Website:

DELAVAN France

Website:

DELAVAN France

Group: Goodrich

Catalog excerpts

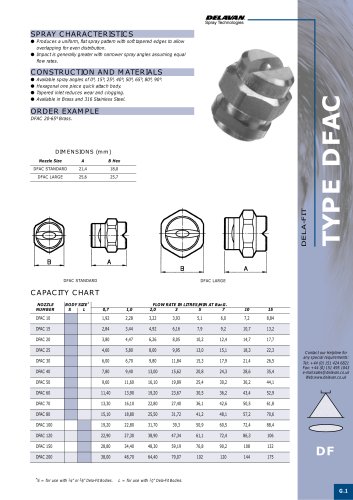

APPLICATIONS q Agitation and mixing of liquids containing solid suspensions. q Cataphoresis plants. q Stainless Steel units ideal for steam heating of liquid in tanks where uniform heat distribution over a large area is required. High efficiency. Wide range of flow capacities. Outstanding resistance to erosion/corrosion. Tapered inlet reduces wear and resists clogging. High velocity jet stream for maximum agitation/mixing. Typical turnover ratio of 3:1. q Produces a high velocity straight jet. q Induces the surrounding liquid into the jet stream. CONSTRUCTION AND MATERIALS SPECIAL PURPOSE q One piece design with no internal components. q Available with 3⁄8”, 1⁄2” and 3⁄4” Male BSPT thread. q Available in 316 Stainless Steel or Glass filled Polypropylene (Polyglass). BB 100 Stainless Steel. BB 250 Polyglass. MOULDED EDUCTOR DIMENSIONS AND WEIGHTS POLYGLASS 316 STAINLESS STEEL Weight A B C (g) THREAD Size SPRAY CHARACTERISTICS METAL EDUCTOR Maximum Recommended Pressure: 10 Bar.G.(Polyglass), 35 Bar.G.(Stainless Steel). Maximum Recommended Temperature: 75˚C (Polyglass), 500˚C (Stainless Steel). CAPACITY CHART NOZZLE NUMBER APPROX. ORIFICE SIZE (mm) BSPT THREAD SIZE 3/8 1/2 3/4 FLOW RATE IN LITRES/MIN AT Bar.G. ,7 Turnover Ratio 1,5– 4,0 Bar.G. Contact our Helpline for any special requirements: Tel: +44 (0) 151 424 6821 Fax: +44 (0) 151 495 1043 e-mail:sales@delavan.co.uk Web:www.delavan.co.uk LARGER SIZES ARE AVAILABLE - CONTACT OUR CUSTOMER SERVICES DEPARTMENT TANK HEATING CHART STEAM PRESSURE Bar.G. TIME IN MINUTES TO HEAT 300 LITRES OF WATER AT VARIOUS STEAM PRESSURES 0,35 0,7 1 2 3 4 5 11 TEMPERATURE RISE This chart is based on using a single 1/2” BB 100 Stainless Steel nozzle with a 6,4mm orifice.

