Website:

DANOBATGROUP

Website:

DANOBATGROUP

Group: DANOBATGROUP

Catalog excerpts

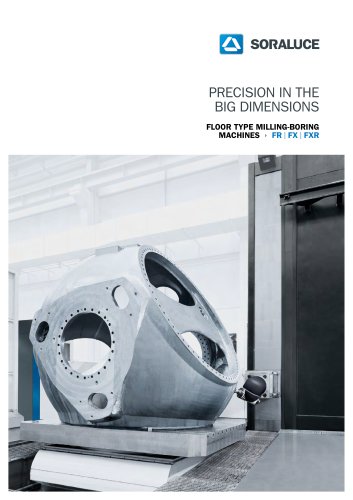

SORALUCE PRECISION IN THE BIG DIMENSIONS FLOOR TYPE MILLING-BORING MACHINES > FR | FX | FXR

Open the catalog to page 1

MACHINES WITH GREAT DIMENSIONS AND MACHINING CAPACITY The new generation of SORALUCE FR - FX - FXR is the expression of SORALUCE's values: reliability, precision and competitiveness. Within these concepts, customers find huge improvements in maintenance, ergonomics, high dynamics and safety in the work environment. The SORALUCE FR - FX - FXR floor type milling-boring centres are multi-purpose milling- boring machines, offering high versatility and productivity for large component machining. Its rigid stable design provides the highest precision and productivity benefits when machining large...

Open the catalog to page 3

DESIGN The design of the machine structure and dimensions have been optimised by an analysis based on “Finite Element Method” (FEM) simulation technique, optimising: > Stiffness > Antivibration > Stress absorption > Complete mechanical stability PROVEN STABILITY LOW FOUNDATION Thanks to its flat longitudinal axis design and low profile column connection, the machine's centre of gravity is kept very low: > Ensures high machine stability > Saves on foundation construction costs > Improves machine operation > Enhanced maintenance ergonomics LONG LASTING PRECISION Full cast iron, enabling: >...

Open the catalog to page 4

COMBINED GUIDING AND DAMPING SYSTEM SORALUCE is a pioneer in the use of linear guiding systems in high machining capacity equipment and heavy duty applications. HIGH ACCURACY Optimised machine structure and guiding system that guarantee the precision along the machine’s life. › The system combines our own specially developed hydrostatic damping elements with INA guiding systems on each axis › The system guarantees immense stability eliminating any vibration during machining processes › Using heavy duty linear guiding systems since 1992 INCREASED PRODUCTIVITY High dynamics on the axes and...

Open the catalog to page 5

DAS SYSTEM (DYNAMICS ACTIVE STABILISER) Beyond machine tool limits The DAS system is a device capable of actively increasing the dynamic rigidity of the machine, which reduces the risk of chatter and increases the cutting capacity by up to 300% improving dramatically the production time during the roughing process. The DAS system measures the vibrations during the machining process and generates, in real and time, by means of ram built-in actuators, an oscillation force that opposes the vibration. > Allows the use of maximum power throughout the whole working area > Up to 300% improvement...

Open the catalog to page 6

DYNAMIC HEAD CALIBRATION Even more accuracy in the working area Thanks to specific SORALUCE developments, head articulation positioning deviations have been reduced to a minimum. This system allows the compensation of head's kinematic values on the whole working area. > Automatic calibration for any type of head > Transparent for the user: Automatic calibration of the head without the need to use specific programming functions > Calibration of the head for any working area > Offset error compensation due to thermal expansion > Easy-to-use interface, 100% integrated with HEIDENHAIN and SIEMENS

Open the catalog to page 7

QUILL The benefits of traditional boring machines and the advantages of modern milling machines The system fully automatically interchanges the quill spindle with the other heads, thus enabling different quill spindles with different diameters and lengths likewise all necessary milling heads to machine components. Compared to traditional quill solutions, the exclusive SORALUCE modular quill spindle enables the same distance between quill spindle and milling heads to be upheld, enabling 5-sided machining in the same set-up without any additional re-positioning of the workpiece at a long...

Open the catalog to page 8

RAM BALANCE Improved precision in big working volumes for any head The Dynamic CNC Ram Balance System, patented by SORALUCE, takes care of ram geometrical accuracy, straightness and parallelism, when crossing vertical and cross axes and is specially indicated for machines equipped with head changing system. The system consists of a CNC controlled electromechanical system assembled within the vertical saddle and measured by a linear scale. It increases the precision, specially when the machine is equipped with the automatic head changing system, as it allows for accurate correction of the...

Open the catalog to page 9

INDUSTRY 4.0 In the framework of Industry 4.0, SORALUCE offers a comprehensive monitoring package based on cloud computing. Thanks to the revolutionary SORALUCE SMARTBOX M2C system (Machine-To-Cloud), the machine is connected online to the Cloud, where any significant events are recorded and can be used to deploy the associated services offered by SORALUCE under Industry 4.0. SORALUCE uses this Cloud-connected hardware structure to offer its SORALUCE Monitoring and Reporting service. > Machine control in real time at any time and from anywhere > Complete reporting service > Power...

Open the catalog to page 10

ACCURACY Machines incorporate intelligent systems which improve accuracy and increases productivity. MONITORING This enables users to connect to their machines from anywhere in the world via the SORALUCE website and to use their smart phone, tablet or PC to check sensitive indicators in real time, such as machine status (cycle, stop, alarm, etc.), ongoing program, tool on headstock, shaft and head speeds, power, status of overrides, etc. Output monitoring Details of machine output are provided using indicators such as machine availability, performance, interim and total production times per...

Open the catalog to page 11

THE COMPLETE WORKING AREA ANALYSED FOR AN OPTIMAL RESULT The new SORALUCE FR - FX - FXR Generation is based on a complete revision of the machine from the user's point of view focusing on improving operation efficiency and developing a Total Machine Concept. The Total Machine Concept takes into account the machine but also the complete working area. All the interactions of the operator with the different machine elements are analysed for an optimal implementation. Not only the machine, but the work area and its surroundings are analysed as a whole in order to guarantee an optimal final...

Open the catalog to page 12All DANOBATGROUP catalogs and technical brochures

-

PRG

24 Pages

-

IRIS

4 Pages

-

DANOBAT LB LASER BLANKING

4 Pages

-

DANOBAT BM BENDING

4 Pages

-

DANOBAT Railway Solutions

16 Pages

-

DANOBATGROUP Company profile

24 Pages

-

T3CH DRILLING SOLUTIONS

3 Pages

-

CPI MITRE BANSAWING MACHINES

3 Pages

-

TA-A BED TYPE MILLING CENTRE

12 Pages

Archived catalogs

-

Automatic Panel Bender PG

6 Pages