Catalog excerpts

INSPIRED INNOVATION Solution Heat Treat Furnace Designed for smaller components The horizontal solution heat treat furnace is used for heat treating smaller components and provides many of the features of more expensive drop bottom type furnaces. Installation effort required for this furnace is minimal. The furnace utilizes a powered roller conveyor system and a pneumatically operated quench elevator located directly in front of the furnace above the quench tank. The elevator is complete with guide columns and is shipped preassembled ready for immediate set-up. Air piping and interconnecting wiring from the furnace to the control cabinet must be accomplished in the field. The door is pneumatically clamped against the furnace front for a tight seal. Alternate instrumentation Basket design and construction Delivered ready for production Simple, touch-screen operator control Economical for small part or low production runs Easy to install Excellent uniformity (± 5°F) Automatic operation Quench tank agitation standard Quench tank heater Minneapolis • Shanghai • Berlin • Singapore • hsinchu • tokyo • seoul

Open the catalog to page 1

LOAD & UNLOAD POSITION QUENCH POSITION HEAT POSITION Quench time: 7 - 10 seconds Capacity, load weight: Maximum of 650lbs (including basket) Quench tank agitation: Propeller type mixer Maximum operating temperature: 593°C/1100°F Electricity: 480/3/60 Air: 100 PSIG Water: City Exhaust: None Operation The furnace is preheated. The operator loads the work basket onto the load and unload conveyor. When the operator pushes the cycle start button, the furnace door opens automatically and the work basket is conveyed across the quench elevator roller bed and into the furnace. The pre-programmed...

Open the catalog to page 2All Despatch Industries catalogs and technical brochures

-

PWE Walk-In Ovens

2 Pages

-

PN Inert Atmosphere Ovens

2 Pages

-

RFF Class A Furnace

2 Pages

-

RBC

2 Pages

-

QMAX

2 Pages

-

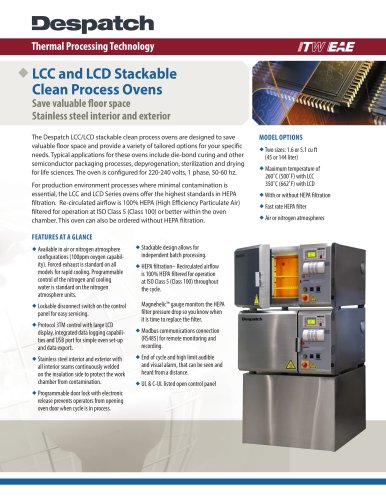

LCC AND LCD

2 Pages

-

LFC Class A

2 Pages

-

RAD/RFD1-42

2 Pages

-

LBB forced convection oven

2 Pages

-

LAC high-Performance oven

2 Pages

-

voc oxidizer

2 Pages

-

safire

2 Pages

-

dritech

2 Pages

-

CFSeriesSinglelane

2 Pages

-

RAF-Spec

2 Pages

-

Solar Brochure

12 Pages

-

Corporate Capabilities Brochure

20 Pages

-

Composite Curing Systems

8 Pages

-

ACER TECH TM

1 Pages

-

CFR - Carbon Fiber Research

2 Pages

-

Integrated Carbon Fiber Line

2 Pages

-

Carbon Fiber Oxidation Oven

2 Pages

-

Materials Brochure

4 Pages

-

Carbon Fiber Brochure

12 Pages

Archived catalogs

-

VOC Thermal Oxidizer

2 Pages

-

Standard Products Brochure

12 Pages

-

Batch Oven Selection Guide

7 Pages

-

Healthcare Brochure

4 Pages

-

Electronics Brochure

4 Pages