Website:

Delimon

Website:

Delimon

Group: Bijur

Catalog excerpts

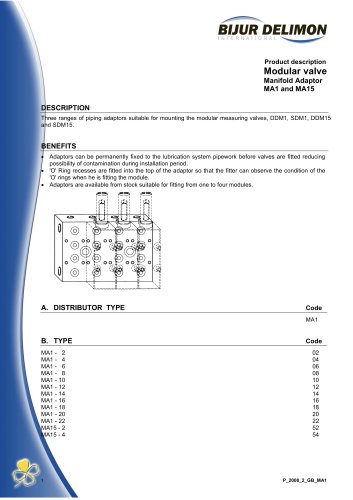

Product description DM Measuring valve DESCRIPTION A range of line mounted, adjustable metering units for use with dualine lubrication systems, whereby pressurisation of either line discharges a fixed volume of lubricant to the lubrication point. Metering units can be supplied with one to four independent operating sections. One single discharge connection for each operating sectionso that the discharge to each bearing can be individually adjusted. Positive hydraulic coperation. Visual indicator showing operation. Five discharge ranges. Stepless wide adjustment within each range to provide bearing with its ideal lubricant injection volume. OPERATION 1. With the reversing valve on the pump set to direct flow into the upper supply line, pressurised lubricant entering the valve forces the inlet piston down. This allows pressure to be applied to the top of the main discharge piston which, then begins to move downwards. 3. When the reversing valve on the pump changes over to direct the pump flow to the lower supply line, pressurised lubricant entering the valve forces the inlet piston up, allowing pump pressure to be applied to the bottom of the discharge piston. The discharge piston begins to move up. 1 / 5 2. Maintained pump pressure on the supply line forces this main discharge piston to the lowest point of its traveland the valve complete its operation in one direction, delivering the measured charge to the bearing. Further application of pressure to the upper supply line will have no effect. 4. Maintained pump pressure on the supply line forces this main discharge piston to the uppermost point of its travel, and the valve completes its operation in another direction, delivering the second measured charge to the bearing. Further application of pressure to the lower supply line will have no effect.

Open the catalog to page 1

The valve discharge must be set on site to suit the application. This will be found by examination of the bearing or slide after the initial operation. If excess lubricant is present, reduce the valve stroke. If dry, increase the valve stroke. The cycle between cycles may also have to be adjusted. Discharge per outlet per stroke (cm3) Maximum 1,20 2,25 1,10 14,25 28,50

Open the catalog to page 2

SPECIFICATION (continuation) Max supply pressure Max discharge pressure Temperature range Lubricant Materials Body Pistons Gland Seals Indicator Gland covers 350 bar 70 bar - 20° to + 90° C Oil or grease (N° 3 NLGI max) Steel zinc plated Hardened steel DM60 - Steel. Others Brass DM60 - Nitrile. Others Viton Stainless steel Plastic SET UP All ports are suitable for BSB taper fittings. Extension nipples may be required to allow connections to central ports especially at the gland end. Valves have two outlet ports for each operating section. If an odd number of outlets is required either to...

Open the catalog to page 3

DIMENSIONS TABLE Dimensions (mm) Pipe connections

Open the catalog to page 4

Bijur Delimon United Kingdom Ramsden Court, Ramsden Road Rotherwas Industrial Estate Hereford HR2 6LR Tel : +44 (0) 1432 365 000 Fax : +44 (0) 1432 365 001 info@delimon.co.uk www.bijurdelimon.com Bijur Delimon France BP 50 ZI de Courtabœuf 5, Avenue de I'Atlantique 91942 Courtaboeuf Cedex Tel : (33 )1 692 985 85 Fax : (33) 1 690 776 27 contact@bijurdelimon.com www.bijurdelimon.com Bijur Delimon No B-5 & 6, A Block, SNS Arcade, Airport Road (HAL),BANGALORE India 560010 Tel : (91 0 )80 2522 1541 / 3959 / 652 mksantosh@bijurdelimon,in www,bijurdelimon,com Bijur Delimon Ireland Gort Road Ennis,...

Open the catalog to page 5All Delimon catalogs and technical brochures

-

Pneumatic Pump TP

4 Pages

-

Flushing Rig Hire

2 Pages

-

Application DA Pumps

4 Pages

-

Re-circ Oil Systems

2 Pages

-

Constant Level Oiler

2 Pages

-

Oval gear monitors

2 Pages

-

Flow indicators

2 Pages

-

Flow Meters

2 Pages

-

ZEM Injector

9 Pages

-

Direct Mount Injectors ‘ZDM’

8 Pages

-

DDJ & DDU Measuring valve

4 Pages