Website:

DELAVAN France

Website:

DELAVAN France

Group: Goodrich

Catalog excerpts

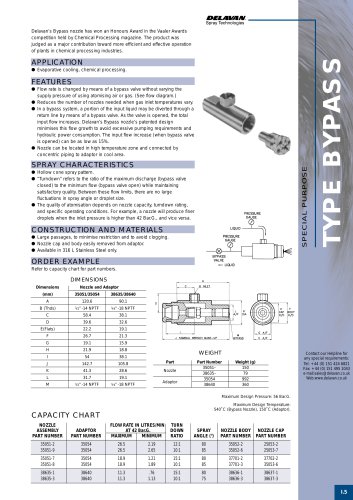

APPLICATION q Evaporative cooling, chemical processing. FEATURES q Flow rate is changed by means of a bypass valve without varying the supply pressure of using atomising air or gas. (See flow diagram.) q Reduces the number of nozzles needed when gas inlet temperatures vary. q In a bypass system, a portion of the input liquid may be diverted through a return line by means of a bypass valve. As the valve is opened, the total input flow increases. Delavan’s Bypass nozzle’s patented design minimises this flow growth to avoid excessive pumping requirements and hydraulic power consumption. The input flow increase (when bypass valve is opened) can be as low as 15%. q Nozzle can be located in high temperature zone and connected by concentric piping to adaptor in cool area. SPECIAL PURPOSE SPRAY CHARACTERISTICS q Hollow cone spray pattern. q “Turndown” refers to the ratio of the maximum discharge (bypass valve closed) to the minimum flow (bypass valve open) while maintaining satisfactory quality. Between these flow limits, there are no large fluctuations in spray angle or droplet size. q The quality of atomisation depends on nozzle capacity, turndown rating, and specific operating conditions. For example, a nozzle will produce finer droplets when the inlet pressure is higher than 42 Bar.G., and vice versa. CONSTRUCTION AND MATERIALS q Large passages, to minimise restriction and to avoid clogging. q Nozzle cap and body easily removed from adaptor. q Available in 316 L Stainless Steel only. TYPE BYPASS Delavan’s Bypass nozzle has won an Honours Award in the Vaaler Awards competition held by Chemical Processing magazine. The product was judged as a major contribution toward more efficient and effective operation of plants in chemical processing industries. ORDER EXAMPLE Refer to capacity chart for part numbers. DIMENSIONS Dimensions Contact our Helpline for any special requirements: Tel: +44 (0) 151 424 6821 Fax: +44 (0) 151 495 1043 e-mail:sales@delavan.co.uk Web:www.delavan.co.uk Maximum Design Pressure: 56 Bar.G. Maximum Design Temperature: 540˚C (Bypass Nozzle), 150˚C (Adaptor). CAPACITY CHART NOZZLE ASSEMBLY PART NUMBER ADAPTOR PART NUMBER FLOW RATE IN LITRES/MIN AT 42 Bar.G. MAXIMUM MINIMUM TURN DOWN RATIO NOZZLE BODY PART NUMBER NOZZLE CAP PART NUMBER

