Website:

DELAVAN France

Website:

DELAVAN France

Group: Goodrich

Catalog excerpts

DELMMN Spray Technologies Product Guide

Open the catalog to page 1

Spray Drying Product Introduction SDX® Spray Dry Nozzles 2 INTRODUCTION SDX® PRODUCT BROCHURE

Open the catalog to page 2

The Delavan Difference ► Durability and Wear Resistance Our nozzles are available in materials that will resist chemical attack such as plastics, ceramics, sintered carbides and various grades of stainless steel. ► Customisation Custom spray characteristics to meet a variety of application needs; such as droplet and particle size, spray angle, flow variation and liquid properties. ► Versatility 3 swirl chamber designs with orifice discs from 0.4mm (0.016”)-6.4mm (0.252”). The large number of swirl chamber and orifice sizes provide customers with more options and can be paired in a variety...

Open the catalog to page 3

Spray Drying Technical Information SDX® Spray Dry Nozzles The Critical Factors That Affect Spray Quality The Atomiser Delavan recognises that at the ‘heart’ of any spray dryer is the atomiser, small in size, big in importance. Therefore installing the right atomiser is an essential step to ensuring spray drying success. The atomiser must fulfil several important functions: 1. It must disperse the feed material into small droplets, which should be well distributed within the dryer and mixed thoroughly with the hot gas 2. The size of the droplets produced must be compatible with the required...

Open the catalog to page 4

Liquid Properties The properties of the feed stock are directly related to the finished particle size. Therefore density, viscosity, percentage solids, abrasive awareness and any other characteristics all need to be considered. The liquid properties should be established at the temperature corresponding to the liquid in the nozzle. Feed stocks are often sprayed at elevated temperatures to decrease viscosity, thereby improving atomisation. The effect of each liquid property on droplet size is usually established by actual test, however Delavan’s field experience shows that these effects can...

Open the catalog to page 5

Spray Drying Product Range SDX® Spray Dry Nozzles Product Overview Delavan Spray Technologies has been the leading innovator and supplier of atomising nozzles for the spray dry industry for more than four decades. This tradition started with the original SDX® Nozzle and continues with the latest SDX® family of nozzles. This product line, specifically designed for the spray drying industry, includes five centrifugal pressure nozzles: the Mini SDX®, Compact SDX®, SDX®, SDX® III and SDX® V. Each of these five products is built on Delavan’s unique single inlet spiral swirl chamber design and...

Open the catalog to page 6

Mini SDX® Nozzle The Mini SDX® is a low-flow, easy to assemble nozzle, offers the same performance and technology as our larger SDX® products, but for lower capacity applications. Hand tighten assembly with a maximum operating pressure of 345 BAR/5000 PSI and temperature of 149° C/300° F. Maximum operating temperature of 149° C/300° F. Mini SDX® Assembly Description and Part Numbers Description Part Number Material (A) Body A329320020 Stainless Steel (B) Orifice Disc A00902-XXX* Tungsten Carbide (C) Swirl Chamber See Swirl Chamber Chart (E) 1/4 NPTF Adaptor...

Open the catalog to page 7

SDX® Nozzle The SDX® is a classic eight part construction nozzle made from Stainless Steel and would typically be used for high pressure and high temperature applications. Torque tighten assembly with a maximum operating pressure of 482 BAR/7000 PSI. Maximum operating temperature of 538° C/1000° F (with metal seals). SDX® Assembly Description and Part Numbers Description Part Number Material SDX® Swirl Chamber/End Plate Part Numbers Swirl Chamber/Endplate Swirl Chamber Only Ref Tungsten Carbide Tungsten Carbide HSS (A) Body Stainless Steel Hard Fibre Stainless Steel (D) Swirl Chamber...

Open the catalog to page 8

SDX® III Nozzle The SDX III® is a six part nozzle, of which the wear parts (orifice and swirl chamber) are interchangeable with the ‘Classic’ SDX®. It features O-Rings for sealing so can be hand tightened, requiring no tools at all. Hand tighten assembly with a maximum operating pressure of 345 BAR/5000 PSI. A further derivative capable of operation of 700 BAR/10150 PSI. Maximum operating temperature of 149° C/300° F. SDX® III Assembly Description and Part Numbers SDX® III Swirl Chamber/End Plate Part Numbers Swirl Chamber/Endplate Swirl Chamber Only Description Part...

