Website:

DEMATIC

Website:

DEMATIC

Group: Dematic

Catalog excerpts

Automated Mixed Case Palletizing THE HIGH-PERFORMANCE SYSTEM THAT BUILDS MIXED CASE PALLETS

Open the catalog to page 1

Dematic AMCAP® – Automated Mixed Case Palletizing THE HIGH-PERFORMANCE SYSTEM THAT BUILDS MIXED CASE PALLETS AND ROLL CONTAINERS CASES ASSEMBLED ON PALLET IN STRATEGIC POSITION FOR EFFICIENT STORE REPLENISHMENT. Retailers are challenged with receiving thousands of single SKU pallets from suppliers and then re-assembling the pallets into mixed case orders for their retail stores. Traditional case pick and pallet building methods are labor intensive and often rely on manual lifting of cases, leaving workers vulnerable to injuries. Furthermore, order accuracy issues, product damage, and...

Open the catalog to page 2

Modular Sub-Systems Support Operational Flexibility COMPACT FOOTPRINT FITS INTO EXISTING FACILITIES Cases flow directly through each sub-system; trays are not required. 1. Layer Picking Robot 3. Robotic Palletizing Cell Pallets are transferred from the high-bay warehouse to an automated layer depalletizer. The Dematic Multishuttle case buffer is a high density sequencing engine that occupies a compact footprint. Once the system receives a palletizing order, the software directs the pallet building according to family groups, store planogram, and pallet stability. Each layer is placed on a...

Open the catalog to page 3

Layer Picking Robot DEPALLETIZING AND ORIENTATION OF CASES Layers of cases are removed from the pallet. Cases are singulated and reoriented. FROM PALLETS TO CASE LEVEL Pallets consisting of one stock keeping unit are conveyed to the depalletizing station. A robot depalletizes by layer onto the conveyor. From here, cases are conveyed to the next module. It supports most packaging formats, sizes and weights. It singulates the cases and can re-orient if needed. Cases are transported via conveyor network to Multishuttle sequencing buffer.

Open the catalog to page 5

Multishuttle Flex – Compact with high rate capacity Load types: Plastic tote box, cardboard carton, trays, bundles, shrink wraps Flex version: Telescopic load extractor; expands/contracts, accommodates a range of load sizes Storage density: single or multiple-deep

Open the catalog to page 6

Sequencing Buffer EFFICIENT CASE BUFFER AND SEQUENCING ENGINE Flexible, scalable and modular architecture enables the Dematic Multishuttle case buffer to adjust to the ever changing distribution environment: flexible to accommodate various case sizes, scalable to meet various activity profiles, modular to facilitate system expansion. The Multishuttle case buffer is a high density, high throughput sequencing engine that occupies a compact footprint. It can fit into existing building spaces: above docks, on a mezzanine, thereby effectively using the space available. Each Multishuttle includes...

Open the catalog to page 7

Automated palletizing on pallet or roll containers High palletizing rates Handles wide range of case sizes Stable, accurate pallet building Temperature controlled versions

Open the catalog to page 8

Robotic Palletizing Cell MIXED CASE PALLET BUILDING Cases or totes efficiently slide onto the pallets or roll containers. Cases are moved into sequenced position as directed by the system software. Cases are delivered to the RapidPall® robotic palletizing cell in precise sequence: heavy items first, fragile items last, by family group or in whatever sequence the business rules dictate. Due to the enhanced mechanical design, RapidPall supports palletizing on pallets and roll containers in one cell and supports high palletizing accuracy. With improved load density compared to manually stacked...

Open the catalog to page 9

OPERATIONAL INSIGHT Operational control of palletizing process Efficient location management by dynamic slotting Visibility & insight dashboards Optimized case sequencing strategies PackBuilder extensions Packaging variation management Web-enabled use

Open the catalog to page 10

Control Software REAL-TIME VISIBILITY AND CONTROL SYSTEM For the AMCAP system, Dematic iQ software manages and directs the entire process. It tracks the location of each case in the Multishuttle rack; the system put-away logic may be random or may be configured according to specific rules. For example, if SKU velocity rules are deployed, fast moving items are stored at the forward positions in the aisle. When a store order needs to be palletized for shipping, the software calculates how to arrange the cases on the pallet or roll containers. It directs the Multishuttle sub-system to release...

Open the catalog to page 11

Mixed case pallets are stretch wrapped after palletizing process. Depalletizing is accomplished using a delayering robot.

Open the catalog to page 12All DEMATIC catalogs and technical brochures

-

Autonomous Mobile Robots

2 Pages

-

GTP

12 Pages

-

Robotic Order Fulfillment

2 Pages

-

Garment on Hanger System

4 Pages

-

Put Wall

4 Pages

-

Case Pick to Pallet System

4 Pages

-

FlexSort SC3

8 Pages

-

FlexSort™ SL2

4 Pages

-

Company Overview

4 Pages

-

Dematic Modular Conveyor System

12 Pages

-

RapidStore™ ML350

4 Pages

-

RapidStore™ ML450

4 Pages

-

Dematic Multishuttle 2

8 Pages

-

AutoStore

4 Pages

-

Dematic Sortation Solutions

20 Pages

-

Dematic Pouch System

8 Pages

-

RapidStore UL 1800

4 Pages

-

RapidStore UL1400

4 Pages

-

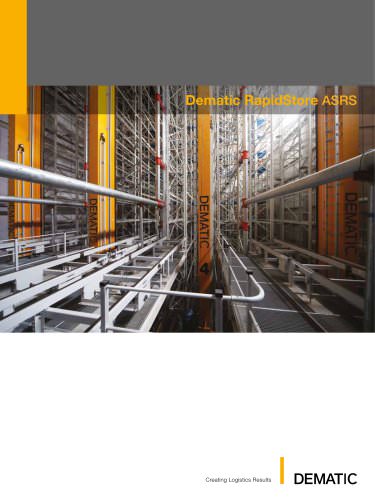

Dematic RapidStore ASRS

32 Pages

-

Dematic Services

8 Pages

-

Dematic IT Consulting

6 Pages

-

Dematic SubSuite 2.0

8 Pages

-

Dematic Sprocket CMMS

12 Pages

-

Dematic CMMS

4 Pages

-

Dematic iQ Supply Chain

4 Pages

-

Dematic iQ

4 Pages

-

Flex Series AGV-Family

4 Pages

-

FlexTruck Voice

4 Pages

-

FlexTruck Easy

4 Pages

-

Deep Lane Storage

4 Pages

-

Dematic PutWall

4 Pages

-

Dematic FlexSort SC3

8 Pages

-

Modular Conveyor System

12 Pages

-

Dematic FactBook

17 Pages

-

Dematic Quality Manual

12 Pages

-

Dematic SAP Solutions

16 Pages

-

Dematic Sortation Systems

20 Pages

-

Dematic RapidStore ASRS

20 Pages

-

Dematic Multishuttle 2

8 Pages

-

Warehouse Management Systems

12 Pages

-

Slow Movers Module

4 Pages

-

Pallet Conveyor Solutions

16 Pages

-

Pick-by-Light

8 Pages

-

The RapidPick™ System

8 Pages