Website:

A&D COMPANY, LIMITED

Website:

A&D COMPANY, LIMITED

Group: A&D

Catalog excerpts

SICE Annual Conference 2005 in Okayama, August 8-10, 2005 Okayama University, Japan 1 JGC Corporation (Nikki K. K.), Information Technology Department 2-3-1, Minato Mirai, Nishi-ku, yokohama, 220-6001, Japan noguchi.yoshikazu@jgc.co.jp, kobari.masanori@jgc.co.jp Abstract: JGC proposes a practical solution to the temperature control issues for batch process reactors by combining model predictive controller and silicone oil based single heat transfer fluid. By combination of model predictive controller and Single Silicone oil based heating / cooling media, it is possible to realize the good temperature control performance for wide temperature range, i.e. minus 50degC to 150degC. By using the new controller design environment with A&Ds controller, it is possible to reduce the installation time of the designed controller on the MATLAB / Simulink to the target machine (A&DҒs controller) dramatically, less than 1/3. Keywords: Model predictive control, Batch Reactor, Single Heat Transfer Fluid > In the batch process, temperature control performance of the fluid inside the batch reactor using heating or cooling media is the most important factor to determine the product quality or to minimize the by-product generation. Recently, one common batch reactor is used to produce wider range of product recipes or wider range of operation ranges. In order to obtain good quality of the product or to minimize the by-product generation, the temperature control loop performance shall not be degraded during batch operation even if the product recipe or operation condition is changed. Generally speaking, the volume, physical properties, such as density and specific heat, of the fluid inside the batch reactor are changed during the batch process or time and process dynamics such as process gain or time constant are changed. Therefore, a PID controller with a set of tuning parameter doesnt show good control performance over the wide operating condition during batch operation. > Flexthermo uses a Single Transfer Fluid, Silicone Oil. By using a Single transfer fluid, we can keep the control mode of the temperature controller in AUTO for all temperature range as shown in Fig.1 and we can simplify the piping configuration dramatically as shown in Fig. 2. > Multiple Heating Media Multiple Heating Media ! ! ! Model Predictive Control (MPC) has been widely used especially in Oil Refining & Petrochemical industry over the past 20 years and its superior controllability compared with the performance of the conventional PID controller has already been recognized by the MPC users. However, there are a few reports for the MPC applications for batch process. This is because the conventional MPC with a set of tuning parameter doesnҒt also show good control performance over the wide operating condition during batch operation. In addition to these conventional controllers, to use a batch reactor to produce wide variety of products, we have to use several conventional heating or cooling media by switching the media during the batch for wide temperature range, such as minus 50degC to > ! ! ! ! ! ! Single Heating Media Single Heating Media 150degC. During the media switching, it is not possible to keep the temperature controller mode as AUTO, because we have to empty the jackets or coil of the reactor during media switching. JGC propose the practical solution to these temperature control issues for batch reactors called Flexthermoӓ , i.e., combination of model predictive controller for batch reactors and silicone oil based single heat transfer fluid. Fig. 1. Operation Range for Heating Media Fig. 2. Comparison of Multiple & Single Heat/ Cool Media > - 449 - PR0001/05/0000-0449 400 ũ 2005 SICE size="-2">

Open the catalog to page 1

CPUCPUCPUSequencecontrol CPUCPUCPUSequencecontrol SCADA SCADA PCRcontrolLoopcontrol PCRcontrolLoopcontrol BatchReactorMultipleCPU BatchReactorMultipleCPU Without disturbance compensation Withoutdisturbancecompensation Step Test Step Test Step Test > With disturbance compensation Withdisturbancecompensation Model Identification Model Identification Model Identification > Controller Design Controller Design Controller Design Closed Loop Simulation > Functions assign to each CPUs Functions assign to each CPUs Build up PCR ProgramBuild up Sequence Control ProgramClosed Loop Simulation Build up...

Open the catalog to page 3All A&D COMPANY catalogs and technical brochures

-

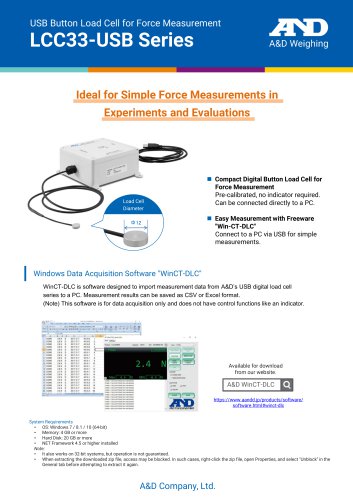

LCC33-USB

2 Pages

-

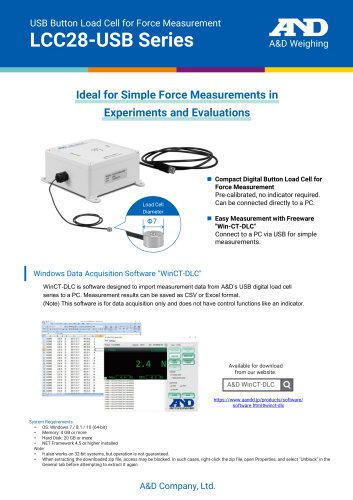

LCC28-USB

2 Pages

-

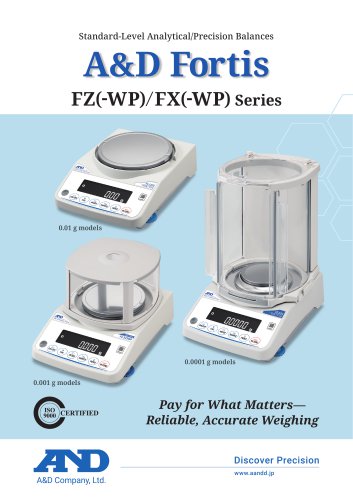

FZ(-WP)/FX(-WP) Series

8 Pages

-

LC1205-USB

2 Pages

-

CMX-USB

1 Pages

-

LCC20

1 Pages

-

LC4001/LC4001A

1 Pages

-

AD-4329A

4 Pages

-

AD4329A-DLC & LCCD20

4 Pages

-

AD-4401A

4 Pages

-

AD-4402

6 Pages

-

AD-4408C

2 Pages

-

AD-4410

6 Pages

-

AD-4403FP

4 Pages

-

AD-4430 series

6 Pages

-

AD4413-CW

2 Pages

-

AD4412-CW

6 Pages

-

AD-4411 Series

2 Pages

-

GC Series of Counting Scales

8 Pages

-

AD-4531B

2 Pages

-

AD-4530

2 Pages

-

LCM13 Series

2 Pages

-

Moisture Analyzer/M series

6 Pages

-

Data Acquisition System Omniace

16 Pages

-

Pipette Management Solutions

8 Pages

-

Laboratory Solutions by A&D

12 Pages

-

AD-1612 Comparator Buzzer

2 Pages

-

AD-1641 Air Flow Logger

4 Pages

-

Leak Tester/AD-1690

2 Pages

-

Weighing Data Logger/AD-1688

2 Pages

-

Washdown Scales/SC&SE Series

4 Pages

-

Users handbook for M series

30 Pages

-

Digital Indicator/AD-4532B

4 Pages

Archived catalogs

-

Press Release/FZ-i series

3 Pages