Website:

DANOBATGROUP

Website:

DANOBATGROUP

Group: DANOBATGROUP

Catalog excerpts

UTTING EDGE DANOBATGROUR boosting productivity through DANOBAT, projects that revolutionize sectors highest precision, productivity and reliability levels in milling,

Open the catalog to page 1

Dear reader, We are delighted to present to you the irst issue of Cutting Edge Magazine, a DANOBATGROUP initiative for sharing with you our latest projects and innovations developed in close collaboration with our customers. On this occasion, you will have the unique opportunity to read real customer testimonies about different cases of cutting edge projects developed hand in hand with them. DANOBATGROUP has a long track record of offering turnkey solutions to worldwide featured customers. Each project is taken as a new challenge where new developments will be implemented to bring real...

Open the catalog to page 3

© DANOBATGROUP 2013. This document is not a contract. DANOBATGROUP reserves the right of making changes to all models without prior notice. The illustrations in this magazine remain property of DANOBATGROUP .

Open the catalog to page 4

content DANOBATGROUP 04 | From Germany to Germany; the local added value through DANOBAT-OVERBECK and BIMATEC SORALUCE 07 | Boosting productivity through sustainability 10 | DANOBAT & LUCCHINI, the perfect partnership for the most advanced railway axle line 12 | Ultraprecision EMO 2013 Highlights 14 | DANOBAT grinding and turning machines 16 | SORALUCE millingboring and vertical turning machines 18 | DANOBAT sawing, drilling and 3D plasma cutting machines 30 | DANOBAT NA horizontal lathes to get the required precision levels 19 | LATZ cutting tools 32 | SORALUCE FXR-16000 Precision,...

Open the catalog to page 5

From Germany to Germany; the local added value through DANOBAT-OVERBECK and BIMATEC SORALUCE Germany is Europe’s leading manufacturer, consumer and exporter of machine tools, and has been the top destination for DANOBATGROUP’s sales for many years. For a company to be successful in the German market, its brand name must be well-known and acclaimed in this country. German customers are some of the most demanding in the world, not just for technology but also as regards quality, reliability and precision. They insist on only highly reliable, top-end products, and their service requirements...

Open the catalog to page 6

Mr. Josu Tornay - Managing Director of OVERBECK GmbH Q: 90 years of history have gone a long way. How do you assess the evolution of the company? Josu Tornay: Nowadays, due to the OVERBECK’s extensive applications experience we specialize in providing a complete tailor made solution within the shortest possible lead time and at a competitive price that will satisfy every customer’s demand for accuracy, repeatability, ease of use and increased productivity. This is veriied in stringent machine trials that take place in our factory prior to delivery and commissioning, with full traceability...

Open the catalog to page 7

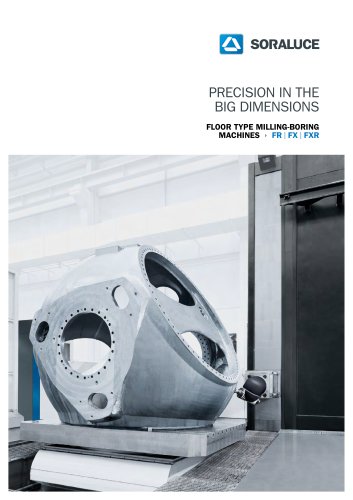

Mr. Fred Bisgwa, Co-founder member and Managing Director of BIMATEC SORALUCE BIMATEC SORALUCE Q: In view of the recent successes in sales, it is clear German customers appreciate SORALUCE technology. In your opinion what makes a customer choose SORALUCE milling boring machines from among others? Fred Bisgwa: Our German customers not only appreciate the high quality and performance of our machines, but also the comprehensive support in particular. This is the reason why almost 90% of our customers have more than one SORALUCE machine in use. Q: Customization requires great knowledge of...

Open the catalog to page 8

Boosting productivity through sustainability DANOBATGROUP offers sustainable production systems in harmony with the economy, ecology and society The tendency to energy eficiency represents the beginning of a paradigm shift for the machine tool sector. For a long time, the machine tool industry has been driven by the motivation to provide the most productive, the most precise and the most reliable machines to customers. Competitiveness has been deined and determined by manufacturing excellence. In the last few years, however, the machine tool sector has begun to invest in sustainable...

Open the catalog to page 9

MACHINE TOOL POWER OUTPUT Chip conveyor Feed drives Cabinet cooling Coolant fluid -Electrical drives with energy recovery -Mass reduced mechanicals ■High machine dynamics far cycle time reduction ■ Low friction guidance of mechanical ■Central cooling systems ■Emulation techniques ■Mufti technologies macnin&s ■ Inlelligent slanrJ-by models 01- Reduction measures to boost energy efficiency 02- Human-centered based assistance 03- New nozzle design DANOBATGROUP is currently working on different sustainability research areas to increase the energy efficiency on machines, to find new solutions to...

Open the catalog to page 10

03 | Human-centered based assistance Advantages at a glance: • Context-adaptive assistance for fault diagnosis • Mobile, personalized tutoring systems • Location-based maintenance and planning assistance • Assistance in complex work processes Efficient cooling in grinding; an optimized process cycle to face the scarcity of resources and avoid emissions Advantages at a glance: • Improvement of lubrication and cooling efficiency • Grinding wheel wear decrease / productivity increase • Reduction of pumping pressure and flow rate / energy saving

Open the catalog to page 11

DANOBAT & LUCCHINI, the perfect partnership for the most advanced railway axle line DANOBAT has created for LUCCHINI RS a new automatic line for machining and testing railway axles, mainly for high-speed trains. This investment forms part of a long-term plan for renovation of the Lovere plant, geared to innovation of products and processes that are essential for maintaining international leadership. The project was completed in record time, with the line beginning fullcapacity production just 18 months from DANOBAT’s receipt of the order to manufacture it. This production line was supplied...

Open the catalog to page 12

Photo by courtesy of Lucchini RS production times are shorter, there is less waste produced and it has lower dimensional tolerances that improve considerably the inal product and reduce manufacturing costs. Moreover, WIP inventory was signiicantly reduced and the throughput time was drastically shortened. complicated line brought up during the start-up period. Q: Joint work teams made up of engineers from both LUCCHINI RS and DANOBAT have taken part in the project. How do you rate this teamwork? Zaverio Tignonsini: The project has made a positive contribution to our modernisation plan, that...

Open the catalog to page 13All DANOBATGROUP catalogs and technical brochures

-

PRG

24 Pages

-

IRIS

4 Pages

-

DANOBAT LB LASER BLANKING

4 Pages

-

DANOBAT BM BENDING

4 Pages

-

DANOBAT Railway Solutions

16 Pages

-

DANOBATGROUP Company profile

24 Pages

-

T3CH DRILLING SOLUTIONS

3 Pages

-

CPI MITRE BANSAWING MACHINES

3 Pages

-

TA-A BED TYPE MILLING CENTRE

12 Pages

Archived catalogs

-

Automatic Panel Bender PG

6 Pages