Website:

DELAVAN France

Website:

DELAVAN France

Group: Goodrich

Catalog excerpts

rip SDX Spray Drying Product Guide

Open the catalog to page 1

In addition, Delavan offers:-• Durability and wear resistance Our nozzles are available in materials that resist chemical attack such as plastics, ceramics, sintered carbides and various grades of stainless steel. • Customisation Delavan Spray Drying Nozzles reflect years of dedication to quality, flexibility and reliability. Since 1935, the Delavan name has become synonymous with precision engineering, proven techniques and product satisfaction. Today Delavan continues to be a leader in the spray drying industry by staying at the forefront of research and development in new materials,...

Open the catalog to page 2

Typically, a spray drying nozzle will produce droplets as small as 1 to 2 micron and as large as 400 to 500 micron. However, the majority will be within a range of 50-200 micron. The narrower the range of droplet size the more suited it is to spray drying, with a "mono -range" being the ultimate goal for most operators. The atomiser must fulfil several important functions. Spray Angle 1. It must disperse the feed material into small droplets, which should be well distributed within the dryer and mixed thoroughly with the hot gas. The spray angle in spray drying is usually in the 60° to 90°...

Open the catalog to page 3

Overview For over three decades, Delavan the leader in the spray dry industry, continues the tradition with the original SDX™ family of products. This product line specifically designed for the spray drying industry includes five centrifugal pressure nozzles; the SDX, SDX III, SDX V, Mini SDX and SDX Compact. Each of these five products is built on Delavan’s unique single inlet spiral swirl chamber design and highly polished orifice. This combination swirl chamber and orifice produces a limitless number of combinations to supply virtually any flow rate and spray angle. This means the nozzle...

Open the catalog to page 4

SDX V Features This cassette style eight part construction nozzle is made from Stainless Steel using retaining ring, single thickness swirl chamber and self-aligned orifice metering set in tungsten carbide with Viton or Silicone o-ring. Hand tight assembly with a maximum design pressure of 5,000 psig {345 bar} and temperature of 300º F {149º C}. MINI SDX Features This low flow five part construction nozzle is made from Stainless Steel using a mini swirl chamber and mini orifice metering set in tungsten carbide with a Viton o-ring. Hand tight assembly with mini-sdx tool for a maximum design...

Open the catalog to page 5

Contact our Helpline for any special requirements: Tel: +44 (0)151 424 6821 or inside USA Toll Free: 1-800 DELAVAN E-mail:delavanspray0goodrich.com or sales0delavan.co.uk • Web:www.delavan.com

Open the catalog to page 6

Contact our Helpline for any special requirements: Tel: +44 (0)151 424 6821 or inside USA Toll Free: 1-800 DELAVAN E-mail:delavanspray0goodrich.com or sales0delavan.co.uk • Web:www.delavan.com

Open the catalog to page 7

MINI SDX DESCRIPTION AND PART NUMBERS * Specify Orifice Size from Capacity Chart, on page 5 Please note special materials are available on request for particular applications please contact the factory for price and delivery. SEAL KIT (24 O-RINGS) Part No. Description Material A49109005 Mini SDX Seal Kit Viton MINI SDX SWIRL CHAMBER PART NUMBERS MINI SDX Assembly Procedure: 1. Place the nozzle body (A) thread side up on to a flat surface. 2. Press the orifice disc (B) cone face down into the body. 3. Hand tighten the orifice disc (B) with the assembly/ disassembly tool P/N 36386. 4. Place...

Open the catalog to page 8

SDX SDX DESCRIPTION AND PART NUMBERS SEAL KIT (10 OF EACH O-RING) Part No. Description Material SDX Seal Kit SDX Seal Kit SDX Seal Kit SDX Seal Kit SDX Seal Kit Nylon Aluminium Copper PTFE Hard Fibre SDX & SDX III SWIRL CHAMBER/END PLATE COMBINED DESCRIPTION AND PART NO. * Specify orifice size and swirl chamber suffix from capacity chart, on page 5 Please note special materials are available on request for particular applications - please contact the factory for price and delivery. SDX Assembly Procedure: 1. Place the nozzle body (A) thread side up on a flat surface. 2. Place the orifice...

Open the catalog to page 9

SDX III SDX III DESCRIPTION AND PART NUMBERS Description * Specify Orifice Size from Capacity Chart, on page 5. Part No. Description Material A487250001 SDX III Seal Kit Silicone A487250027 SDX III Seal Kit Viton Please note special materials are available on request for particular applications -please contact the factory for price and delivery. SDX III Assembly Procedure: 1. Place the body (A) thread side up on a flat surface. 2. Make sure the orifice o-ring (B) is pressed snugly to the nozzle body (A). 3. Place the orifice disc (C) with bevelled side down into the body (A). 4. Use your...

