Catalog excerpts

Drying and Firing Furnaces The world’s best selling metallization furnace For highly efficient solar cells at the lowest possible cost, more solar manufacturers choose Despatch Firing Furnaces than any other brand. Rapid thermal ramping (up to 200°C/sec) The drying and firing system is easily integrated with every major metallization printer line and provides advanced technology to accomodate next generation pastes. Enhanced thermal cooling (up to 100°C/sec) The furnace is now available with SolectFireTM Technology. This critical advancement opens the process window and gives operators independent open and closed loop control of the top and bottom of each firing zone. This innovative decoupling technology provides greater thermal control and sets the stage for next generation pastes. Despatch CF-Series metallization furnaces are designed for high throughput, ease of maintenance, and consistent process repeatability ensuring consistently high yields and superior product quality. Patented push-button chamber access and optional VOC Thermal Oxidizers make maintenance easy. These innovations maximize performance and up time and result in lowest cost of ownership while producing the highest efficiency cells. Up to 300 ipm belt speed Uniform, stable and repeatable cavity temperature (+/- 2°C) Mesh belt with stand-offs Soft start with reduced connected load Enhanced software recipe management Advanced graphical user interface Master production control interface Data logging Redundant over-temperature shutdown Safe, simple chamber accessibility Eye-level electronics for easy maintainance Failed element monitor Uninterruptible power supply Integration to wafer automation equipment Patented technology New advanced thermal control

Open the catalog to page 1

CF-SL FIRING CDF-SL DRYING/FIRING Overall length SolectFireTM Technology Overall width Edge contact belt Overall height Standard entrance/exit table Open inspection area Conveyor type Lightweight balance spiral weave, Nichrome V material, friction drive with stand-offs Conveyor height above floor Conveyor width (custom configurations up to 24in/61cm wide available) PRODUCT CONFIGURATION Profiling systems VOC thermal oxidizer SECS/GEM CE compliance ELECTRICAL REQUIREMENTS Voltage Connected load Typical operating load Typical flow Pressure (maximum) Recommended inlet temperature Maximum...

Open the catalog to page 2All Despatch Industries catalogs and technical brochures

-

PWE Walk-In Ovens

2 Pages

-

PN Inert Atmosphere Ovens

2 Pages

-

RFF Class A Furnace

2 Pages

-

RBC

2 Pages

-

QMAX

2 Pages

-

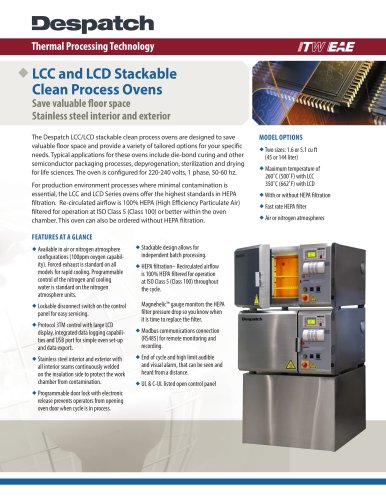

LCC AND LCD

2 Pages

-

LFC Class A

2 Pages

-

RAD/RFD1-42

2 Pages

-

LBB forced convection oven

2 Pages

-

LAC high-Performance oven

2 Pages

-

voc oxidizer

2 Pages

-

safire

2 Pages

-

dritech

2 Pages

-

RAF-Spec

2 Pages

-

Solar Brochure

12 Pages

-

Corporate Capabilities Brochure

20 Pages

-

Composite Curing Systems

8 Pages

-

ACER TECH TM

1 Pages

-

CFR - Carbon Fiber Research

2 Pages

-

Integrated Carbon Fiber Line

2 Pages

-

Carbon Fiber Oxidation Oven

2 Pages

-

Materials Brochure

4 Pages

-

Carbon Fiber Brochure

12 Pages

Archived catalogs

-

VOC Thermal Oxidizer

2 Pages

-

Standard Products Brochure

12 Pages

-

Batch Oven Selection Guide

7 Pages

-

Healthcare Brochure

4 Pages

-

Electronics Brochure

4 Pages