Catalog excerpts

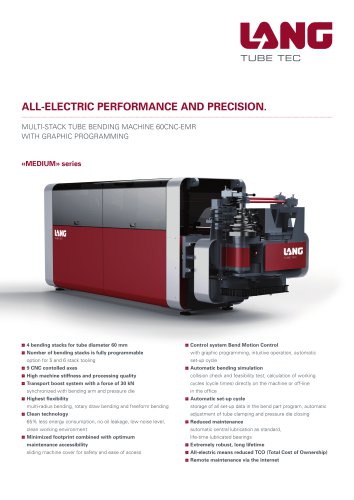

MULTi-STACK TUBE BENDiNG MACHiNE 80CNC-EMR WiTH GRAPHiC PROGRAMMiNG 4 bending stacks for tube diameter 80 mm □ With lifting table □ Number of bending stacks is fully programmable option for 5 and 6 stack tooling □ 9 CNC controlled axes High machine stiffness and processing quality Transport boost system with a force of 30kN synchronized with bending arm and pressure die Highest flexibility multi-radius bending, rotary draw bending and freeform bending □ Clean technology 65% less energy consumption, no oil leakage, low noise level, clean working environment □ Minimized footprint combined with optimized maintenance accessibility sliding machine cover for safety and ease of access Control system Bend Motion Control with graphic programming, intuitive operation, automatic set-up cycle □ Automatic bending simulation collision check and feasibility test, calculation of working cycles (cycle times) directly on the machine or off-line in the office Automatic set-up cycle storage of all set-up data in the bend part program, automatic adjustment of tube clamping and pressure die closing □ Reduced maintenance automatic central lubrication as standard, life-time lubricated bearings Extremely robust, long lifetime □ All-electric means reduced TCO (Total Cost of Ownership) □ Remote maintenance via the internet

Open the catalog to page 1

IANGTUBE TEC OPTIONAL EQUIPMENT TECHNICAL DATA automatic mandrel lubrication (minimized spray lubrication option) □ automatic wiper die lubrication (minimized spray lubrication option) □ separate drive for bend die return function □ sliding machine cover connection to a measuring machine (Romer, Faro, Aicon a.s.o.) with automatic data correction □ hand held teach pendant □ Direct import of cAD Data □ bender HMI in all languages □ easy integration into automated bending cells Max. tube dimension with 450N/mm2 Max. tube dimension with 750N/mm2 Max. section modulus with 450 N/mm2 Max. bending...

Open the catalog to page 2