Catalog excerpts

INSPIREDINNOVATION PROESS AND TECHNOLOGY SOLUTIONS FOR CARBON FIBER PRODUCTION

Open the catalog to page 1

INSPIRED INNOVATION Despatch Industries has specialized in thermal processing for over 100 years and is actively using this technical expertise to provide innovative solutions to critical applications in a broad range of markets and cutting edge technology worldwide. Our innovations are inspired by our customers. Through collaboration in design and engineering, we observe how our technology can best be applied to your needs, giving you a unique competitive advantage. Despatch has three dedicated business groups to meet the demands of the rapidly expanding thermal, solar and carbon fiber...

Open the catalog to page 2

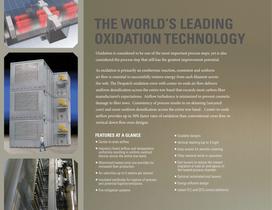

Oxidation is considered to be one of the most important process steps, yet is also considered the process step that still has the greatest improvement potential. As oxidation is primarily an exothermic reaction, consistent and uniform air flow is essential to successfully remove energy from each filament across the web. The Despatch oxidation oven with center-to-ends air flow delivers uniform densification across the entire tow band that exceeds most carbon fiber manufacturer's expectations. Airflow turbulence is minimized to prevent cosmetic damage to fiber tows. Consistency of process...

Open the catalog to page 4

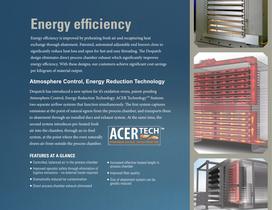

Energy efficiency Energy efficiency is improved by preheating fresh air and recapturing heat exchange through abatement. Patented, automated adjustable end louvers close to significantly reduce heat loss and open for fast and easy threading. The Despatch design eliminates direct process chamber exhaust which significantly improves energy efficiency. With these designs, our customers achieve significant cost savings per kilogram of material output. Atmosphre Control, Energy Rduction Technology Despatch has introduced a new option for it's oxidation ovens, patent-pending Atmosphere Control,...

Open the catalog to page 5

Intgration and optimizatio n of the small and large tow production lines Through our exprience and expertise in the carbon fiber industry, we have built connections and relationships that offer us the ability to facilitate the installation, set-up and optimization of a complete manufacturing line through one point of contact. Our team of experts from around the world has over 40 years of carbon fiber processing experience. Despatch provides integrated solutions for 1k to 320k tow manufacturing lines. We provide the equipment and optimize your processes for the highest quality fiber and...

Open the catalog to page 7

A complte carbon fiber production line in a micro-scale package SERIES CARBON FIBER RESEARCH equipment package ♦ Center-to-ends oxidations ovens ♦ Abatement Systems ♦I Input creel ♦I Rolls, stands and drives ♦ Pre-carbonization furnace ♦ Carbonization furnace ♦ Surface treatment equipment ♦ Sizing equipment ♦ Non-contact drying system ♦ Take-up winders ♦ Integrated control system with ♦ SCADA interface

Open the catalog to page 8

Carbon Fiber Research The Despatch CFR Sries is a complte carbon fiber production line in a micro-scale package. Designed for universities and laboratories the CFR Series allows you to study and test fibers and processes with the same quality of a full production line at a fraction of the cost. The CFR is available as a complete line or as independent pieces.The line includes the same quality equipment offered in our production scale lines at a smaller scale. Despatch offers world leading center-to-ends oxidation ovens, energy efficient LT and HT furnaces designed for ease of operation with...

Open the catalog to page 9

integr Line C JUII I IUUI stem Centralized Control of the Entire Production Line Through our exprience and expertise in carbon fiber Despatch offers an integrated control system for full production lines. This control System allows for accurate, centralized control of temperature and transport drive speeds, higher levels of automation, and increased flexibility. The integrated control system also includes full data-logging and trending and enables the line to run at peak performance with maximum production output. Fire Mitigation System A new Fire Mitigation System is now available. The...

Open the catalog to page 10

ERVICE Service and support: global prsence, with local expertise As an integrated solution provider Despatch is able to install, set up and optimize your complete carbon fiber line for peak performance. We provide expert technical service and an extensive parts inventory to all of our customers worldwide. Despatch is backed by over 100 years of experience in thermal process application along with a team of carbon fiber experts from around the world. At Despatch, we believe in exceeding customer expectations and going above and beyond what other equipment manufacturers provide. Worldwide...

Open the catalog to page 11

A unique comptitive advantage: Despatch Innovation Resources Despatch provides a unique opportunity for process and product development and valuation with a simple, singular focus: To provide customers with cost-effective solutions up front驗before equipment design begins or purchase commitments are made. Our clients enjoy direct access to highly skilled Despatch scientists and engineers who are experts at process optimization and helping customers solve complex problems. The Despatch Innovation Center is equipped with process tools needed for analysis and validation of equipment. This...

Open the catalog to page 12All Despatch Industries catalogs and technical brochures

-

PWE Walk-In Ovens

2 Pages

-

PN Inert Atmosphere Ovens

2 Pages

-

RFF Class A Furnace

2 Pages

-

RBC

2 Pages

-

QMAX

2 Pages

-

LCC AND LCD

2 Pages

-

LFC Class A

2 Pages

-

RAD/RFD1-42

2 Pages

-

LBB forced convection oven

2 Pages

-

LAC high-Performance oven

2 Pages

-

voc oxidizer

2 Pages

-

safire

2 Pages

-

dritech

2 Pages

-

CFSeriesSinglelane

2 Pages

-

RAF-Spec

2 Pages

-

Solar Brochure

12 Pages

-

Corporate Capabilities Brochure

20 Pages

-

Composite Curing Systems

8 Pages

-

ACER TECH TM

1 Pages

-

CFR - Carbon Fiber Research

2 Pages

-

Integrated Carbon Fiber Line

2 Pages

-

Carbon Fiber Oxidation Oven

2 Pages

-

Materials Brochure

4 Pages

Archived catalogs

-

VOC Thermal Oxidizer

2 Pages

-

Standard Products Brochure

12 Pages

-

Batch Oven Selection Guide

7 Pages

-

Healthcare Brochure

4 Pages

-

Electronics Brochure

4 Pages