Catalog excerpts

DriTechTM Dryer A revolutionary new dryer for advanced drying of metallization pastes The new Despatch DriTechTM Dryer introduces a unique hybrid heating technology for the next generation in metallization drying performance. Handles difcult to dry pastes The dryer is designed to decouple the VOC removal and binder burn-off for a more efficient drying process. A centrally located point-of-generation thermal oxidizer provides maintenance-free VOC abatement ensuring that the chamber remains free of contaminates. Increased air dilution reduces the solvent concentration within the chamber and eliminates dead spots. Airflow is managed to reduce cold air entrainment at the entrance and exit. A rapid peak temperature and internal management of the insulation surface temperature minimizes condensation. Dries at fast belt speeds VOC Thermal Oxidizer abatement Decouples VOC removal and binder burn-off Integration with every major metallization printer line Smaller footprint Up to 760 cm/minute belt speed Mesh belt Uninterruptible power supply Safe, simple chamber accessibility The DriTechTM Dryer is designed for a fast peak thermal profile that delivers lower wafer exit temperature and maximum VOC release at an early stage resulting in maximum paste drying efficiency. The dryer has the flexibility to effectively dry a wide range of difficult to dry pastes. Patent pending

Open the catalog to page 1

DriTechTM Dryer SINGLE LANE DUAL LANE PRODUCT CONFIGURATION Overall length Overall width Height to top of thermal oxidizer 287.5 cm (113 in) 20 cm (7.8 in) Standard at belt with balanced spiral open weave, Nichrome V material, friction drive. 92 - 100 cm (36 - 39 in) Conveyor width Mesh style belt, Nichrome V material Conveyor height above oor Conveyor type (Options include standoffs as well as edge support) Wafer cooling (For 60°C wafer or less based on 508 cm/minute belt speed) Standard entrance/exit table Frame height (w/o oxidizer) Belt variations ELECTRICAL REQUIREMENTS Voltage...

Open the catalog to page 2All Despatch Industries catalogs and technical brochures

-

PWE Walk-In Ovens

2 Pages

-

PN Inert Atmosphere Ovens

2 Pages

-

RFF Class A Furnace

2 Pages

-

RBC

2 Pages

-

QMAX

2 Pages

-

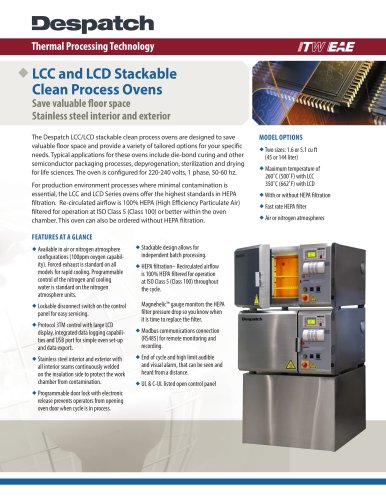

LCC AND LCD

2 Pages

-

LFC Class A

2 Pages

-

RAD/RFD1-42

2 Pages

-

LBB forced convection oven

2 Pages

-

LAC high-Performance oven

2 Pages

-

voc oxidizer

2 Pages

-

safire

2 Pages

-

CFSeriesSinglelane

2 Pages

-

RAF-Spec

2 Pages

-

Solar Brochure

12 Pages

-

Corporate Capabilities Brochure

20 Pages

-

Composite Curing Systems

8 Pages

-

ACER TECH TM

1 Pages

-

CFR - Carbon Fiber Research

2 Pages

-

Integrated Carbon Fiber Line

2 Pages

-

Carbon Fiber Oxidation Oven

2 Pages

-

Materials Brochure

4 Pages

-

Carbon Fiber Brochure

12 Pages

Archived catalogs

-

VOC Thermal Oxidizer

2 Pages

-

Standard Products Brochure

12 Pages

-

Batch Oven Selection Guide

7 Pages

-

Healthcare Brochure

4 Pages

-

Electronics Brochure

4 Pages