Open the catalog to page 10

COMPACT SDX SEAL KIT (12 OF EACH O-RING) COMPACT SDX DESCRIPTION AND PART NUMBERS * Specify Orifice Size from Capacity Chart, on page 5. Please note special materials are available on request for particular applications - please contact the factory for price and delivery. COMPACT SDX SWIRL CHAMBER PART NUMBERS c?. SWIRL CHAMBER RETAINER Compact SDX Assembly Procedure: 1. Place the nozzle body (A) thread side up on a flat surface. 2. Place the orifice o-ring (B) into nozzle body (A). 3. Place the orifice disc (C) onto the orifice o-ring (B) protruding side down. 4. Secure the swirl chamber...

Open the catalog to page 11

SDX V SEAL KIT (12 OF EACH O-RING) SDX V DESCRIPTION AND PART NUMBERS * Specify Orifice Size from Capacity Chart, on page 5. Please note special materials are available on request for particular applications - please contact the factory for price and delivery. Description Material W197690016 SDX V Seal Kit Viton W197690024 SDX V Seal Kit Silicone SDX V SWIRL CHAMBER PART NUMBERS SDX V Assembly Procedure: 1. Place the nozzle body (A) thread side up on a flat surface. 2. Insert the orifice o-ring (B). 3. Insert the orifice disc (C) into the nozzle body (A) with the "orifice” nose ie., the...

Open the catalog to page 12

Cone Faced Bodies and Butt Wetd AdaptorsThe following are various special bodies, adaptors and tools that are available for the SDX nozzle range. CONE FACE BODY These are designed to prevent build up of sprayed product on the nozzle face and are available with cone angles of 70°, 80° and 90°. Special angles are available on request. CONE FACED BODY PART NUMBERS Nozzle Type 70° 80° 90° BUTT WELD ADAPTOR The nozzle inlet can be provided with a butt-weld connection to suit the customer’s existing pipe work sizes in place of the standard thread connection on request. Multiple Nozzle...

