Catalog excerpts

CURVE CONVEYING The different diameters over the length the tapered roller i.e. small one end and large the other end, provides conveying of goods around the curve. The roller axis is installed at a defined angle θ/2 (θ =3.6°).

Open the catalog to page 1

Rollers are listed according to their series and available features. Product features Small head diameter Driving element Tapered sleeve, attractive, low noise. Tapered sleeve, O-Belt drive, light duty conveying, groove position customized. Tapered sleeve, O-belt drive, light duty conveying, smooth running. Tapered sleeve, poly-vee drive, Medium duty conveying, high speed, low noise. Tapered sleeve, polymer sprocket, medium duty conveying, attractive, low noise. Steel tube, medium duty conveying, strong, durable. Steel tube and sprocket, medium duty conveying, strong, durable.

Open the catalog to page 2

Turn Radius In theory, the geometric extension line of the tapered roller should join with the centre of the circle of the curve frame. By using this method, you can achieve the ideal curve for conveying. It may be calculated using the formula below: In the formula : R--turn (inner) radius D--diameter of the smaller head of the taper roller K--conical degree (the conical degree is expressed by fraction, eg. 1/16, 1/30, it's reduction formula is K=2*tan 0/2 c--the space between the tapered roller's smaller head and the inner side of the frame. Roller Pitch The design of roller pitch should...

Open the catalog to page 3

1600 Series Gravity Tapered Sleeve Roller Product Features • Based on the 1200 Series, fitted with a grey polypropylene taper sleeve; abrasion resistant, low noise, shockproof. • The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller. • The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water. • The roller is light, easy to start-up. • Temperature range: -5°C ~ 40°C.

Open the catalog to page 4

1600 Series Tapered Sleeve Roller Tube Dia.

Open the catalog to page 5

2640 Series Double Grooved Tapered Sleeve Roller Product Features • Based on the 2240 Series, covered with grey polypropylene taper sleeve; abrasion resistant, low noise, shockproof. • The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller. • The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water. • The roller is light, easy to start-up. • The position of the grooves can be customized. • The load capacity of the roller depends on...

Open the catalog to page 7

2640 Series Spring Loaded Tube Dia.

Open the catalog to page 8

2640 Series Tapered Sleeve Roller 2640 Series Internal Thread Tube Dia.

Open the catalog to page 9

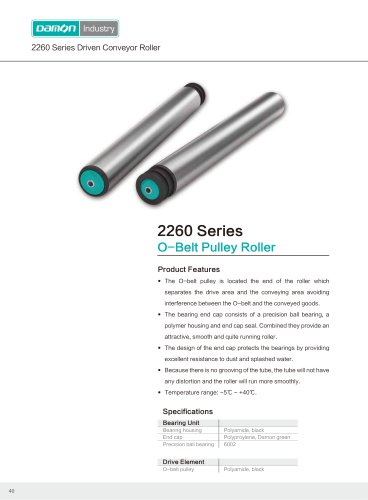

2660 Series Double Groove O-Belt Pulley Tapered Sleeve Roller Product Features • Based on the 2260 Series, covered with grey polypropylene taper sleeve; abrasion resistant, low noise, shockproof. • The O-belt pulley is located on the head end of the roller which separates the drive area and the conveying area avoiding interference between the O-belt and the conveyed goods. • The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller. • The design of the end cap protects the bearings by...

Open the catalog to page 10

2660 Series Tapered Sleeve Roller 2660 Series Spring Loaded Tube Dia.

Open the catalog to page 11

2660 Series Internal Thread Tube Dia.

Open the catalog to page 12

2650 Series Tapered Sleeve Roller 2650 Series Poly-Vee Tapered Sleeve Roller Product Features • Based on the 2250 Series, covered with grey polypropylene taper sleeve; abrasion resistant, low noise, shockproof. • The poly-vee pulley is located on the head end of the roller which separates the drive area and the conveying area avoiding interference between the poly-vee belt and the conveyed goods. • The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller. • The design of the end cap...

Open the catalog to page 13

2650 Series Spring Loaded Tube Dia.

Open the catalog to page 14

2650 Series Tapered Sleeve Roller 2650 Series Internal Thread Tube Dia.

Open the catalog to page 15

2624 Series Polymer Sprocket Tapered Sleeve Roller Product Features • Based on the 2224 Series, covered with grey polypropylene taper sleeve; abrasion resistant, low noise, shockproof. • Using the polyamide sprocket roller as the drive element reduces the running noise. • The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller. • The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water. • To avoid abrasion between the sprocket and...

Open the catalog to page 16

2624 Series Tapered Sleeve Roller 2624 Series Internal Thread Tube Dia.

Open the catalog to page 17

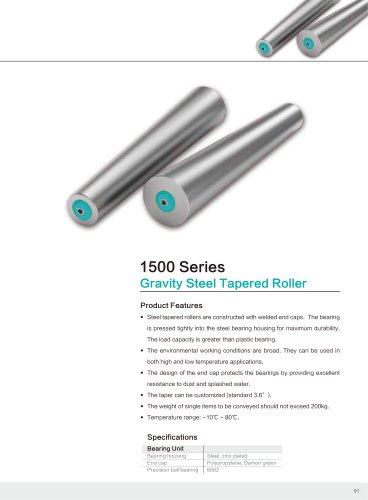

1500 SeriesGravity Steel Tapered Roller Product Features • Steel tapered rollers are constructed with welded end caps. The bearing is pressed tightly into the steel bearing housing for maximum durability. The load capacity is greater than plastic bearing. • The environmental working conditions are broad. They can be used in both high and low temperature applications. • The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water. • The taper can be customized (standard 3.6° ). • The weight of single items to be conveyed should not exceed...

Open the catalog to page 18

1500 Series Tapered Sleeve Roller Internal Thread Tube Steel, zinc plated

Open the catalog to page 19

2521 SeriesSprocket Steel Tapered Roller Product Features • Welding the steel sprocket to the tapered steel tube gives it the capacity to transmit high torque making it suitable for medium/heavy duty loads. • The environmental working conditions are broad. They can be used in both high and low temperature applications. • The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water. • The taper can be customized (standard 3.6° ). • Narrow tooth sprockets are used to provide smooth roller rotation. • The weight of single items to be conveyed...

Open the catalog to page 20All DAMON Industrial Europe Srl catalogs and technical brochures

-

Belt Conveyor Pulley

8 Pages

-

Gravity Conveyor Roller Series

18 Pages

-

Driven Conveyor Roller Series

32 Pages

![COMPREHENSIVE PRODUCTS OVERVIEW[201905V1(2)]](https://img.directindustry.com/pdf/repository_di/189845/comprehensive-products-overview-201905v1-2-838629_1mg.jpg)