Catalog excerpts

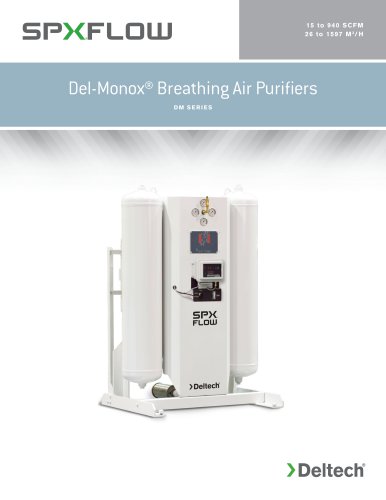

Del-Monox Breathing Air Purifiers... ® T I M E-PR OV E N R E L IAB I L IT Y Since 1961, Deltech has delivered products In 1966, Deltech introduced the industry’s first engineered, contaminant engineered to efficiently remove contaminants removing system to convert compressed air to safe breathing air. Over time, from compressed air systems across multiple the designs have advanced employing the latest in filtration and dehydration applications. Moving forward our designs have advanced, employing the latest in filtration and dehydration technology. Today, Deltech prides itself on being a...

Open the catalog to page 2

Applications PETR O C H E M I CA L The oil and gas industries select DM Series breathing air purifiers to protect workers from the inhalation of hazardous fumes, gases, and vapors inherent in the manufacturing process. AS B E STO S A BAT E M E N T Asbestos was a commonly used insulation material for old dwellings. DM Series Breathing Air Purifiers provide suitable breathing air to workers in asbestos abatement applications. PA I N T S P R AY Automotive body shops utilize atomized paint to spray vehicles. Workers exposed to airborne paint emissions benefit from DM Series Breathing Air...

Open the catalog to page 3

SIX STAGE FILTRATION Stage 1 General purpose filter removes solid and liquid contaminants down to 1.0 micron Stage 2 High efficiency oil removal filter captures liquid aerosols and sub-micronic particles down 0.01 micron Stage 3 Pressure-swing regenerative desiccant dryer removes water vapor to ensure the effectiveness of the catalyst bed Stage 4 Dried air travels through a catalytic converter reducing CO concentrations by converting CO to CO2 Stage 5 Particulate removal filter collects contaminants 1.0 micron and larger from the purified air stream Stage 6 Activated carbon filter removes...

Open the catalog to page 4

Features and Options FILTRATION & MONITORING • Pre-filtration removes solids and oils • After-filters collect remaining particles and adsorb vapor • CO catalyst converter • Air sample ports for optional analyzer installation MOISTURE INDICATOR • Visual color change PRESSURE GAUGES • Left / right tower • Inlet / outlet purifier • Purge pressure STANDARD CONTROLLER • NEMA 4/4X with critical LED indicators • Soft on / off switch with two power recovery modes • Switching failure alarms • Adjustable service indications • Tower / valve status LEDs • Voltage free common alarm contacts • RS-232...

Open the catalog to page 5

OPTIMIZING CAPACITY Breathing air produced by a Breathing Air Purifier system can supply various levels of use. To select a DM Series purifier, first determine the air pressure at the purifier inlet and the maximum breathing air flow required at a given time. The chart below illustrates an example of DM Series estimated capacities based on 6-15 scfm (10-25 m3/h) per hood, helmet or suits as calculated in the sizing table. * Contact hood manufacturer for actual capacity before sizing purifier. MODEL SPECIFICATIONS VOLTAGES V/PH/HZ 1 Flow capacity rated at CAGI conditions: 100 psig (7.0 bar)...

Open the catalog to page 6

CAPACITY CORRECTION FACTORS To adjust capacity for conditions other than rated, use the correction factors (multipliers) for inlet air temperature and pressure shown below. Example: What is the capacity of a 205 scfm (348 nm3/h) model when the compressed air at the inlet is 130 psig (9 bar) and 110°F (43°C)? Answer: 205 scfm (348 nm3/h) (rated flow from Product Specifications Table) x 1.08 (correction factor for inlet air temperature and pressure) = 221 scfm (375 nm3/h)

Open the catalog to page 7

4647 SW 40th Avenue Ocala, Florida 34474-5788 U.S.A. P: (724) 745-8647 F: (724) 745-4967 E: deltech.americas@spxflow.com www.spxflow.com/deltech SPX FLOW, Inc. reserves the right to incorporate our latest design and material changes without notice or obligation. Design features, materials of construction and dimensional data, as described in this bulletin, are provided for your information only and should not be relied upon unless confirmed in writing. Please contact your local sales representative for product availability in your region. For more information visit www.spxflow.com. The...

Open the catalog to page 8All DELTECH catalogs and technical brochures

-

DBA-NA_2-web

8 Pages

-

DMD and ESM Series

8 Pages

-

Condensate Management

4 Pages