Open the catalog to page 1All DELAVAN France catalogs and technical brochures

-

VCN

3 Pages

-

BALL CHECK VALVE

2 Pages

-

Spray Nozzles

28 Pages

-

SDX Spray Drying

16 Pages

-

DF BODIES

1 Pages

-

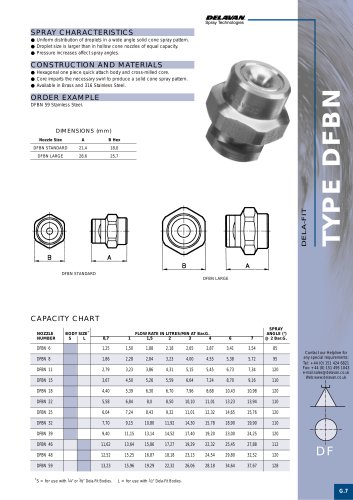

DFBN

1 Pages

-

DFBI

1 Pages

-

DFAE

1 Pages

-

DFTJ

1 Pages

-

Solid Cone Section

1 Pages

-

Flat Spray Section Index

1 Pages

-

Cleaning in Place Section

1 Pages

-

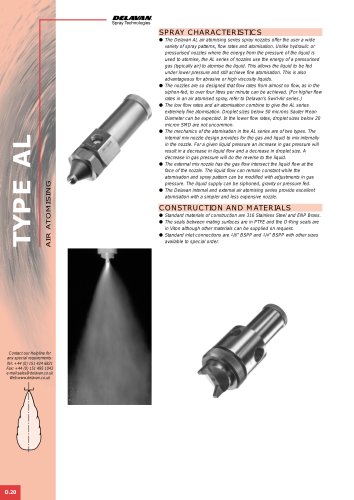

Air Atomising

1 Pages

-

Airless Products

4 Pages

-

Cool-Cast Nozzles

12 Pages

-

Swirl-Air™ Nozzles

16 Pages

-

Variable Coating Nozzle

4 Pages

-

SDX Spray Drying

16 Pages

-

Pistolets et Lances

1 Pages

-

Filtres de Ligne en T

1 Pages

-

Filtres de Ligne en Y

2 Pages

-

Kwik-Chek

1 Pages

-

Mini-SDX

2 Pages

-

SDX Accessories

1 Pages

-

SDX III

1 Pages

-

SDX V UK

2 Pages

-

CIP 15

1 Pages

-

CIP 21

1 Pages

-

CL7

1 Pages

-

Maxi

2 Pages

-

Mini

2 Pages

-

PU

1 Pages

-

TJ 20G

2 Pages

-

TZ67/79/68

1 Pages

-

TZ74

2 Pages

-

TZ82F/65/75

1 Pages

-

TZ89

1 Pages

-

TZ-67-79-68

1 Pages

-

KN9

1 Pages

-

DWN2019

1 Pages

-

CLFD13

1 Pages

-

CIP2015

1 Pages

-

