Catalog excerpts

CNC Drill Grinder and Sharpener Operating Instructions

Open the catalog to page 1

Safety Instructions •WARNING! Read and understand all instructions. Failure to follow all instructions listed may result in electric shock, fire and/or serious injury. Installation/Assembly Carefully unpack the sharpener. Check to see that no damage has occurred in shipment. Check all packing materials to be sure that all parts are present. Refer to the packing list. •DANGER! Electrical shock can kill! Read, understand and follow ALL safety instructions. •WARNING! Connect to properly wired (110V or 230V, as applicable) outlet, or electrical shock may occur. •CAUTION! Do not operate the...

Open the catalog to page 4

• Replace damaged or worn cord immediately. Call Darex® Technical Support for assistance. • Grounded, cord-connected tools intended for use on a supply circuit having a nominal rating less than 150 volts: This sharpener is intended for use on a circuit that has an outlet that looks like the one illustrated in Figure B, below. The tool has a grounding plug that looks like the plug illustrated in Figure A. A temporary adapter which looks like the adapter illustrated in Figures C and D, may be used (except in Canada) to connect this plug to a 2-pole receptacle as shown in Figure B if a...

Open the catalog to page 5

•CAUTION! Keep power tools and work space clean for best performance and safety. • Maintain sharpener with care. Many accidents are caused by poorly maintained power tools. Follow instructions for lubricating and changing accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the sharpener’s operation. If damaged, have the sharpener repaired before use. Keep unit dry, clean and free from oil and grease. • Do not let sharpening debris accumulate on, in, or around the tool. Accumulated fine metal sharpening debris can be very...

Open the catalog to page 6

Specific Safety Rules: •WARNING! ALWAYS use proper safety glasses. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if operation is dusty. ALWAYS wear certified safety equipment: • ANSI Z87.1 eye protection (CAN/CSA Z94.3) • ANSI 512.6 (53.19) hearing protection • NIO5H/OSHA respiratory protection •WARNING! Use of this tool can generate and/or disperse dust, which may cause serious permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body. •WARNING! This...

Open the catalog to page 7

XPS-16+ Specifications Wheel Guard Cover Drill Holder Emergency Stop Cycle Start Cycle Stop LCD Touch Screen Environmental Door Grind Wheel Storage Grind Wheel XPS-16+ Automatic Measurement Features Your XPS-16+ has many features so carefully designed and engineered that you may not even be aware of their uniqueness. Once the cycle start button has been pressed, your Darex XPS16+ begins taking measurements of the drill on the way to the grinding wheel. It locates the end of the drill, calculates diameter, locates and positions the cutting edge, determines web thickness, identifies initial...

Open the catalog to page 8

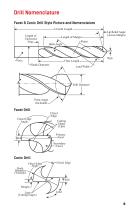

Drill Nomenclature Facet & Conic Drill Style Picture and Nomenclature Overall Length Length of Uncleared Flute Length of Margin Flutes Helix Angle Flute Length Shank Diameter Lip Relief Angle (Across Margin) Land Width Drill Diameter Point Angle (Included) Facet Drill Chisel Edge Angle Chisel Edge Cutting Edges (Lips) Primary Facet Secondary Facet Conic Drill Body Diameter Clearance Chisel Edge Angle Chisel Edge Web Margin Lips (Cutting Edges)

Open the catalog to page 9

Point Split & Relief Diagrams Depth of Split Diagram Center of Split Diagram Past Center To Center Below Center Past Center Split Angle Diagram Past Center Below Center Relief Correct Relief Excessive Relief Negative Relief Below Cente

Open the catalog to page 10

Machine Axis Definition X Axis: A crossfeed axis which moves the grinding wheel sideways. C Axis: A rotate stage which turns the drill bit about its axis. A Axis: A swing stage which tilts the drill bit up and down at the rear. Z Axis: An infeed axis which positions the drill bit closer to or further from the grinding wheel.

Open the catalog to page 11

Touch Screen Icon Reference Cycle Start (Green) Web Thickness Detection Screen Cycle Stop (Amber) Point Angle Selection Minimal Material Removal Hone primary cutting edge after sharpening Primary and secondary cutting edge hone Rotate drill in hone brush Mid-range Material Removal No Split or No Grind Selected Maximum Material Removal Standard Split Point Diameter Detection Auto Or Manual Radius Split Point Tools Button To Access Second Page

Open the catalog to page 12

Curser Down Relief Selection Screen Curser Up Page Down High Speed Steel Or Cobalt Material Selector Carbide Material Move Sharpener Axis In A Negative Direction File Management Sharpener (Inches) Active Move Sharpener Axis In A Positive Direction Hone Time Adjustment Honing Wheel Offset Adjustment Honing Brush Edge Offset Adjustment - X Axis Advance Selection Honing Brush Face Offset Adjustment - Z Axis Auto Mode Selector Wheel Position Offset Manual Align Mode Selector Wheel Edge Offset Adjustment - X Axis Wheel Face Offset Adjustment - Z Axis Split Point Offset Adjustment Position Stage...

Open the catalog to page 13

Touch Screen Details Main Operating Screen The screen shot this shows what will be depicted on the touch screen once power has been applied to the XPS-16+. Press the [check] in order to initialize the XPS-16+. The Environmental Door has to be closed for the machine to execute initialization. This is the Main Operating Screen. Starting left to right and top to bottom, each icon will be explained in detail. Point Angle Adjustment Press the [Point Angle] icon. A keyboard will appear. Type in the point angle of the drill you wish to grind. The acceptable range is 90°-150° for conic ground...

Open the catalog to page 14

Note: If the point angle entered is beyond the machines limits, the XPS-16+ will default to the nearest value the machine is capable of grinding. If the desired grind angle is less than 115°, the XPS-16+ will automatically prompt the operator for additional information. The programming of the [Web Thickness] and [Advance] features will be covered in the [Web Detection] section of the User Guide. Material Removal Icon Each touch will change between three options: Range .015 - .020” (conic only) • Factory default is “MIN”. • Facet drill point is limited to “MIN” & “MID”. Tip: Use “MIN” when...

Open the catalog to page 15All Darex catalogs and technical brochures

-

Large Drill Attachment LEX050

19 Pages

-

V-390 Drill Sharpener

20 Pages