Catalog excerpts

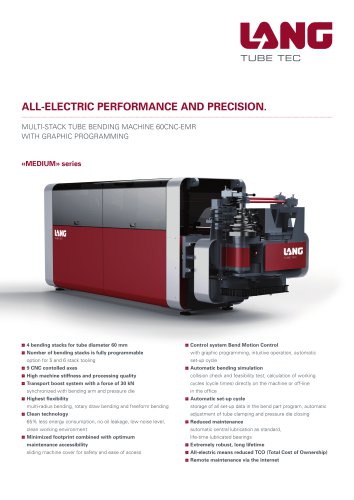

CW and CCW bending in a bending cycle □ Precise bending of highly complex part shapes through automatic change of bending direction and simultaneous movement of the axes on the bend head □ 11 CNC controlled axes Unlimited flexibility Innovative lifting table design for ergonomic loading height and constant central boost force application □ Minimized change-over work □ Clean technology 65% less energy consumption, no oil leakage, low noise level, clean working environment □ Minimized footprint combined with optimized maintenance accessibility sliding machine cover for safety and ease of access Control system Bend Motion Control with graphic programming, intuitive operation, automatic set-up cycle □ Automatic bending simulation collision check and feasibility test, calculation of working cycles (cycle times) directly on the machine or off-line in the office □ Automatic set-up cycle storage of all set-up data in the bend part program, automatic adjustment of tube clamping and pressure die closing □ Reduced maintenance automatic central lubrication as standard, life-time lubricated bearings □ Extremely robust, long lifetime □ All-electric means reduced TCO (Total Cost of Ownership) □ Remote maintenance via the internet

Open the catalog to page 1

1ANGTUBE TEC OPTIONAL EQUIPMENT TECHNICAL DATA Automatic mandrel lubrication (minimized spray lubrication option) Hitch-Feed function for bending overlong tubes Sliding machine cover □ Connection to a measuring machine (Romer, Faro, Aicon a.s.o.) with automatic data correction □ direct import of Cad data □ bender HMI in all languages □ Easy integration into automated bending cells options will be configured to meet your application requirements. Max. tube dimension with 450N/mm2 Max. tube dimension with 750N/mm2 Max. section modulus with 450 N/mm2 Max. bending speed Max. bending radius Min....

Open the catalog to page 2