Open the catalog to page 13All DELAVAN France catalogs and technical brochures

-

VCN

3 Pages

-

BALL CHECK VALVE

2 Pages

-

Spray Nozzles

28 Pages

-

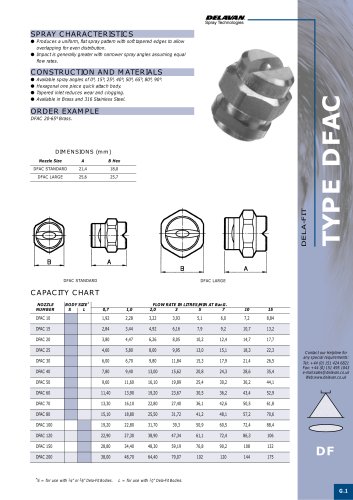

DF BODIES

1 Pages

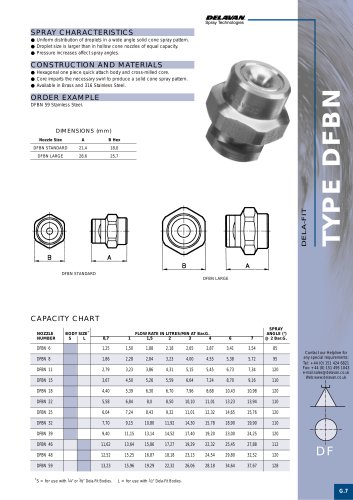

-

DFBN

1 Pages

-

DFBI

1 Pages

-

DFAE

1 Pages

-

DFTJ

1 Pages

-

Solid Cone Section

1 Pages

-

Flat Spray Section Index

1 Pages

-

Cleaning in Place Section

1 Pages

-

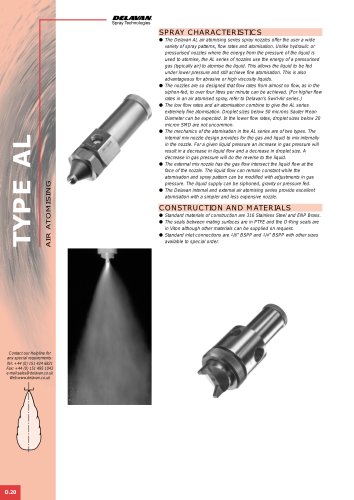

Air Atomising

1 Pages

-

Airless Products

4 Pages

-

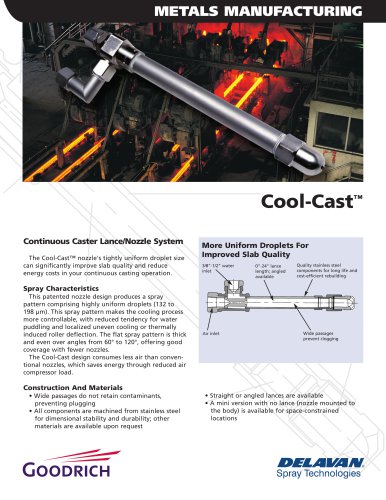

Cool-Cast Nozzles

12 Pages

-

Swirl-Air™ Nozzles

16 Pages

-

Variable Coating Nozzle

4 Pages

-

SDX Spray Drying

16 Pages

-

Pistolets et Lances

1 Pages

-

Filtres de Ligne en T

1 Pages

-

Filtres de Ligne en Y

2 Pages

-

Kwik-Chek

1 Pages

-

Mini-SDX

2 Pages

-

SDX Accessories

1 Pages

-

SDX III

1 Pages

-

SDX V UK

2 Pages

-

CIP 15

1 Pages

-

CIP 21

1 Pages

-

CL7

1 Pages

-

Maxi

2 Pages

-

Mini

2 Pages

-

PU

1 Pages

-

TJ 20G

2 Pages

-

TZ67/79/68

1 Pages

-

TZ74

2 Pages

-

TZ82F/65/75

1 Pages

-

TZ89

1 Pages

-

TZ-67-79-68

1 Pages

-

KN9

1 Pages

-

DWN2019

1 Pages

-

CLFD13

1 Pages

-

CIP2015

1 Pages

-

UC

1 Pages

-

spcon

1 Pages

-

FN

1 Pages

-

BYPASS

1 Pages

-

AJ 150

1 Pages

-

BB

1 Pages

-

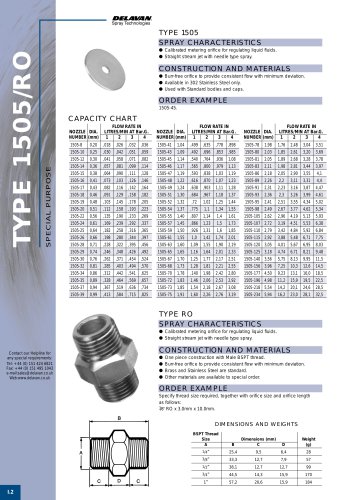

1505-RO

1 Pages

-

RP

1 Pages

-

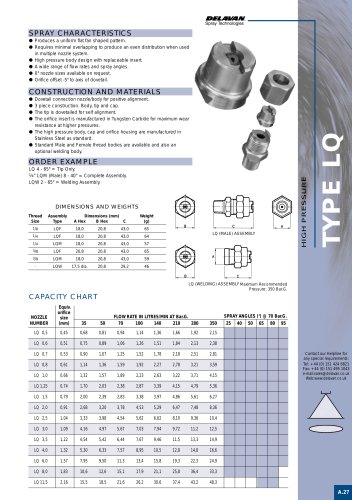

LQ

1 Pages

-

DQ

1 Pages

-

Coolcast

2 Pages

-

Industrie Mettalurgique AI

1 Pages

-

MCN

1 Pages

-

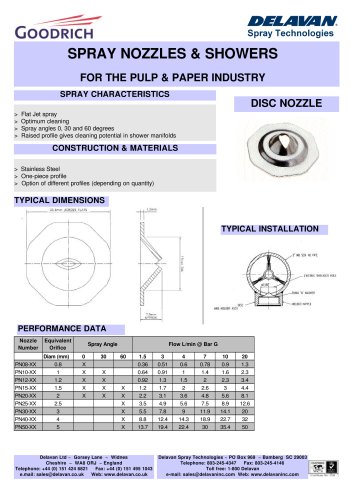

Disc Nozzle

1 Pages

-

Sapphire

1 Pages

-

NBN

1 Pages

-

BC

1 Pages

-

WR

1 Pages

-

HC

1 Pages

-

AG

1 Pages

-

AE

1 Pages

-

DE

1 Pages

-

BZ

1 Pages

-

AQ

1 Pages

-

343

1 Pages

-

AN

1 Pages

-

AC

1 Pages

-

DFAF

1 Pages

-

DFAC

1 Pages

-

DWN19

1 Pages

-

CIP15

1 Pages

-

AIRless Tip

2 Pages

-

AL

6 Pages

-

SDX

2 Pages

-

AIRO

1 Pages

Archived catalogs

-

Buses Airless (Peinture)

4 Pages

-

DELAVAN SWIRL-AIR Nozzles

1 Pages

![Manchons à Souder (HNS) et Adaptateurs]](https://img.directindustry.com/pdf/repository_di/18054/manchons-souder-hns-et-adaptateurs-569997_1mg.jpg)