Catalog excerpts

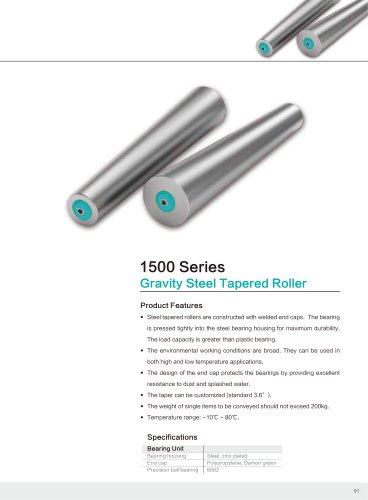

1600 Series Curve Conveyor Roller In theory, the geometric extension line of the tapered roller should join with the centre of the radius of the curve frame. By using this method, you can achieve the ideal curve for conveying. It may be calculated using the formula below: Turn Radius R —— turn (inner) radius D —— diameter of the smaller head of the taper roller K —— conical degree ( the conical degree is expressed by fraction, eg. 1/16, 1/30, it's reduction formula is K=2*tanθ/2 c —— the space between the tapered roller's smaller head and the inner side of the frame. Taper Small dia.(D) Curve radius(R) Roller Pitch Calculating Roller Length The design of roller pitch should follow the principle of For straight conveying, generally there is no need to “minimum 3 rollers to support the goods at any moment” (refer to P*) consider the length of the goods but for curved conveying, the length and width of goods and the curve radius are all influencing factors. It may be For 2650 series poly-vee tapered rollers the The angle between tapered rollers should not exceed calculated using the formula below: recommended pitch of poly-vee pulleys is 73.7mm. BF—— frame inner width R —— turn (inner) radius B —— width of goods L —— length of goods After confirming BF, you can calculate the roller length W and taper sleeve length WT by the available series of tapered roller. The tapered sleeve is the working surface of the tapered roller. The tapered sleeve length WT is available in increments of 50mm. Adjust the calculation result based on the formula. E.g.:W计=628,WT=600 W计=561,WT=550 ! Based on the width of goods, the calculated roller length for a curve is longer than that for a straight conveyor. Typically, the length of the roller for the curve would be used as the default roller length for the entire conveyor system. Where it is not convenient to utilize a uniform roller length, a transitional straight conveyor will need to be installed. Gravity Tapered Sleeve Roller Based on the 1200 Series, fitted with a grey polypropylene taper sleeve; abrasion resistant, low noise, shockproof. ● The bearing end cap consists of a precision ball bearing, a polymer housing and end cap seal. Combined they provide an attractive, smooth and quite running roller. The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water. The roller is light, easy to start-up. Specifications Bearing Unit Bearing housing End cap Precision bal

Open the catalog to page 1

1600 Series Curve Conveyor Roller In theory, the geometric extension line of the tapered roller should join with the centre of the radius of the curve frame. By using this method, you can achieve the ideal curve for conveying. It may be calculated using the formula below: Turn Radius R —— turn (inner) radius D —— diameter of the smaller head of the taper roller K —— conical degree ( the conical degree is expressed by fraction, eg. 1/16, 1/30, it's reduction formula is K=2*tanθ/2 c —— the space between the tapered roller's smaller head and the inner side of the frame. Taper Small dia.(D)...

Open the catalog to page 2

1600 Series Curve Conveyor Roller 1600 Series Tube Dia.(D) Steel, zinc plated, tapered sleeve Shaft Dia.(d) Spring Loaded Steel, zinc plated, tapered sleeve Shaft Dia.(d) Internal Thread

Open the catalog to page 3

Tube Dia.(D)

Open the catalog to page 4All DAMON Industrial Europe Srl catalogs and technical brochures

-

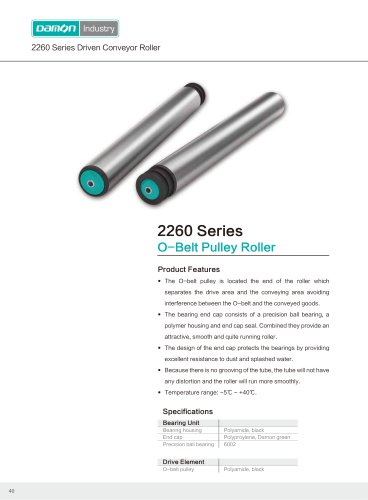

Belt Conveyor Pulley

8 Pages

-

Gravity Conveyor Roller Series

18 Pages

-

Driven Conveyor Roller Series

32 Pages

-

Taper Conveyor Roller Series

22 Pages

![COMPREHENSIVE PRODUCTS OVERVIEW[201905V1(2)]](https://img.directindustry.com/pdf/repository_di/189845/comprehensive-products-overview-201905v1-2-838629_1mg.jpg)