Website:

A&D COMPANY, LIMITED

Website:

A&D COMPANY, LIMITED

Group: A&D

Catalog excerpts

SVV-- S > S S iinnee--wwaavveeVViibbrrooVViissccoommeetteerr A A See S riiee r s s > UUsseerrssҒHHaannddbbooookk Version 1.13E June 2009International Div., A&D Company, Limited VViissccoommeettrryyRReevvoolluuttiioonn!! size="-1">

Open the catalog to page 1

SV-A Series Users Handbook Ver.1.13E A esurement isosity 1. Introduction Measuring viscosity is an effective method of determining the state (properties of matter) or the fluidity of a liquid or a gas. For example, the viscosity of a liquid is an important parameter for designing the piping in a plant, or transporting crude oil or chemical agent through a pipeline. Viscosity measurement has played an important role in, to say nothing of the petrochemical industry, a wide range of industries such as the food, printing (ink), medical drug, or cosmetics industries, as well as in quality...

Open the catalog to page 4

SV-A Series Users Handbook Ver.1.13E Basis/ A. Measurement/ 1. Viscosity > ҆ Tangential Stress Where a plane passes through a given point P in a fluid, each part of the fluidon both sides of the plane exert forces on each other. The force (stress) pe r unit area of the plane is resolved into a tangential component and a normalcomponent; they are called a tangential stress and a normal stressrespectively. For example, when it is a resting fluid, the tangential stress is zeroand the normal stress exerts pressure. > Tangential Stress Normal StressPlane

Open the catalog to page 5

SV-A Series Users Handbook Ver.1.13E Basis/ A. Measurement/ 1. Viscosity 2. Viscosity Viscosity, which is also called a viscosity coefficient, is the substance constant indicating the magnitude of the ғfluidity of a fluid. LetԒs look at viscosity from a physics point of view in order to understand and define it properly. As shown in Figure 2, the two plates, board A and board B, are placed parallel to each other and filled with a liquid (fluid). The distance between board A and board B is y > Board B Board ALiquid(Fluid) . Where board A is fixed and board B is being moved parallel to board...

Open the catalog to page 6

SV-A Series Users Handbook Ver.1.13E Basis/ A. Measurement/ 1. Viscosity Figure 3 shows the relationship between shear rate D and shear stress > Shear Stress Shear Rate D Figure 3 . As straight line shows, where they are in proportion indicating a constant slope of the line, it is a Newtonian fluid. Where > Ғ stands for the slope, viscosity is represented by the following equation (4); > > The fluids with fluidities such as indicated by lines - are non-Newtonian fluids. Viscosity /D varies in response to the quantity of shear rate, and the viscosity will not be constant. Curved line shows...

Open the catalog to page 7

SV-A Series Users Handbook Ver.1.13E Basis/ A. Measurement/ 1. Viscosity 3. Units of Viscosity According to the equation (3) aforementioned, viscosity is = /D. This is represented by SI units based on the MKS system of units as follows: (i) Shear stress is force per unit area. The unit of force is Newton (N). Therefore the unit of is N/m > 2 or Pascal [Pa], which is the unit of stress (pressure). (ii) Shear rate D is defined as dV/dy by the equation (1), and is represented by the unit [s > -1 ], which was given by dividing the unit [m/s] of speed V by the unit [m] of distance y. Therefore,...

Open the catalog to page 8

SV-A Series Users Handbook Ver.1.13E Measurement Method > Basis/ A. Measurement/ 2. Measurement Method Measuring viscosity coefficient is useful for evaluating viscidity. Several types of viscometer havebeen developed for research and development, or various industries. Viscometers are classified into the following types by the measurement principle. As of today, viscometers 1) to 4) below arestandardized as the JIS viscosity measurement method. 1) Vibro viscometer: Measures viscosity by controlling the amplitude of the sensor plates immersedin a sample and measuring the electric current to...

Open the catalog to page 9

SV-A Series Users Handbook Ver.1.13E Basis/ A. Measurement/ 2. Measurement Method 3. Capillary Viscometer When the laminar flow of liquid flows through a cylindrical capillary tube, as shown in Figure 7, where symbol Q stands for the volume of flow per unit time (flow rate), 2r for the diameter, L for the length of the capillary tube, P > Flow rate QPressure sensor Pressure sensor Proportioning PumpCapillary tube Capillary Tube of 2r diameter and L length 1 and P > 2 for the pressures at the both ends of the capillary tube, and the pressure differential P > 1 - P > 2 is > Figure 7 Principle...

Open the catalog to page 11

SV-A Series Users Handbook Ver.1.13E Basis/ A. Measurement/ 2. Measurement Method The principles and structure of the capillary viscometer are simple. However, you need to pay a lot of attention to the measuring operation, which requires many troublesome processes, in order to achieve accurate measurement. For instance, special care is needed when cleaning the inside of the capillary viscometer; before measurement you need to perform ultrasonic cleansing a few times using a cleaning liquid such as benzene and then dry, followed by another ultrasonic cleansing now with acetone and then dry,...

