Catalog excerpts

INSPIRED INNOVATION INDUSTRIAL Oven Selection Guide A guide to selecting the right oven for your processing application

Open the catalog to page 1

a guide to selecting the right oven for your processing application 1. What is your Application? The possibilities are virtually limitless, from the common to the out-of-the-ordinary. Some applications include: Batch Ovens Finish u Sterilization/Depyrogenation u Laboratory Testing u Clean Process Production u Shrink Fitting Treating u Drying u Aging For applications where the load size or production volumes vary substantially, batch processing is a good approach. Batch ovens are also ideal for situations that require a high degree of flexibility in terms of process variables such as...

Open the catalog to page 2

Chamber size depends on the size of the product or parts, the number of products in each batch, and the number of batches required per day to meet production requirements. If the interior space is too small, insufficient space between parts results in poor performance. If it is too large, space, time and energy are wasted. When considering your application’s temperature requirements, first note the minimum and maximum operating temperatures required. Other temperature considerations include: When using gravity or forced circulating airflow, allow 2-3 inches (5.1 - 7.6cm) around each part...

Open the catalog to page 3

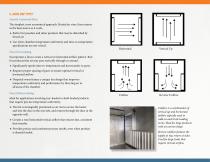

6. Airflow type? Gravity Convected Heat The simplest, most economical approach. Heated air rises, then returns to the heat source as it cools. u erfect P for powders and other products that may be disturbed by forced air. when chamber temperature uniformity and time-to-temperature specifications are not critical. Forced Circulating Reverse Uniflow Incorporates a fan to create a vertical or horizontal airflow pattern. Best for products that air may pass vertically through or around. u ignificantly S speeds time-to-temperature and heat transfer to parts. proper spacing of parts to ensure...

Open the catalog to page 4

7. design and construction quality? 8. Special processing needs? Proper Oven Construction: Flammable Materials - Class A Ovens temperature uniformity and performance u Reduces heat loss and energy expenses u Simplifies cleaning and service The National Fire Protection Association (NFPA) requires specially designed “Class A” ovens for processing products involving flammable solvents, volatiles or combustible materials. Oven Interior Class A Ovens Feature: Stainless steel provides excellent corrosion resistance and cleans easily. All Despatch interior oven surfaces are available in stainless...

Open the catalog to page 5

Custom Solutions 9. Temperature controller? Controllers play a key role in overall oven performance. Despatch uses microprocessor-based, digital proportioning controllers. Precise temperature control is achieved with a thermocouple sensor and solid state heater controls. u ingle S setpoint controllers are simplest to use and are appropriate when the process requires one setpoint temperature. ramp/soak controllers are appropriate when multiple setpoint temperatures are required, or when the rate of heating must be controlled. The Despatch Protocol 3TM controller can function either as a...

Open the catalog to page 6

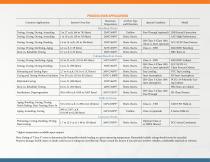

Process Oven Applications Common Applications Maximum Temperature Interior Oven Size Air Flow Type and Direction Special Condition Benchtop Ovens Testing, Curing, Drying, Annealing Testing, Curing, Drying, Annealing Horiz. Recirc. Testing, Curing, Drying, Bonding Horiz. Recirc. ISO Class 5 (Class 100) LCC/LCD Clean Process (Class A, Inert optional) Curing, Drying, Sterilizing, Aging Horiz. Recirc. Burn-in, Reliability Testing Horiz. Recirc. Pass Through (optional) LBB Forced Convection LAC High Performance RAD/RFD Benchtop RBC Burn-in Cabinet/Reach-In Ovens Curing, Drying, Sterilizing,...

Open the catalog to page 7

Service and Support: Global Presence, with Local Expertise Despatch provides expert technical service, a range of installation options and an extensive parts inventory to all of our customers worldwide. And, if that’s not enough, we have the capability to service some competitor’s equipment! At Despatch, we believe in exceeding customer expectations and going above and beyond what an average equipment manufacturer will provide. Worldwide service, installation, parts and advice – we have you covered! WE’RE HERE FOR YOU, WHENEVER, WHEREVER Rest assured that when you call our Service Help...

Open the catalog to page 8All Despatch Industries catalogs and technical brochures

-

PWE Walk-In Ovens

2 Pages

-

PN Inert Atmosphere Ovens

2 Pages

-

RFF Class A Furnace

2 Pages

-

RBC

2 Pages

-

QMAX

2 Pages

-

LCC AND LCD

2 Pages

-

LFC Class A

2 Pages

-

RAD/RFD1-42

2 Pages

-

LBB forced convection oven

2 Pages

-

LAC high-Performance oven

2 Pages

-

voc oxidizer

2 Pages

-

safire

2 Pages

-

dritech

2 Pages

-

CFSeriesSinglelane

2 Pages

-

RAF-Spec

2 Pages

-

Solar Brochure

12 Pages

-

Corporate Capabilities Brochure

20 Pages

-

Composite Curing Systems

8 Pages

-

ACER TECH TM

1 Pages

-

CFR - Carbon Fiber Research

2 Pages

-

Integrated Carbon Fiber Line

2 Pages

-

Carbon Fiber Oxidation Oven

2 Pages

-

Materials Brochure

4 Pages

-

Carbon Fiber Brochure

12 Pages

Archived catalogs

-

VOC Thermal Oxidizer

2 Pages

-

Standard Products Brochure

12 Pages

-

Batch Oven Selection Guide

7 Pages

-

Healthcare Brochure

4 Pages

-

Electronics Brochure

4 Pages