UC

1 Pages

-

spcon

1 Pages

-

FN

1 Pages

-

AJ 150

1 Pages

-

BB

1 Pages

-

1505-RO

1 Pages

-

RP

1 Pages

-

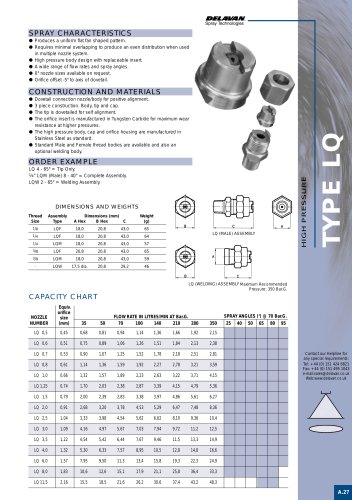

LQ

1 Pages

-

DQ

1 Pages

-

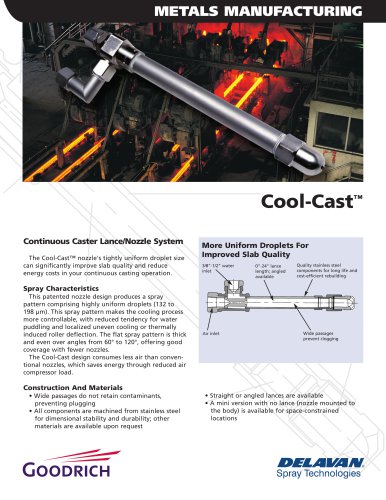

Coolcast

2 Pages

-

Industrie Mettalurgique AI

1 Pages

-

MCN

1 Pages

-

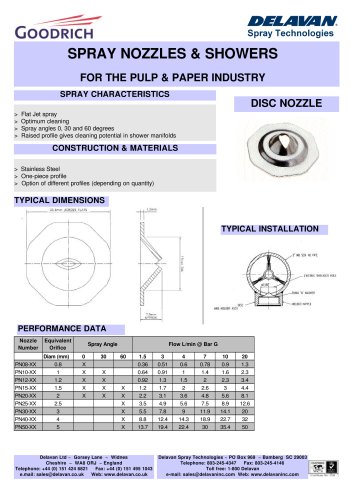

Disc Nozzle

1 Pages

-

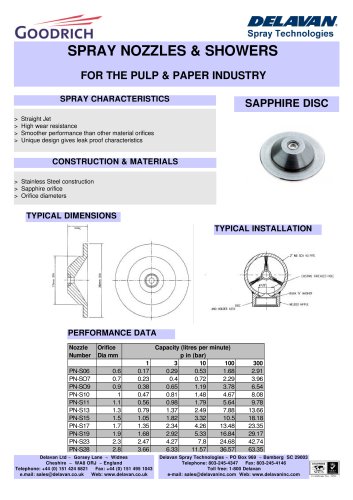

Sapphire

1 Pages

-

NBN

1 Pages

-

BC

1 Pages

-

WR

1 Pages

-

HC

1 Pages

-

AG

1 Pages

-

AE

1 Pages

-

DE

1 Pages

-

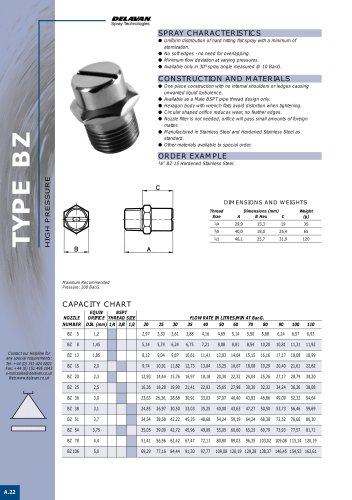

BZ

1 Pages

-

AQ

1 Pages

-

343

1 Pages

-

AN

1 Pages

-

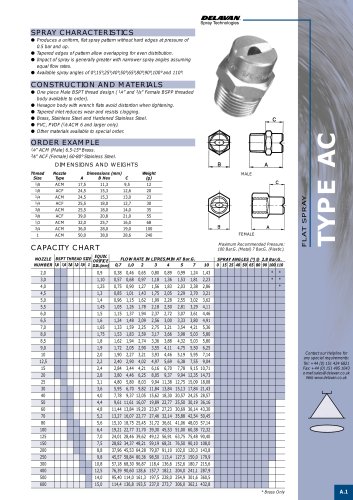

AC

1 Pages

-

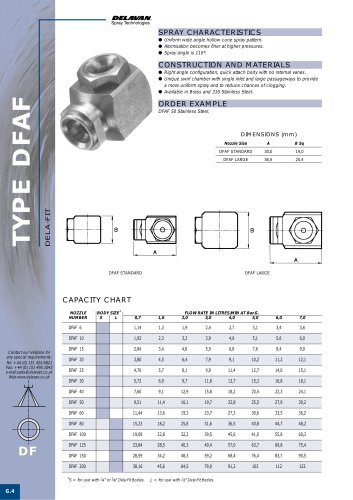

DFAF

1 Pages

-

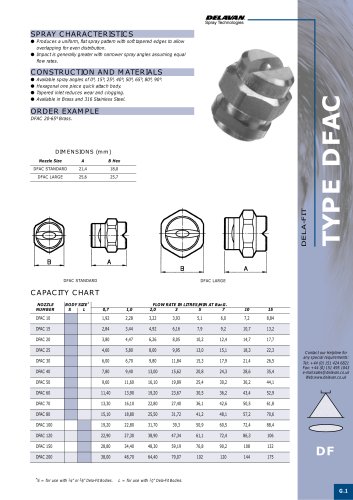

DFAC

1 Pages

-

DWN19

1 Pages

-

CIP15

1 Pages

-

AIRless Tip

2 Pages

-

AL

6 Pages

-

SDX

2 Pages

-

AIRO

1 Pages

Archived catalogs

-

Buses Airless (Peinture)

4 Pages

-

DELAVAN SWIRL-AIR Nozzles

1 Pages

![Manchons à Souder (HNS) et Adaptateurs]](https://img.directindustry.com/pdf/repository_di/18054/manchons-souder-hns-et-adaptateurs-569997_1mg.jpg)