Website:

Demag Cranes & Components GmbH

Website:

Demag Cranes & Components GmbH

Group: konecranes

Catalog excerpts

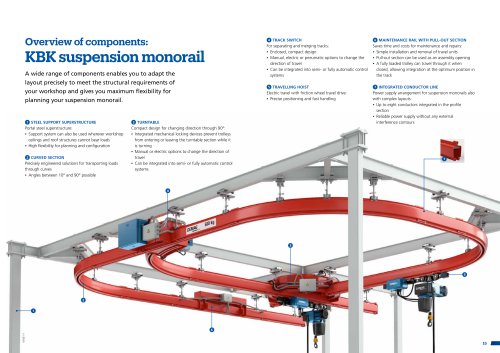

For separating and merging tracks: •• Enclosed, compact design •• Manual, electric or pneumatic options to change the direction of travel •• Can be integrated into semi- or fully automatic control systems KBK suspension monorail A wide range of components enables you to adapt the layout precisely to meet the structural requirements of your workshop and gives you maximum flexibility for planning your suspension monorail. 1 STEEL SUPPORT SUPERSTRUCTURE Portal steel superstructure: •• Support system can also be used wherever workshop ceilings and roof structures cannot bear loads •• High flexibility for planning and configuration 2 CURVED SECTION Precisely engineered solutions for transporting loads through curves •• Angles between 10° and 90° possible Electric travel with friction wheel travel drive: •• Precise positioning and fast handling Compact design for changing direction through 90°: •• Integrated mechanical locking devices prevent trolleys from entering or leaving the turntable section while it is turning •• Manual or electric options to change the direction of travel •• Can be integrated into semi- or fully automatic control systems 6 MAINTENANCE RAIL WITH PULL-OUT SECTION Saves time and costs for maintenance and repairs: •• Simple installation and removal of travel units •• Pull-out section can be used as an assembly opening •• A fully loaded trolley can travel through it when closed, allowing integration at the optimum position in the track 7 INTEGRATED CONDUCTOR LINE Power supply arrangement for suspension monorails also with complex layouts: •• Up to eight conductors integrated in the profile section •• Reliable power supply without any

Open the catalog to page 1

Specialised handling for stores KBK STACKER CRANES FURTHER DETAILS •• Combination of KBK double-girder suspension crane and special stacker trolley •• Can be turned through a range of 360°, by hand •• Long and cross travel always by hand, lifting motion via electric chain hoist Unit loads weighing up to 500 kg can be transported and stored with ease – load handling attachments can be simply adapted to the type of load. All tasks can be performed in one operating cycle. Additional equipment such as ladders or order-picking trolleys is not needed. Mobile workplace units KBK PORTAL CRANES For...

Open the catalog to page 2

Efficient workplace design FURTHER DETAILS Effective workplace crane solution to serve a specific working area. Demag slewing jib cranes can be installed virtually anywhere for handling loads weighing between 80 and 10,000 kg. They ensure that all types of workpieces can be lifted quickly and easily, transported gently and deposited precisely, providing handling performance at machine tools and assembly stations, as well as in outdoor storage yards and on loading ramps. •• Wall-mounted slewing jib cranes •• Pillar-mounted slewing jib cranes (also available with 2 jibs) •• Pillar-mounted...

Open the catalog to page 3

Demag hoist units, control and load attachment Demag hoist units are available with a wide range of load capacities, lifting speeds and features. They can also be used with a broad selection of controls and load handling attachments. COMPREHENSIVE STANDARD FEATURES FOR DEMAG CHAIN HOISTS: •• High level of safety thanks to 24 V contactor control and operating limit switches Perfect combination DEMAG KBK AND HOIST UNITS •• Flexibility thanks to two sizes of suspension bracket •• Simple commissioning thanks to plug connections •• Gearbox, brake and slipping clutch maintenance-free for up to 10...

Open the catalog to page 4

Demag KBK product configurator You can configure a KBK system to meet your specific needs quickly and easily in just a few steps with our online planning tool. You always receive the best possible solution for your requirements with reliable and plausible results. Your direct access to our product configuration tools: www.demag-designer.com YOUR BENEFITS: •• Easy to use •• Specify products to meet your needs •• Save your configuration •• Immediate results: •• Product description •• Technical data •• CAD geometry data •• Circuit diagrams •• Documentation •• Online ordering via Demag Shop...

Open the catalog to page 5

There is a solution for everything ... KTR Kupplungstechnik Rheine, Germany CUSTOMER REQUIREMENTS •• Versatile handling concept with modular material flow system •• Overhead area-serving crane solution without using any floor space •• Horizontal transport of loads to the assembly and test stations with smooth-running crane systems •• Maximum flexibility thanks to multi-functional and modular crane system •• Optimum use of the available space thanks to custom-made support structure for overhead crane system •• Maximum efficiency thanks to high-capacity crane and track profile section ••...

Open the catalog to page 6

Hawe Hydraulik Munich, Germany CUSTOMER REQUIREMENTS •• Ergonomic workplace design to improve working environment and productivity •• Smooth-running, manually controlled crane installations for assembly processes •• Use of a modular crane system that can also be adapted for future production layouts •• User-friendly, ergonomic solutions for the assembly stations: cranes can be moved with very little force •• Visually pleasing integration into a bright production environment •• Simple integration of new components and replacement of existing units with ease at any time DEMAG SOLUTION ••...

Open the catalog to page 7

Wenden, Germany •• Improved precision in all assembly operations thanks to the use of KBK single-girder cranes with Demag Manulift •• Modifications at a later date possible at any time thanks to modular system design •• High flexibility by relocating the cranes thanks to standard girder lengths of 5.5 m DEMAG SOLUTION •• 12 KBK suspension cranes for area-serving coverage of all workplaces in pre- and final assembly •• Crane runways suspended direct from the building superstructure •• Use of KBK II-H profile sections for crane runways eliminates the need for additional steelwork Efficient...

Open the catalog to page 8All Demag Cranes & Components GmbH catalogs and technical brochures

-

Demag DVR rope hoist

8 Pages

-

Demag DC chain hoists

21 Pages

-

Demag wheel range

20 Pages

-

Demag product range

32 Pages

-

DCBS chain hoist

4 Pages

-

V-type crane Brochure en

11 Pages

-

DRC-MP series Brochure en

4 Pages

-

Demag industrial drives

4 Pages

-

Demag drives

24 Pages

-

21315444_LRS_Part 2

11 Pages

-

Demag Chain Hoists DC

4 Pages

-

20875544_SSK_WSK

9 Pages