Catalog excerpts

PINTSCH BUBENZER A Schaltbau Company Ship & offshore. Safety.

Open the catalog to page 1

Content Hydraulic Disc Brakes Electromagnetic Disc Brakes Brake Control Unit BCU2001 Brake Control Unit BCMS-4

Open the catalog to page 2

Hydraulic Caliper Disc Brakes SF Series PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2008 High Performance Robust Design Easy Maintenance

Open the catalog to page 3

Main Features Two identical caliper halves, ready for operation, with spring packs set to nominal force and limit switch release control Options Limit switch wear control Sintered linings Complete piped supports for one or more calipers Up to 2 mm air gap between brake pad and disc Hydraulic power units Easy, manual pad wear compensation Special seals for flameproof fluids Organic, non-asbestos linings Cleaning pads Brake discs CMB contact force measurement Applications The high capacity of these brakes makes them particularly suitable as secondary emergency brakes on hoist gears and on...

Open the catalog to page 4

Disc Brake SF Dimensions and technical data Rev. 12-06 Bleeder valve Pressure connection Data per caliper half *) Average friction factor of standard material combination All dimensions in mm. Alterations reserved without notice. Brake torque MBr in Nm = FA (kN) x µ x d1 (mm) Brake disc data Please indicate required mounting position. d4 = d2-420 mm d2-420 mm d2-490 mm d2-620 mm d2-700 mm d2 = Brake disc diameter in mm d1 = Friction diameter in mm d4 = Max. permissible drum or hub diameter in mm b1 = Disc thickness in mm (min. 30) B3

Open the catalog to page 5

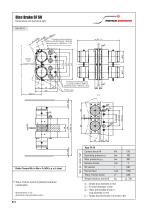

Disc Brake SF 50 Dimensions and technical data Rev. 02-14 m) 0m 180 6 -20 (min. 90 d2 d2 4 x hexagon bolt according to 2-4 d1 = =d DIN 931 or DIN EN ISO 4017 - M36-10.9 d4 tightening torque = 3550 Nm (μ = 0,12) Bleeder valve 2 x hexagon socket head screw according to DIN 912 - M24-8.8 tightening torque = 675 Nm (μ = 0,12) 175 Pressure port All dimensions in mm Alterations reserved without notice Data per caliper half Release stroke Weight (without bracket) *) Theor. friction factor of standard material combination Theor. friction factor d2 = Brake disc diameter in mm d1 = Friction diameter...

Open the catalog to page 6

Disc Brake SF Hydraulic power unit for one or more calipers Rev. 12-06 Example: 2nd circuit (Option) Standard configuration up to 4 SF10/SF15 up to 2 SF24 Terminal box Motor: Pump: Pressure: Tank: Weight: Heater (Option) The flow diagram shows the general arrangement of the hydraulic power unit, including hand pump for emergency manual release of the brakes. Catch basin (Option) The two solenoid valves are connected in parallel (redundancy). After the nominal pressure is reached, the idler valve switches into idle running. The motor is continuously energized. Hydraulic power unit limit...

Open the catalog to page 7

Piping Samples Disc brakes SF and BSC Rev. 09-02 Example: Piping of one brake unit – one hydraulic power unit Equal Tee Power Unit Hose Pipe Example: Piping of two brake units - one hydraulic power unit Hose Equal Tee Distributor Power Unit Attention: For operating two brake units with one power unit please note, that the power unit should be installed between the brakes in the centre to achieve almost equal pipe length on both sides (equal apply time of brakes).

Open the catalog to page 8

Band Brake Type BHB Dimensions and technical data Rev. 11-04 *) Average friction factor of standard material combination Other diameters and release by thruster upon request. All dimensions in mm Alterations reserved without notice Brake type

Open the catalog to page 9

Hydraulic Caliper Disc Brakes BSC Series PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2008 High Performance

Open the catalog to page 11

Main Features Two identical caliper halves, ready for operation, with spring packs set to nominal force Limit switch release control Up to 1 mm air gap between brake pad and disc Sintered linings Easy, manual pad wear compensation Complete piped supports for one or more calipers Organic, non-asbestos linings Hydraulic power units Limit switch wear control Special seals for flameproof fluids Cleaning pads Brake discs Applications The high capacity of these brakes makes them particularly suitable as service- or secondary emergency brakes e.g. on hoists, slewing drives and belt conveyors Other...

Open the catalog to page 12

Disc Brake BSC Dimensions and technical data Rev. 12-06 Bleeder valve *) Average friction factor of standard material combination All dimensions in mm Alterations reserved without notice Data per caliper half t=Pressure connection Type BSC a b b2 c c1 d d3 e f g h i k l m n p q r s t Bolt ø Bolt material Tighten. torque, Nm Contact force FA kN Op. pressure bar Max. pressure bar Release stroke mm Oil volume l Pad surface cm2 Theor. friction µ* Weight (kg) Brake disc data 2 3 Please indicate required mounting position. d2 = Brake disc diameter in mm d1 = Friction diameter in mm d4 = Max....

Open the catalog to page 13

Disc Brake BSC Hydraulic power unit for one or more calipers Rev. 09-02 Example: Standard configuration up to 4 BSC 100.3 Motor: 3 kW Pump: 9 l/min Pressure: 180 bar Tank: 30 l The flow diagram shows the general arrangement of the hydraulic power unit, including hand pump for emergency manual release of the brakes. Hydraulic power unit limit The two solenoid valves are connected in parallel (redundancy). After the nominal pressure is reached, the idler valve switches into idle running. The motor is continuously energized. Pressure switch, temperature switch, space heater and other...

Open the catalog to page 14

Spring Set Brakes SFB Series PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2008 High Performance Easy Maintenance

Open the catalog to page 15

Main Features Spring applied safety brake Special brake torque: Electromechanically released Lower brake torque Higher brake torque Protection-class IP67 Double wear reserve by single air gap adjustment High work capacity High wear resistance because of high abrasion resistance type SFB type SFB-SH Holding brake torques available on request Micro- or proximity switches: • Monitoring the function on/off • Maximum air gap (wear-monitoring) Lateral junction box Functional without cover Tacho preparation with all mounting parts Emergency release screws Cover bore Shaft sealing Applications...

Open the catalog to page 16All DELLNER BUBENZER Germany GmbH catalogs and technical brochures

-

Brake System For Eot Cranes

70 Pages

-

Wind power

48 Pages

-

Brake systems for steel mills

91 Pages

-

Motor mounted Brakes

32 Pages

-

Couplings

56 Pages

-

buel

32 Pages

-

Brochure Crane systems

76 Pages

-

Brochure "Mining"

96 Pages

-

Imagebrochure "PINTSCH BUBENZER"

20 Pages