Open the catalog to page 9

SDX® V Nozzle The SDX® V features eight part construction and is the world’s most user-friendly spray drying nozzle featuring an improved wear life/performance and effortless maintenance for the lowest cost of ownership. Hand tighten assembly with a maximum operating pressure of 345 BAR/5000 PSI and temperature of 149° C/300° F. Maximum operating temperature of 149° C/300° F. SDX® V Assembly Description and Part Numbers Description Part Number MaterialSDX® V Swirl Chamber Part Numbers Ref Standard1 Flat Back1 Open1 Crown Retainer1 SDX® Adaptor W19636 Stainless Steel SDX®...

Open the catalog to page 10

SDX® V Swirl Chambers Delavan has introduced an alternative design of Swirl Chamber especially for the SDX® V nozzle. The end plate is no longer integrated but is supplied as a separate component. This new option addresses occasions where increased wear on the bottom of the standard chamber occurs, caused by cavitation or abrasive particles. In certain circumstances, the bottom of the Swirl Chamber wears out before the walls, or the inlet throat. With the new design, the separate end plate can be replaced and the ‘open’ Swirl Chamber can be reused. There is also the option to use end plates...

Open the catalog to page 11

Compact SDX® Nozzle The Compact SDX® is a new and improved nozzle, featuring easy to assemble, longer lasting parts. It mimics the Mini SDX® in size but has a higher flow range with more spray angles. Hand tighten assembly with a maximum operating pressure of 345 BAR/5000 PSI and temperature of 149° C/300° F. Maximum operating temperature of 149° C/300° F. Removal Tool Part No. W203080012. For the removal of Compact SDX® Swirl Chambers and Orifice Discs. ^Compact SDX® Assembly Description and Part Numbers Stainless Steel Tungsten Carbide Tungsten Carbide Tungsten Carbide Tungsten Carbide...