Open the catalog to page 12

SV-A Series Users Handbook Ver.1.13E > Kinetic viscosity [mm > 2 /s] Viscosity [mPas] Type Ref. Approximate value Approximate value >

Open the catalog to page 13

Temp. t (հC) Visco. (mPas) Kine. Visco. (mm > 2 Temp. t (հC) Kine. Visco.(mm Visco. > 2 /s) /s) (mPas) >

Open the catalog to page 14

SV-A Series Users Handbook Ver.1.13E C. Calibration > Basis/ C. Calibration No. > 1 Can a user perform viscosity coefficient calibration? Yes. Users can calibrate the SV-A Series using Viscosity Standard Fluids (aforementioned) or a liquid whose viscosity is under your control. When calibrating your viscometer, since theviscosity of Viscosity Standard Fluid depends on the temperature, before inputting a calibration value, you need to make a temperature correction of the viscosity coefficient of thestandard fluidin response to the temperature displayed while measuring a sample. As to...

Open the catalog to page 15

SV-A Series Users Handbook Ver.1.13E Basis/ C. Calibration No. > 3 How is viscosity calibration performed? For both one-point and two-point calibrations, enter the product of the absolute viscosity value and the density of the Viscosity Standard Fluidas the correction value. After calibration, check the values, comparing the product described in the preceding sentence with the displayed value. From the equation (8), Density = Viscosity / Kinetic viscosity Therefore, The displayed value of the SV-A Series, Viscosity җ Density = Viscosity > 2 / Kinetic viscosity Example 1: To calibrate the...

Open the catalog to page 16All A&D COMPANY catalogs and technical brochures

-

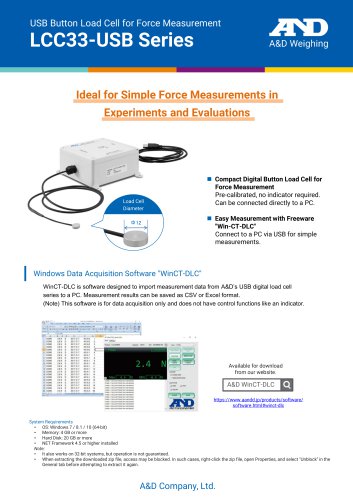

LCC33-USB

2 Pages

-

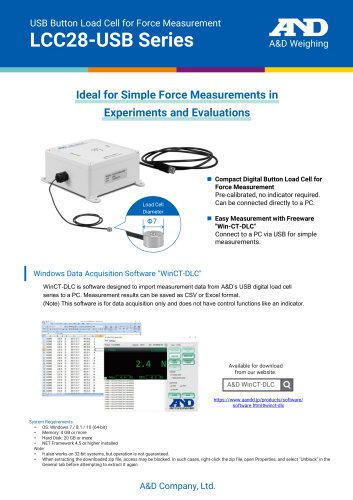

LCC28-USB

2 Pages

-

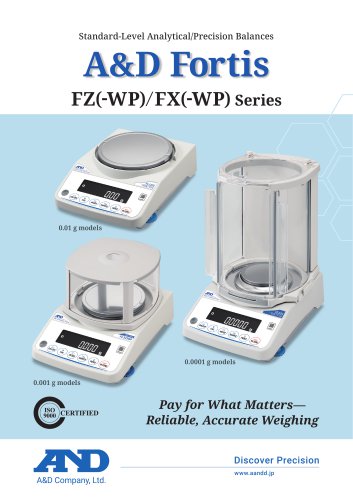

FZ(-WP)/FX(-WP) Series

8 Pages

-

LC1205-USB

2 Pages

-

CMX-USB

1 Pages

-

LCC20

1 Pages

-

LC4001/LC4001A

1 Pages

-

AD-4329A

4 Pages

-

AD4329A-DLC & LCCD20

4 Pages

-

AD-4401A

4 Pages

-

AD-4402

6 Pages

-

AD-4408C

2 Pages

-

AD-4410

6 Pages

-

AD-4403FP

4 Pages

-

AD-4430 series

6 Pages

-

AD4413-CW

2 Pages

-

AD4412-CW

6 Pages

-

AD-4411 Series

2 Pages

-

GC Series of Counting Scales

8 Pages

-

AD-4531B

2 Pages

-

AD-4530

2 Pages

-

LCM13 Series

2 Pages

-

Moisture Analyzer/M series

6 Pages

-

Data Acquisition System Omniace

16 Pages

-

Pipette Management Solutions

8 Pages

-

Laboratory Solutions by A&D

12 Pages

-

AD-1612 Comparator Buzzer

2 Pages

-

AD-1641 Air Flow Logger

4 Pages

-

Leak Tester/AD-1690

2 Pages

-

Weighing Data Logger/AD-1688

2 Pages

-

Washdown Scales/SC&SE Series

4 Pages

-

Users handbook for M series

30 Pages

-

Digital Indicator/AD-4532B

4 Pages

Archived catalogs

-

Press Release/FZ-i series

3 Pages