Catalog excerpts

MOTOR MOUNTED BRAKES BRAKING UNLIMITED

Open the catalog to page 1

Content Spring Set Brakes SFB Series 3 - 8 Spring Set Brake EFB-N 9 - 12 Brake Control Unit BCU2001 25 - 27 Brake Control Unit BCMS-4 29 - 31

Open the catalog to page 2

Spring Set Brakes SFB Series PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2015 High Performance Easy Maintenance

Open the catalog to page 3

Main Features Special brake torque: Lower brake torque = type SFB Higher brake torque = type SFB-SH Holding brake torques available on request Micro- or proximity switches: • Monitoring the function on/off • Maximum air gap (wear-monitoring) Lateral junction box Tacho preparation with all mounting parts Cover bore Shaft sealing Special voltage Anti condensation heater Radial cable outlet Special flange Please Note We supply a detailed operating manual with every order. Nevertheless, we would point out that brakes are only as safe as the servicing and maintenance performed while...

Open the catalog to page 4

Spring Set Brake SFBElectromagnetic Two Disc, Spring Set BrakeRev. 05-08 Keyways for keys acc. to DIN6885 Bl.' width accuracy P9. Protection IP67 Alterations reserved without notice

Open the catalog to page 5

Brake size Keyways for keys acc. to DIN6885 Bl.1, width accuracy P9. Protection IP67 Alterations reserved without notice

Open the catalog to page 6

Spring Set Brake SFB-SH Electromagnetic Two Disc, Spring Set Brake Increased brake torque Keyways for keys acc. to DIN6885 Bl.' width accuracy P9. Protection IP67 Alterations reserved without notice

Open the catalog to page 7

Brake size Keyways for keys acc. to DIN6885 Bl.1, width accuracy P9. Protection IP67 Alterations reserved without notice

Open the catalog to page 8

Spring Set Brake EFB-N PINTSCHBUBENZER is certified according to DIN EN ISO 9001:2015 Reliable High Performance Robust Easy Maintenance Compact Tried and Trusted

Open the catalog to page 9

Main Features Electrical equipment One-way-, bridge- and switching rectifier Protection element Please Note We supply a detailed operating manual with every order. Nevertheless, we would point out that brakes are only as safe as the servicing and maintenance performed while they are in operation. The guarantee for the correct functioning of our brakes is only valid if the user adheres to the German DIN standard 15434 part 2 (drum and disc brakes, servicing and maintenance in operation), or to comparable standards in his own country. PINTSCH BUBENZER Service This includes the verification of...

Open the catalog to page 10

Spring Set Brake EFB-N Electromagnetic Two Disc, Spring Set Brake Brake size

Open the catalog to page 11

Spring Set Brake EFB-N Electromagnetic Two Disc, Spring Set Brake Nuts for keys according to DIN 6885 sheet 1, tolerance field for the nuts width P9. Alterations reserved without notice. Technical, measures and design are subject to change. Friction plate

Open the catalog to page 12

PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2015 High Performance Easy Maintenance

Open the catalog to page 13

Main Features Please Note We supply a detailed operating manual with every order. Nevertheless, we would point out that brakes are only as safe as the servicing and maintenance performed while they are in operation. The guarantee for the correct functioning of our brakes is only valid if the user adheres to the German DIN standard 15434 part 2 (drum and disc brakes, servicing and maintenance in operation), or to comparable standards in his own country. PINTSCH BUBENZER Service This includes the verification of the brake selection, if required. A detailed questionnaire is provided for this...

Open the catalog to page 14

Spring Set Brake KFBElectromagnetic Two Disc, Spring Set BrakeRev. 10-09 The larger dimension belongs to the larger assigned brake. Alterations reserved without notice.

Open the catalog to page 15

Brake rectifier BGL+EGL High Performance PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2015 Easy Maintenance

Open the catalog to page 17

Main Features EMC compatibility Top-hat rail mounted Combinable with Brake Control Unit BCU2001 Integrated protective element Integrated spark quench element Specific Features for the rectifiers BGL and EGL ■ Prepared for switching AC and DC circuits simultaneously Installation in cabinet Specific Features for the protective element PE 400/150/5 I To be connected parallel to the output of the rectifiers BGL, EGL and SGL to increase the interruption capacity Specific Features for the rectifiers FWR and HWR ■ Prepared for switching AC and DC circuits simultaneously Installation in junction...

Open the catalog to page 18

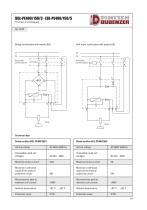

Bridge rectification with module BGL Half-wave rectification with module EGL Technical data

Open the catalog to page 19

Full wave rectifier FWR-PE400/150/3 Principal circuit diagram Technical data

Open the catalog to page 20

Half wave rectifier HWR-PE400/150/5 Principal circuit diagram Technical data

Open the catalog to page 21

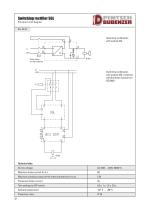

Principal circuit diagram Switching rectification with module SGL Switching rectification with module SGL combined with the Brake Control Unit BCU2001 Technical data

Open the catalog to page 22

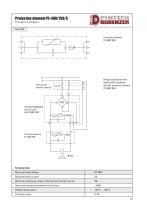

Protective element PE-400/150/5 Principal circuit diagram Rev. 03-09 Bridge rectification with module BGL combined with the protective element PE-400/150/5 PINTSCH BUBENZER Brake module BGL-PE400/150/3 Technical data Maximum brake voltage: Maximum brake current: Maximum continuous output of the internal protective circuit: Disconnection peak at maximum coil current: Ambient temperature: Protection class:

Open the catalog to page 23

Brake Control Unit BCU2001 PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2015 High Performance Easy Maintenance

Open the catalog to page 25

Main Features EMC compatibility Maximum air gap (wear) indication by LED Maximum air gap indication by relay contact Function on/off indication by LED Function on/off indication by relay contact No sensors on the brake No sensor wiring to the brake Perfect retrofit equipment Directly connectable with PLC systems AC and DC auxiliary power supplies applicable Top-hat rail mounted Applications Container cranes Ship winches Automatic racking systems Conveyor belts General electrical drives Options Please Note We supply a detailed operating manual with every order. Nevertheless, we would point...

Open the catalog to page 26

Brake Control Unit BCU2001 Principal circuit diagram Technical data

Open the catalog to page 27

Brake Control Unit BCMS-4 PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2015 High Performance Easy Maintenance

Open the catalog to page 29

Main Features The BCMS-4 is a micro-controller-based monitoring and switching device for spring applied brakes of the SFB and KFB series. Through measurement and analysis of current and voltage of the outgoing two-wire lines of the individual brakes wear and switching state of each electromagnetic spring-applied brake can be detected in some distant mounting position. There can be up to four brakes operated and evaluated simultaneously. The operation of the brakes is fundamentally with rapid releasing and closing of the brakes. Please Note We supply a detailed operating manual with every...

Open the catalog to page 30All DELLNER BUBENZER Germany GmbH catalogs and technical brochures

-

Brake System For Eot Cranes

70 Pages

-

Wind power

48 Pages

-

Brake systems for steel mills

91 Pages

-

Couplings

56 Pages

-

buel

32 Pages

-

Brochure Crane systems

76 Pages

-

Brochure "Mining"

96 Pages

-

Brochure "Ship's chandlery"

46 Pages

-

Imagebrochure "PINTSCH BUBENZER"

20 Pages