Open the catalog to page 1All DELAVAN France catalogs and technical brochures

-

VCN

3 Pages

-

BALL CHECK VALVE

2 Pages

-

Spray Nozzles

28 Pages

-

SDX Spray Drying

16 Pages

-

DF BODIES

1 Pages

-

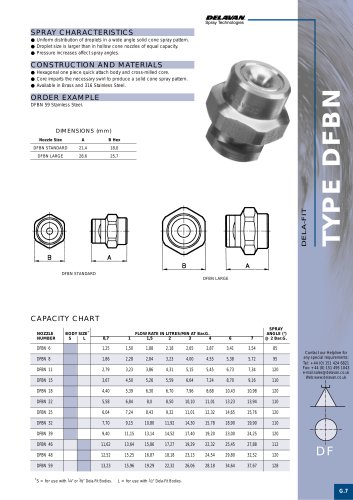

DFBN

1 Pages

-

DFBI

1 Pages

-

DFAE

1 Pages

-

DFTJ

1 Pages

-

Solid Cone Section

1 Pages

-

Flat Spray Section Index

1 Pages

-

Cleaning in Place Section

1 Pages

-

Air Atomising

1 Pages

-

Airless Products

4 Pages

-

Cool-Cast Nozzles

12 Pages

-

Swirl-Air™ Nozzles

16 Pages

-

Variable Coating Nozzle

4 Pages

-

SDX Spray Drying

16 Pages

-

Pistolets et Lances

1 Pages

-

Filtres de Ligne en T

1 Pages

-

Filtres de Ligne en Y

2 Pages

-

Kwik-Chek

1 Pages

-

Mini-SDX

2 Pages

-

SDX Accessories

1 Pages

-

SDX III

1 Pages

-

SDX V UK

2 Pages

-

CIP 15

1 Pages

-

CIP 21

1 Pages

-

CL7

1 Pages

-

Maxi

2 Pages

-

Mini

2 Pages

-

PU

1 Pages

-

TJ 20G

2 Pages

-

TZ67/79/68

1 Pages

-

TZ74

2 Pages

-

TZ82F/65/75

1 Pages

-

TZ89

1 Pages

-

TZ-67-79-68

1 Pages

-

KN9

1 Pages

-

DWN2019

1 Pages

-

CLFD13

1 Pages

-

CIP2015

1 Pages

-

UC

1 Pages

-

spcon

1 Pages

-

FN

1 Pages

-

BYPASS

1 Pages

-

AJ 150

1 Pages

-

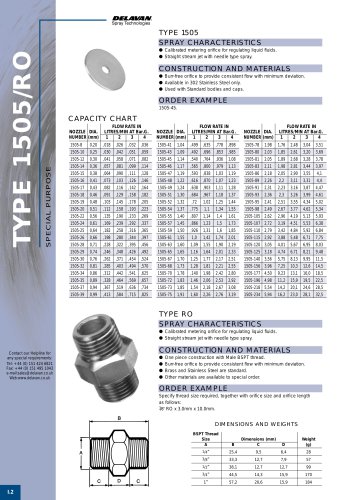

1505-RO

1 Pages

-

RP

1 Pages

-

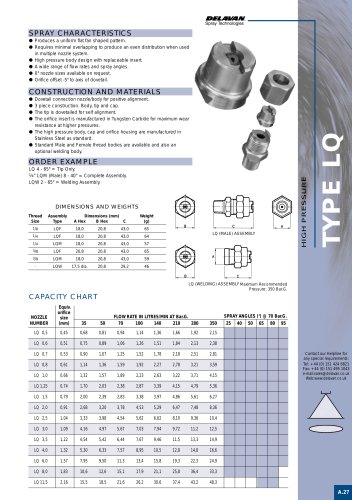

LQ

1 Pages

-

DQ

1 Pages

-

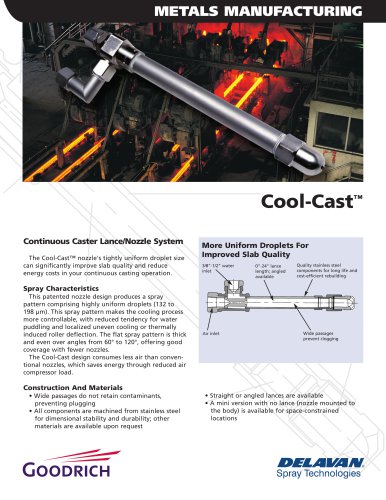

Coolcast

2 Pages

-

Industrie Mettalurgique AI

1 Pages

-

MCN

1 Pages

-

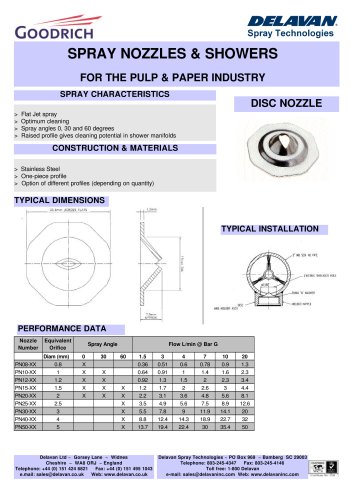

Disc Nozzle

1 Pages

-

Sapphire

1 Pages

-

NBN

1 Pages

-

BC

1 Pages

-

WR

1 Pages

-

HC

1 Pages

-

AG

1 Pages

-

AE

1 Pages

-

DE

1 Pages

-

BZ

1 Pages

-

AQ

1 Pages

-

343

1 Pages

-

AN

1 Pages

-

AC

1 Pages

-

DFAF

1 Pages

-

DFAC

1 Pages

-

DWN19

1 Pages

-

CIP15

1 Pages

-

AIRless Tip

2 Pages

-

AL

6 Pages

-

SDX

2 Pages

-

AIRO

1 Pages

Archived catalogs

-

Buses Airless (Peinture)

4 Pages

-

DELAVAN SWIRL-AIR Nozzles

1 Pages

![Manchons à Souder (HNS) et Adaptateurs]](https://img.directindustry.com/pdf/repository_di/18054/manchons-souder-hns-et-adaptateurs-569997_1mg.jpg)