Website:

DEMATIC

Website:

DEMATIC

Group: Dematic

Catalog excerpts

Dematic Multishuttle® 2 STAGING BUFFER SUBSYSTEM

Open the catalog to page 1

EXCEED COMPETITIVE DEMANDS TODAY AND INTO THE FUTURE WITH MULTISHUTTLE 2.

Open the catalog to page 2

Multishuttle 2 SCALABLE, MODULAR, HIGH DENSITY STAGING BUFFER OPERATIONAL FLEXIBILITY FOR DISTRIBUTION AND PRODUCTION LOGISTICS. As business has long known, the only future certainty is change. New products, new customers, tight deadlines, changing order profiles, high labor costs, and controlling growth are just some of the daily challenges facing logistics professionals. You need is a logistics system capable of optimizing performance that is also sufficiently flexible, modular, and adaptable to deal with changing demands. The Dematic Multishuttle 2 prepares your business for change and...

Open the catalog to page 3

FLEXIBLE LOAD HANDLING TECHNOLOGY, ENABLING HIGH PERFORMANCE STORAGE AND RETRIEVAL

Open the catalog to page 4

More Throughput in Less Space MULTISHUTTLE 2: COMPACT, HIGH RATE CAPACITY Dematic Multishuttle 2 is a highly effective system for buffering totes, cartons, or trays. It is an efficient staging solution that provides precise load sequencing at high rates, in less space, with more operational flexibility. TYPICAL APPLICATIONS Multishuttle 2 is ideal for supplying product to piece pick order fulfillment modules or mixed case pallet building operations. It can also serve as a pick face replenishment solution. In addition, Multishuttle can be applied as a short term buffer storage system or as a...

Open the catalog to page 5

The Dematic Multishuttle Subsystem FLEXIBLE, SCALABLE, MODULAR Designed with simplicity in mind, the Dematic Multishuttle 2 offers standard modular components and the flexibility to be scalable, especially for companies experiencing rapid growth and change in product demand profiles. The Dematic Multishuttle 2 System consists of multiple levels of racking, shuttles, buffer conveyors, and software. Each level includes input/output conveyor and a shuttle that travels horizontally to access loads stored in the rack structure — typically totes, cartons, or trays. An extraction device on each...

Open the catalog to page 6

Telescopic load extractor (fixed length & width) Belt conveyor load deck Telescopic load extractor (expands/ contracts to accommodate a range of load sizes) Operates at temperatures as low as -30°C, fully-automated solution for refrigerated and freezer environments Racking: Energy: Resilient: 3–4 times conventional Start small, add shuttles Fits into more spaces Precise load sequencing Less complex Simple & cost effective 24 volts DC = less energy use Multiple shuttles per aisle Manual access to inventory Load Types Operator walkway: Captive, single/double deep Plastic tote box, cardboard...

Open the catalog to page 7All DEMATIC catalogs and technical brochures

-

Autonomous Mobile Robots

2 Pages

-

GTP

12 Pages

-

Robotic Order Fulfillment

2 Pages

-

Garment on Hanger System

4 Pages

-

Put Wall

4 Pages

-

Case Pick to Pallet System

4 Pages

-

FlexSort SC3

8 Pages

-

FlexSort™ SL2

4 Pages

-

Company Overview

4 Pages

-

Dematic Modular Conveyor System

12 Pages

-

RapidStore™ ML350

4 Pages

-

RapidStore™ ML450

4 Pages

-

AMCAP

12 Pages

-

AutoStore

4 Pages

-

Dematic Sortation Solutions

20 Pages

-

Dematic Pouch System

8 Pages

-

RapidStore UL 1800

4 Pages

-

RapidStore UL1400

4 Pages

-

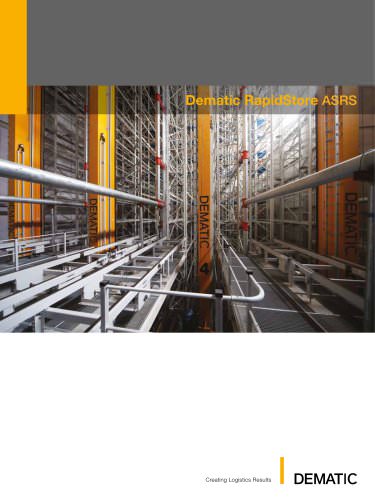

Dematic RapidStore ASRS

32 Pages

-

Dematic Services

8 Pages

-

Dematic IT Consulting

6 Pages

-

Dematic SubSuite 2.0

8 Pages

-

Dematic Sprocket CMMS

12 Pages

-

Dematic CMMS

4 Pages

-

Dematic iQ Supply Chain

4 Pages

-

Dematic iQ

4 Pages

-

Flex Series AGV-Family

4 Pages

-

FlexTruck Voice

4 Pages

-

FlexTruck Easy

4 Pages

-

Deep Lane Storage

4 Pages

-

Dematic PutWall

4 Pages

-

Dematic FlexSort SC3

8 Pages

-

Modular Conveyor System

12 Pages

-

Dematic FactBook

17 Pages

-

Dematic Quality Manual

12 Pages

-

Dematic SAP Solutions

16 Pages

-

Dematic Sortation Systems

20 Pages

-

Dematic RapidStore ASRS

20 Pages

-

Dematic Multishuttle 2

8 Pages

-

Warehouse Management Systems

12 Pages

-

Slow Movers Module

4 Pages

-

Pallet Conveyor Solutions

16 Pages

-

Pick-by-Light

8 Pages

-

The RapidPick™ System

8 Pages