Catalog excerpts

Pathfinder® Air-Cooled Chillers Model AWS-C ■ Standard, High & Premium Efficiencies

Open the catalog to page 1

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . 4 Installation and Application Considerations . . . . . . 7 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Physical Data (non-VFD) . . . . . . . . . . . . . . . . . . . . . . 18 Physical Data (VFD) . . . . . . . . . . . . . . . . . . . . . . . . . . 36 Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . 41 Sound Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 Field Wiring...

Open the catalog to page 2

Air-Cooled Chiller Products Air-Cooled Scroll Compressor Chiller Model AGZ-B • 10 - 34 RT Air-Cooled Scroll Compressor Chiller Model AGZ-E • 30 - 70 RT Model AGZ-D • 75 - 190 RT Remote Evaporator and Pump Package options available Air-Cooled Screw Compressor Chiller Model AGS • 140 - 200 RT Pathfinder® Air-Cooled Screw Compressor Chiller Model AWS • 170 - 550 RT Standard, High, and Premium Efficency VFD and Remote Evaporator options available The Daikin Pathfinder® air-cooled chillers continue our legacy of high quality, high efficiency, advanced technology and quiet operation. Pathfinder®...

Open the catalog to page 3

Features and Benefits PATHFINDER® CHILLER NOMENCLATURE AWS XXX C D S E Unit configuration E = Standard packaged M = Remote Evaporator Model AWS = Air-Cooled World Product Screw Compressor Nominal unit size (cataloged size—nominal unit capacity) Unit efficiency S = Standard H = High P = Premium Design vintage Unit compressors D = Dual compressors T = Triple compressors Features and Benefits Three major benefits separate the air-cooled screw chillers: chiller from most • Low operating costs with our high and premium efficiency designs • Very quiet operation allowing for flexible location •...

Open the catalog to page 4

Proven Reliability Full factory testing of every packaged unit ensures troublefree start-up, reliable operation, and minimizes expensive field repairs. A zero clearance fit between the two gaterotors and main screw rotor virtually eliminates leakage between the high and low-pressure sides during compression. Special gaterotor material made from an advanced composite, temperature stable material makes a zero clearance design possible with no detrimental metal-to-metal contact. Excellent Serviceability Field serviceability has not been sacrificed to meet design performance objectives....

Open the catalog to page 5

Wye-Delta Reduced-Voltage Starter Daikin Applied offers the wye-delta reduced voltage starters and an option of solid state starters. In the “Y” configuration, each set of phase windings is brought together at a common point reducing the current and torque to 33% of full in-rush. Three contactors and a timer are used to switch the six leads brought out of the motor from the Y-connection to the Delta configuration in a two-step starting process. Variable Frequency Drive (VFD) The variable frequency drive option is a technology that has been used for decades to control motor speed on a wide...

Open the catalog to page 6

Installation and Application Considerations Installation and Application Considerations Table 1: Operating Limits Maximum standby ambient temperature Maximum operating ambient temperature with optional high ambient package (detailed information on page 97) Note: some standard efficiency units may not operate fully loaded up to the 125°F maximum ambient temperature limit. Contact the Daikin Applied sales office for information. Minimum operating ambient temperature (standard control) Minimum operating ambient temperature (with optional low-ambient control) Leaving chilled water temperature...

Open the catalog to page 7

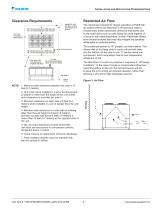

INSTALLATION AND APPLICATION CONSIDERATIONS Clearance Requirements 5ft [1.5m)if openfence or 50% open wall operation, airflow 5ft [1.5m)if open fence or 50% open wall 6ft ("I.Smjif solidwall (see note 3 for pit) above unit atany height The clearances required for design operation of Pathfinder air-cooled chillers are described in the previous section. Occasionally, these clearances cannot be maintained due to site restrictions such as units being too close together or a fence or wall restricting airflow, or both. Pathfinder chillers have several features that may help mitigate the penalties...

Open the catalog to page 8

INSTALLATION AND APPLICATION CONSIDERATIONS Case 1: Building or Wall on One Side of Unit The existence of a screening wall or the wall of a building in close proximity to an air-cooled chiller is common in both rooftop and ground level applications. Hot air recirculation on the coils adjoining the wall will increase compressor discharge pressure, decreasing capacity and increasing power When close to a wall, it is desirable to place chillers on the north or east side of them. It is also desirable to have prevailing winds blowing parallel to the unit's long axis. The worst case is to have...

Open the catalog to page 9

INSTALLATION AND APPLICATION CONSIDERATIONS Case 3: Three or More Units Side By Side When three or more units are side by side, the outside chillers (1 and 3 in this case) are influenced by the middle unit only on their inside circuits. Their adjustment factors will be the same as Case 2. All inside units (only number 2 in this case) are influenced on both sides and must be adjusted by the factors shown below. Figure 6: Three or More Units - Adjustment Factor Chiller 1 Chiller 2 Chiller 3 Distance Between Units in ft. (ml Full Load Power Adjustment Factor Distance Between Units in ft. (in}...

Open the catalog to page 10

Installation and Application Considerations Case 5: Pit/Solid Wall Installation Pit installations can cause operating problems resulting from recirculation and restriction can both occur. A solid wall surrounding a unit is substantially the same as a pit and the data presented here should be used. Steel grating is sometimes used to cover a pit to prevent accidental falls or trips into the pit. The grating material and installation design must be strong enough to prevent such accidents, yet provide abundant open area to avoid serious recirculation problems. Have any pit installation reviewed...

Open the catalog to page 11All Daikin Applied catalogs and technical brochures

-

Maverick® II systems

2 Pages

-

Destiny® Indoor Air Handler

28 Pages

-

Rebel® Refrigeration Only

1 Pages

-

PreciseLine®

4 Pages

-

OptiLine™

2 Pages

-

CAT 413-4 Steam Coils

23 Pages

-

CAT 412-6 Water Heating Coils

32 Pages

-

CAT 903 Air Terminal Units

106 Pages

-

Daikin Applied 2014

247 Pages

-

CAT 610-1 (AGSD 140-200 tons)

88 Pages