Open the catalog to page 12All DELAVAN France catalogs and technical brochures

-

VCN

3 Pages

-

BALL CHECK VALVE

2 Pages

-

Spray Nozzles

28 Pages

-

SDX Spray Drying

16 Pages

-

DF BODIES

1 Pages

-

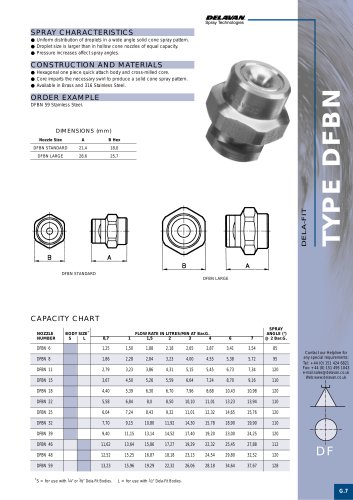

DFBN

1 Pages

-

DFBI

1 Pages

-

DFAE

1 Pages

-

DFTJ

1 Pages

-

Solid Cone Section

1 Pages

-

Flat Spray Section Index

1 Pages

-

Cleaning in Place Section

1 Pages

-

Air Atomising

1 Pages

-

Airless Products

4 Pages

-

Cool-Cast Nozzles

12 Pages

-

Swirl-Air™ Nozzles

16 Pages

-

Variable Coating Nozzle

4 Pages

-

Pistolets et Lances

1 Pages

-

Filtres de Ligne en T

1 Pages

-

Filtres de Ligne en Y

2 Pages

-

Kwik-Chek

1 Pages

-

Mini-SDX

2 Pages

-

SDX Accessories

1 Pages

-

SDX III

1 Pages

-

SDX V UK

2 Pages

-

CIP 15

1 Pages

-

CIP 21

1 Pages

-

CL7

1 Pages

-

Maxi

2 Pages

-

Mini

2 Pages

-

PU

1 Pages

-

TJ 20G

2 Pages

-

TZ67/79/68

1 Pages

-

TZ74

2 Pages

-

TZ82F/65/75

1 Pages

-

TZ89

1 Pages

-

TZ-67-79-68

1 Pages

-

KN9

1 Pages

-

DWN2019

1 Pages

-

CLFD13

1 Pages

-

CIP2015

1 Pages

-

UC

1 Pages

-

spcon

1 Pages

-

FN

1 Pages

-

BYPASS

1 Pages

-

AJ 150

1 Pages

-

BB

1 Pages

-

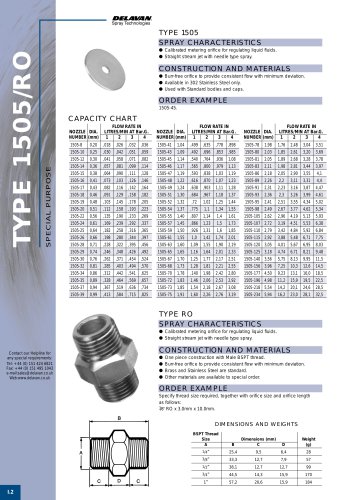

1505-RO

1 Pages

-

RP

1 Pages

-

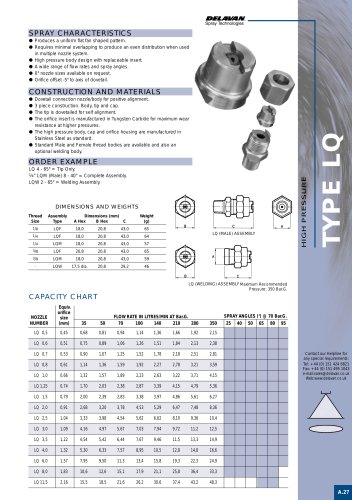

LQ

1 Pages

-

DQ

1 Pages

-

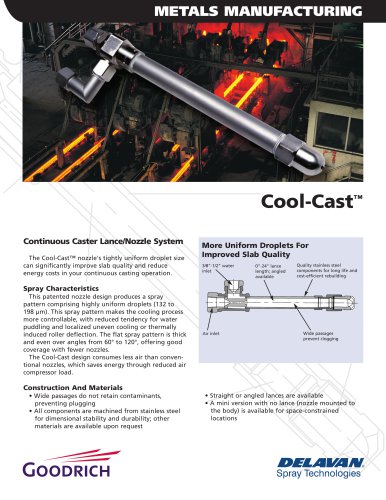

Coolcast

2 Pages

-

Industrie Mettalurgique AI

1 Pages

-

MCN

1 Pages

-

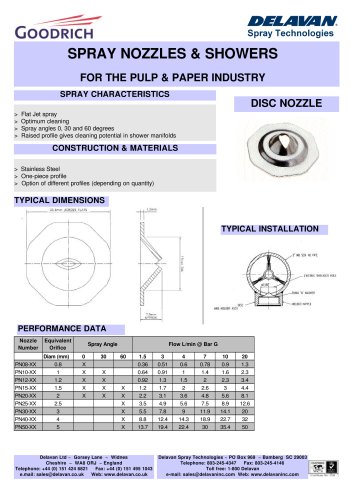

Disc Nozzle

1 Pages

-

Sapphire

1 Pages

-

NBN

1 Pages

-

BC

1 Pages

-

WR

1 Pages

-

HC

1 Pages

-

AG

1 Pages

-

AE

1 Pages

-

DE

1 Pages

-

BZ

1 Pages

-

AQ

1 Pages

-

343

1 Pages

-

AN

1 Pages

-

AC

1 Pages

-

DFAF

1 Pages

-

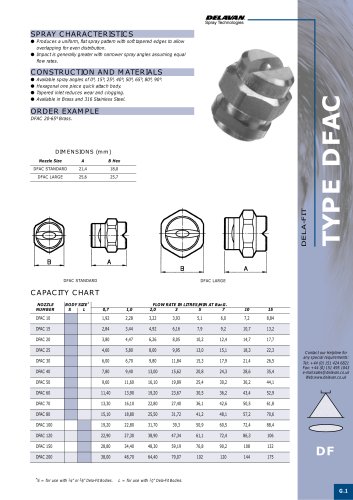

DFAC

1 Pages

-

DWN19

1 Pages

-

CIP15

1 Pages

-

AIRless Tip

2 Pages

-

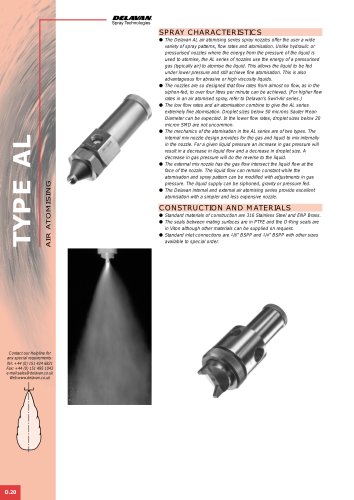

AL

6 Pages

-

SDX

2 Pages

-

AIRO

1 Pages

Archived catalogs

-

Buses Airless (Peinture)

4 Pages

-

DELAVAN SWIRL-AIR Nozzles

1 Pages

![Manchons à Souder (HNS) et Adaptateurs]](https://img.directindustry.com/pdf/repository_di/18054/manchons-souder-hns-et-adaptateurs-569997_1mg.jpg)