Catalog excerpts

Single and Double Stage Reciprocating Air Compressors COMPRESSOR BLOCK • Heavy duty cast-iron crankcases contain properly placed oil level indicators, oil filling/draining plugs and crankcase ventilation system. • Cast-iron cylinders and bare pumps with cooling fins help the system preventing overheat • Dynamically balanced and precisely manufactured sphero cast crankshafts provide long lifecycle. • Lightweight pistons and connecting rods casted from special aluminum alloy not only apply less pressure to crankshaft but also prevent it from overheating with high heat transfer capability • Special design finger-type high capacity and high pressure-resistant inlet-outlet valves made from stainless steel are capable of holding airflow in upper levels as well as operating at high temperatures. • Compression and oil retaining rings are used for holding the airflow maximized and preventing oil leakages. MAIN MOTOR AND DRIVE SYSTEM • High efficiency IE2 class IP55 motors working with 380V/3 phase/50Hz power inlet are used as a standard in reciprocating air compressors. • Driving the crankshaft is realized by a belt-pulley mechanism placed between compressor block and main motor and selected considering a suitable transmission ratio. • Belts are chosen by considering the working life of minimum 25,000 hours. • Special design fan type cast-iron pulleys not only provide airflow with large volumes to cool compressor block but also act as a flywheel to damp the vibrations occurred during operation. • With easy adjustment of belt tension, continuously efficient operation SAFETY SYSTEMS • The solenoid valve for loadless start (for 4kW motor power and more) • Pressure switch • Non-return valve • Belt-pulley guard • Safety valve

Open the catalog to page 1

Single and Double Stage Reciprocating Air Compressors STANDARD FEATURES • Reciprocating compressor block • CE certified air receiver made from P265GH pressure vessel steel • 380V/3 phase/50Hz IE2 efficiency class IP55 main motor • Drive system with belt-pulley mechanism • Special design fan type cast-iron pulley • Long-lasting bearings • Air intake filter and silencer for loadless operation • Lubrication system with whisking rod • Automatic condensate drain valve for air receiver • Thermic magnetic circuit-breaker • Motor drive system with star-delta connection (between 5.5-7.5kW motor...

Open the catalog to page 2All DALGAKIRAN KOMPRESOR catalogs and technical brochures

-

RSC SERIES

4 Pages

-

DVK SERIES

4 Pages

-

DPR D SERIES

4 Pages

-

INVERSYS DPR SERIES

4 Pages

-

EAGLE SERIES

8 Pages

-

INVERSYS PLUS SERIES

4 Pages

-

PORTAIR Series

2 Pages

-

DVK

2 Pages

-

INVERSYS PLUS

2 Pages

-

WAVE

2 Pages

-

DBK

2 Pages

-

Marine compressors

2 Pages

-

Boosters Compressors

4 Pages

-

Double Stage Compressors

4 Pages

-

Single Stage Compressors

4 Pages

-

DOC Oil Free Systems

2 Pages

-

DVK 60-430 screw compressors

4 Pages

Archived catalogs

-

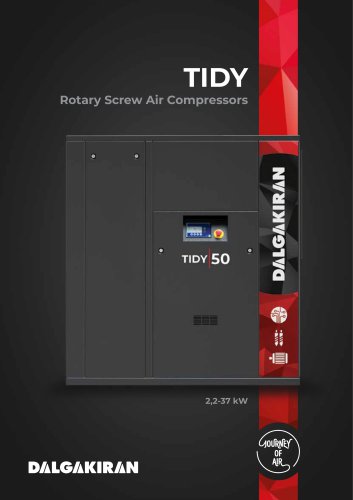

TIDY SERIES

4 Pages