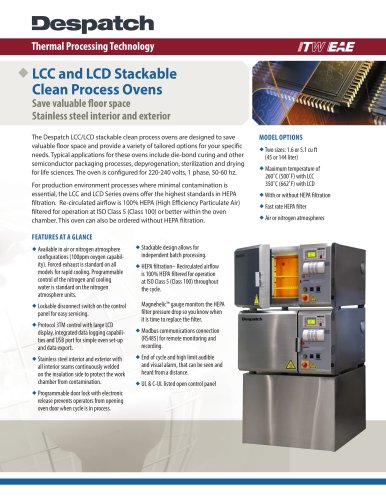

LCC AND LCD

2 Pages

-

LFC Class A

2 Pages

-

RAD/RFD1-42

2 Pages

-

LBB forced convection oven

2 Pages

-

LAC high-Performance oven

2 Pages

-

voc oxidizer

2 Pages

-

safire

2 Pages

-

dritech

2 Pages

-

CFSeriesSinglelane

2 Pages

-

RAF-Spec

2 Pages

-

Solar Brochure

12 Pages

-

Corporate Capabilities Brochure

20 Pages

-

Composite Curing Systems

8 Pages

-

ACER TECH TM

1 Pages

-

CFR - Carbon Fiber Research

2 Pages

-

Integrated Carbon Fiber Line

2 Pages

-

Carbon Fiber Oxidation Oven

2 Pages

-

Materials Brochure

4 Pages

-

Carbon Fiber Brochure

12 Pages

Archived catalogs

-

VOC Thermal Oxidizer

2 Pages

-

Standard Products Brochure

12 Pages

-

Batch Oven Selection Guide

7 Pages

-

Healthcare Brochure

4 Pages

-

Electronics Brochure

4 Pages