Catalog excerpts

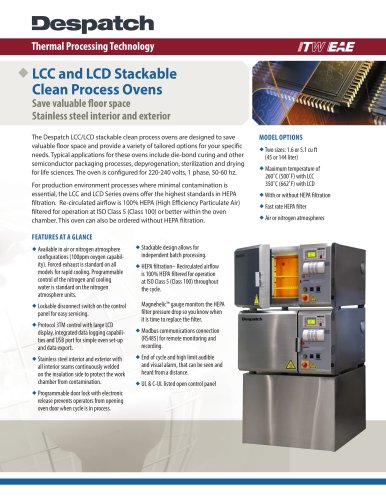

Thermal Processing Technology ♦ LCC and LCD Stackable Clean Process Ovens Save valuable floor space Stainless steel interior and exterior The Despatch LCC/LCD stackable clean process ovens are designed to save valuable floor space and provide a variety of tailored options for your specific needs. Typical applications for these ovens include die-bond curing and other semiconductor packaging processes, depyrogenation, sterilization and drying for life sciences. The oven is configured for 220-240 volts, 1 phase, 50-60 hz. For production environment processes where minimal contamination is essential, the LCC and LCD Series ovens offer the highest standards in HEPA filtration. Re-circulated airflow is 100% HEPA (High Efficiency Particulate Air) filtered for operation at ISO Class 5 (Class 100) or better within the oven chamber. This oven can also be ordered without HEPA filtration. MODEL OPTIONS ♦ Two sizes: 1.6 or 5.1 cu ft (45 or 144 liter) ♦ Maximum temperature of 260°C (500°F) with LCC 350°C (662°F) with LCD ♦ With or without HEPA filtration ♦ Fast rate HEPA filter ♦ Air or nitrogen atmospheres FEATURES AT A GLANCE ♦ Available in air or nitrogen atmosphere configurations (100ppm oxygen capability). Forced exhaust is standard on all models for rapid cooling. Programmable control of the nitrogen and cooling water is standard on the nitrogen atmosphere units. ♦ Lockable disconnect switch on the control panel for easy servicing. ♦ Protocol 3TM control with large LCD display, integrated data logging capabilities and USB port for simple oven set-up and data export. ♦ Stainless steel interior and exterior with all interior seams continuously welded on the insulation side to protect the work chamber from contamination. ♦ Programmable door lock with electronic release prevents operators from opening oven door when cycle is in process. ♦ Stackable design allows for independent batch processing. ♦ HEPA filtration- Recirculated airflow is 100% HEPA filtered for operation at ISO Class 5 (Class 100) throughout the cycle. Magnehelic™ gauge monitors the HEPA filter pressure drop so you know when it is time to replace the filter. ♦ Modbus communications connection (RS485) for remote monitoring and recording. ♦ End of cycle and high limit audible and visual alarm, that can be seen and heard from a distance. ♦ UL & C-UL listed open control panel

Open the catalog to page 1

OPTIONS ♦ Silicone-free construction ♦ Non-HEPA filtration model ♦ Fast rate-HEPA filter ♦ Nitrogen atmosphere ♦ Door interlock switch turns off heater and fan when door is opened ♦ Chart recorders ♦ Three color process stack light ♦ Skirted stands with leveling legs ♦ Extra shelves ♦ Data acquisition software ♦ 208 volt service ♦ CE compliance Warning: Despatch Stackable Clean Room Ovens are not to be used with flammable solvents, combustible materials or enclosed containers. If your process involves flammable solvents, consult factory about modifications. Specifications are subject to...

Open the catalog to page 2All Despatch Industries catalogs and technical brochures

-

PWE Walk-In Ovens

2 Pages

-

PN Inert Atmosphere Ovens

2 Pages

-

RFF Class A Furnace

2 Pages

-

RBC

2 Pages

-

QMAX

2 Pages

-

LFC Class A

2 Pages

-

RAD/RFD1-42

2 Pages

-

LBB forced convection oven

2 Pages

-

LAC high-Performance oven

2 Pages

-

voc oxidizer

2 Pages

-

safire

2 Pages

-

dritech

2 Pages

-

CFSeriesSinglelane

2 Pages

-

RAF-Spec

2 Pages

-

Solar Brochure

12 Pages

-

Corporate Capabilities Brochure

20 Pages

-

Composite Curing Systems

8 Pages

-

ACER TECH TM

1 Pages

-

CFR - Carbon Fiber Research

2 Pages

-

Integrated Carbon Fiber Line

2 Pages

-

Carbon Fiber Oxidation Oven

2 Pages

-

Materials Brochure

4 Pages

-

Carbon Fiber Brochure

12 Pages

Archived catalogs

-

VOC Thermal Oxidizer

2 Pages

-

Standard Products Brochure

12 Pages

-

Batch Oven Selection Guide

7 Pages

-

Healthcare Brochure

4 Pages

-

Electronics Brochure

4 Pages