Catalog excerpts

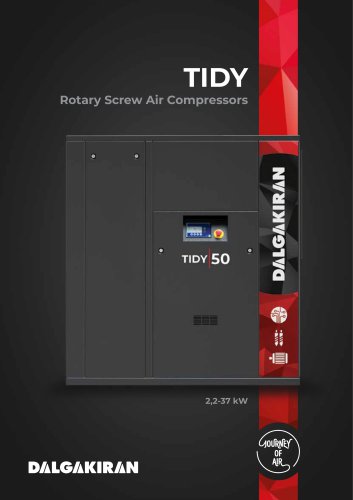

TIDY Series Rotary Screw Air Compressors TIDY 20BI TIDY 25 / TIDY 30 / TIDY 401 TIDY 40 B / TIDY 50 ROTARY SCREW BLOCK • New generation rotary screw blocks, designed with latest technological tools like "Computational Fluid Dynamics (CFD)" and "Finite Element Method (FEM)" and manufactured using high-end manufacturing techniques, provide high efficiency, durability and low energy consumption with new rotor profile and lobe • Block contains new generation bearing system in which the bearings with three times more load carrying capacity than the standard designs are employed. • As new rotor profile permits less air leakage occurrences with optimal lobe combination and decreases the torque needed to operate, less energy is needed to operate that leads to less operating costs. MAIN MOTOR AND DRIVE SYSTEM • High efficiency IE2 class IP55 motors working with 380V/3 phase/50Hz power inlet are used as a standard • Driving the rotor shaft is realized by a belt-pulley mechanism placed between rotary screw block and main motor and selected considering a suitable transmission ratio. • Belts are chosen by considering the working life of • The pulley with bushing eases assembly-disassembly • With easy adjustment of belt tension, continuously efficient operation of the compressor is secured. • More effective separation is realized at less volume with the progressive type, deep bedded and meshed separation layers. • These separators have high performance design providing three-stage separation. • Less than 3 mg/m3 of oil density is transferred with compressed air during separation. • Spin-on type separators are used in TIDY series so that they can be replaced easily without the need of evacuating the oil from the tank and thus the maintenance duration lessens as well as the maintenance costs noticeably decreases. • Developed by using sophisticated engineering analysis tools like FEM and "Fluid • The main feature of the suction regulator is its user-friendly design to meet the user's performance and maintenance demands. • First class materials used in the suction regulator manufacturing and lessened seal amounts provide reliable operating performance up to 8000 hours. • As neither piston nor spring is used in the design of the regulator valve, the noticeable decrease in the dimensions, opening and closing of the valve with just air and realizing the suction with this way are provided. (TIDY 3-20) • Air suction fan helps with increasing capacity as well as providing effective cooling with the creation of turbo effect. (TIDY 3-20) • With its simple design consisting of three control block units, a solenoid valve and a control cylinder, periodical maintenance services of the suction regulators are easily and quickly realized. (TIDY20B-50) • With the suction valve which gets fully perpendicular position when it's opened, almost straight and unidirectional airflow, increased air outlet area by %25 with the new profile design, the suction regulator promises low pressure drops and high • Double stage air suction filter system consisting of replaceable front-panel filter from micro-glass fiber, replaceable cassette type air intake filter with paper element minimizes the problems caused in dirty environments by providing clean air for the rotary screw block and the cooling system.

Open the catalog to page 1

TIDY Series Rotary Screw Air Compressors COOLING SYSTEM • Aluminum combi cooler with long-life Bar/Rate system guarantees trouble-free operation at all kinds of • Four-way thermostatic valve lengthens the lifecycle of oil and eliminates the risks of malfunctioning by preventing condensation at low temperatures. • Temperature controlled cooling fans supports the thermostatic valve as well as provides extra energy- saving opportunities at cold ambient conditions. (TIDY20B-50) • New blade profiles are supported with silent and effective axial fans directly coupled to the main motor shaft (TIDY...

Open the catalog to page 2All DALGAKIRAN KOMPRESOR catalogs and technical brochures

-

RSC SERIES

4 Pages

-

DVK SERIES

4 Pages

-

DPR D SERIES

4 Pages

-

INVERSYS DPR SERIES

4 Pages

-

EAGLE SERIES

8 Pages

-

INVERSYS PLUS SERIES

4 Pages

-

PORTAIR Series

2 Pages

-

DVK

2 Pages

-

INVERSYS PLUS

2 Pages

-

WAVE

2 Pages

-

DBK

2 Pages

-

Marine compressors

2 Pages

-

Boosters Compressors

4 Pages

-

Double Stage Compressors

4 Pages

-

Single Stage Compressors

4 Pages

-

DOC Oil Free Systems

2 Pages

-

DVK 60-430 screw compressors

4 Pages

Archived catalogs

-

TIDY SERIES

4 Pages