Website:

DELAVAN France

Website:

DELAVAN France

Group: Goodrich

Catalog excerpts

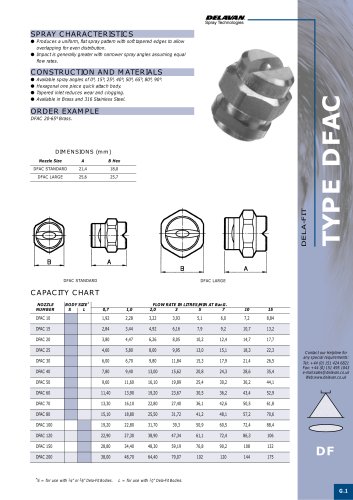

q The SDX series nozzles produce a hollow cone spray pattern with uniform particle size distribution even at low operating pressures. q Flow rates are certified to be within ±5% of rated capacity at 65 Bar.G. and within ±5º of rated spray angle when tested with water. q Unique, patented single inlet spiral swirl chamber offers increased nozzle life, improved product uniformity, density or solubility. q Minimal friction due to nozzle design permitting 10-20% lower operating pressure than conventional slotted distributor nozzle for equivalent atomisation quality. q Extended pump life due to lower operating pressure. q Reduction in fine particles is possible due to lower pressure requirements. SPRAY DRYING SPRAY CHARACTERISTICS q Six part construction (see part and material list below). q O-ring seals allow assembly and disassembly without tools. q Body and adaptors are produced from hexagon barstock with other materials in round bar with flats. q Nozzle bodies and adaptors are available in 316 Stainless Steel. Other materials are available on special request. q Orifice discs are easily removable and are available in Tungsten Carbide, Chrome Carbide and Ceramic. q Swirl chambers are standard in Tungsten Carbide, Hardened Stainless Steel or Ceramic. q End plates are available in Tungsten Carbide and Ceramic. q Combined swirl chamber/end plate is available in Tungsten Carbide only. q O-Rings are in Silicone or Viton. Max. Design Pressure: 350 Bar.G. Max. Design Temperature: 150ºC. ORDER EXAMPLE Please indicate all component parts and materials when ordering. WEIGHTS Assembly Size 95 (VARIES WITH SWIRL CHAMBER) COMPONENT PARTS, MATERIALS AND WEIGHTS Description Orifice O-Ring Silicone Viton Orifice Disc Tungsten Carbide Chrome Carbide Ceramic Swirl Chamber Swirl Chamber Swirl Chamber Swirl Chamber with End Plate Combined Hardened Stainless Steel Tungsten Carbide Ceramic Tungsten Carbide Tungsten Carbide Ceramic Adaptor O-Ring Silicone Viton BSPT Female Adaptor 3⁄8” BSPT Female Adaptor 1⁄2” BSPT Female Adaptor 3⁄4” BSPT Female Adaptor Contact our Helpline for any special requirements: Tel: +44 (0) 151 424 6821 Fax: +44 (0) 151 495 1043 e-mail:sales@delavan.co.uk Web:www.delavan.co.uk ORIFICE SEAL ORIFICE DISC SWIRL CHAMBERS ADAPTOR SEAL * Specify orifice size and swirl chamber suffix from capacity chart. ** End plate not required with W01380 swirl chamber.

Open the catalog to page 1All DELAVAN France catalogs and technical brochures

-

VCN

3 Pages

-

BALL CHECK VALVE

2 Pages

-

Spray Nozzles

28 Pages

-

SDX Spray Drying

16 Pages

-

DF BODIES

1 Pages

-

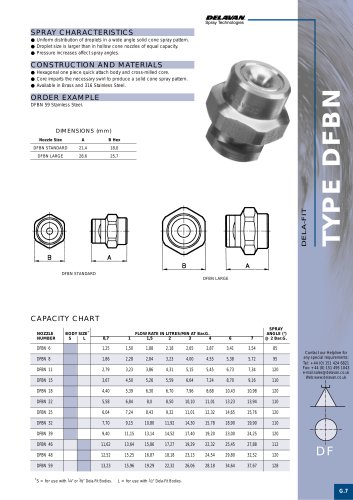

DFBN

1 Pages

-

DFBI

1 Pages

-

DFAE

1 Pages

-

DFTJ

1 Pages

-

Solid Cone Section

1 Pages

-

Flat Spray Section Index

1 Pages

-

Cleaning in Place Section

1 Pages

-

Air Atomising

1 Pages

-

Airless Products

4 Pages

-

Cool-Cast Nozzles

12 Pages

-

Swirl-Air™ Nozzles

16 Pages

-

Variable Coating Nozzle

4 Pages

-

SDX Spray Drying

16 Pages

-

Pistolets et Lances

1 Pages

-

Filtres de Ligne en T

1 Pages

-

Filtres de Ligne en Y

2 Pages

-

Kwik-Chek

1 Pages

-

Mini-SDX

2 Pages

-

SDX Accessories

1 Pages

-

SDX V UK

2 Pages

-

CIP 15

1 Pages

-

CIP 21

1 Pages

-

CL7

1 Pages

-

Maxi

2 Pages

-

Mini

2 Pages

-

PU

1 Pages

-

TJ 20G

2 Pages

-

TZ67/79/68

1 Pages

-

TZ74

2 Pages

-

TZ82F/65/75

1 Pages

-

TZ89

1 Pages

-

TZ-67-79-68

1 Pages

-

KN9

1 Pages

-

DWN2019

1 Pages

-

CLFD13

1 Pages

-

CIP2015

1 Pages

-

UC

1 Pages

-

spcon

1 Pages

-

FN

1 Pages

-

BYPASS

1 Pages

-

AJ 150

1 Pages

-

BB

1 Pages

-

1505-RO

1 Pages

-

RP

1 Pages

-

LQ

1 Pages

-

DQ

1 Pages

-

Coolcast

2 Pages

-

Industrie Mettalurgique AI

1 Pages

-

MCN

1 Pages

-

Disc Nozzle

1 Pages

-

Sapphire

1 Pages

-

NBN

1 Pages

-

BC

1 Pages

-

WR

1 Pages

-

HC

1 Pages

-

AG

1 Pages

-

AE

1 Pages

-

DE

1 Pages

-

BZ

1 Pages

-

AQ

1 Pages

-

343

1 Pages

-

AN

1 Pages

-

AC

1 Pages

-

DFAF

1 Pages

-

DFAC

1 Pages

-

DWN19

1 Pages

-

CIP15

1 Pages

-

AIRless Tip

2 Pages

-

AL

6 Pages

-

SDX

2 Pages

-

AIRO

1 Pages

Archived catalogs

-

Buses Airless (Peinture)

4 Pages

-

DELAVAN SWIRL-AIR Nozzles

1 Pages

![Manchons à Souder (HNS) et Adaptateurs]](https://img.directindustry.com/pdf/repository_di/18054/manchons-souder-hns-et-adaptateurs-569997_1mg.jpg)