Catalog excerpts

TECHNOLOGY FOR HIGH PRECISION

Open the catalog to page 1

EVOLUTION OF A LONG TFIADITION

Open the catalog to page 3

made in italy Golden Compass award for industrial design D'ANDREA S.p.A., an Italian company, is a world leader in the production of high precision accessories for machine tools. D’Andrea was founded in 1951 by Marino D'Andrea, who started the business with the industry’s first facing and boring head. The D’Andrea brand is recognized worldwide for the quality and reliability of its product and are available through a dealer network in over 40 countries. D’Andrea Marino The Founder 1951 - The first Head for Boring and Facing Ermanno with his sons Amedeo and Marino and daughter Maria Pina. A...

Open the catalog to page 4

Lainate (Milan) D'Andrea S.p.A. represents the headquarters of the group, based in Lainate, a few kilometers from Milan. With over 7.000 sqm, D'Andrea boasts a modern, functioning and efficient plant where several machine tools are involved in the production of Tools and Heads. In particular, the grinding operations as well as the final test and assembly are here carried out.

Open the catalog to page 5

Castel Del Giudice (Isernia) D’Andrea Molise was founded in 2001 in Castel Del Giudice (Isernia), where Marino - the founder, was born. In this plant, most of the semi-finished products are made and, subsequently, finished, mounted and tested in the headquarters.

Open the catalog to page 6

CARBIDE BARS HIGH PRECISION ULTRA-TIGHT TOOLHOLDERS Ø 12 / 20 / 32 BORING-MILLING MACHINES MEDIUM AND LARGE SIZES TA-CENTER 2 TESTE CN 66-71 ARBORS TA-TRONIC 2 TESTE CN 72-73 ARBORS MACHINING CENTERS BACKWARD

Open the catalog to page 7

MILLING DRILLING BHT CROSS BARS BORING - TURNING BHT 250 BHT 500 CLAMPING POWER FORCE HIGH FORCE HIGH CLAMPING POWER PF SHELL MILL HOLDERS MILLING DRILLING FORCE HIGH CLAMPING POWER PRECISION COLLET CHUCK HOLDERS ER 16 / 25 / 32 EXTENDED ANGULAR HEADS PF SHELL MILL HOLDERS BORING-MILLING MACHINES MEDIUM AND LARGE SIZES GEARBOX DOUBLE SLIDE HIGH SPEED ( BALANCED ) FACING AND BORING HEADS AUTOMATIC FACING HEADS 74-75 START - STOP MACHINING CENTERS MILLING MACHINES MILLING-BORING MACHINE CONVENTIONAL MACHINES

Open the catalog to page 8

High-precision modular toolholders that are produced for boring, milling and drilling operations with extreme flexibility and rigidity. mo-cLuLhazcCcLnoLteCL The MHD’ coupling is the heart of the Modulhard’andrea tool system. Available in 8 sizes, it guarantees the interchangeability of all the elements of the system, which includes arbors, extensions, reductions and toolholder adapters.

Open the catalog to page 9

Extensions Reductions Vibration-damping Roughing Heads Testarossa -noi —owjr — dffMf TS 32/32 0 35.5 ~ 50 TRM 32 0 35.5 ~ 51.5 TRC 32 0 35.5 ~ 53.5 nr^ -□[’fin - aWM LBM CHUCKING TOOLS Power Chucks Collet chucks Shell mill holders

Open the catalog to page 10

DIN 69871 FC AD FACE CONTACT Cutting edge position B-shape arbors - on request

Open the catalog to page 11

Manufactured according to DIN 69871 and MAS 403 BT standards, made in case-hardened, tempered and grinded steel. BALANCING UP TO 8000 RPM. AD BT Cutting edge position B-shape arbors – on request AD FACE CONTACT Cutting edge position

Open the catalog to page 12

Manufactured according to DIN 69893,made in case-hardened, tempered and grinded steel. BALANCING UP TO 8000 RPM. HSK-A Cutting edge position pic.2 Supplied with coolant tube Cutting edge position AD Cutting edge position

Open the catalog to page 13

CARBIDE BARS

Open the catalog to page 14

EXTENSIONS - REDUCTIONS - VIBRATION-DAMPING For each MHD size there are extensions of different lengths that can be used to achieve the desired machining depths. The reductions allow the use of MHD components of a smaller size thereby optimising the composition of the tool according to the overall dimensions. Anti-vibration reductions for deep or heavy-duty machining.

Open the catalog to page 15

Simple and extremely rigid roughing heads, thanks to the serrated surfaces between the head body and the bit holders. The constant distance between the bit holder clamping screw and the cutting edge guarantees the stability of the system. ROUGHING HEADS 1. Body 2. Setting screws 3. Expanding pin 4. Coolant outlets Max BAR 40 5. Bit holders 6. Tools clamp screws

Open the catalog to page 17

USE TS for ROUGHING end SEMI-FINISHING operations Cutting edges might be adjusted on a presetting bench and TS heads can be used in three different configurations, with a single cutting edge (pic. 3) or misaligned ones (pic.2) half the feed. pic.1 with two SSCC bit holders aligned and on the same diameter for roughing operations with high feedrate. MHD’80 pic. 2 with one SSCC bit holder and one SMCC bit holder staggered and on a different diameter for roughing operations with high depth of cut. pic.3 with a single bit holder for roughing or semifinishing operations.

Open the catalog to page 18

TRM 16 RPM 12.000 TRM 20 RPM 12.000 TRM 25 RPM 10.000 TRM 32 RPM 10.000 TRM 40 RPM 8.000 TRM 50 RPM 8.000 TRM 63 RPM 6.000 TRM 80 RPM 5.000 TRM 125 RPM 4.000 TRM heads allow high precision machining and excellent surface finish in the IT6 tolerance class. The adjustment sensitivity of 1 micron on the radius is easily readable on the vernier scale and can also be performed in the machine spindle. 1. Body 2. Slide toolholder 3. Expanding radial pin 4. Micrometric vernier scale 5. Slide clamp screw 6. Coolant outlet Max BAR 40 7. Tools clamp screws 8. Oiler 9. Bit holder 10. Tool holder TRE 50...

Open the catalog to page 19

SFTP 25 SFTP 32 SFTP 50 P 25.63 PS 31.24 PS 32.24 CW 32 SFTP 25 SFTP 32 SFTP 50 P 25.63 PS 31.24 PS 32.24 CW 32 Working Range

Open the catalog to page 22

Vibration-damping Carbide

Open the catalog to page 23

Working Range

Open the catalog to page 25

THE TRC50 USES ALL THE TOOLS SUPPLIED WITH TRM50 (p.18-19) CCGT 0602.. CCGT 0602.. CCGT 0602.. CCGT 0602.. CCGT 09T3.. CCGT 09T3.. CCMT 1204.. TPGX 0902.. TPGX 0902.. TPGX 1103.. TPGX 1103.. TCMT 16T3..

Open the catalog to page 26

BACK-FACING CARTRIDGES SSQC-SFQC CALCULATION FORMULA FOR MINIMUM ENTERING Ø CARTRIDGE DIMENSIONS

Open the catalog to page 27

CHUCKING TOOLS PE COLLETS CHUCKING TOOLS AW WELDON WHISTLE NOTCH CHUCKING TOOLS PF DISC AND FACING CUTTER HOLDERS

Open the catalog to page 28

Offering of high-precision monolithic and modular tool holders to perform various different operations on machine-tools. The strong point of the PSC system is the ISO 26623 polygonal-conical connection which guarantees extreme rigidity even in the most demanding process. The system allows the use of the entire MHD’ line. PSC - TS complete line of t double-bit boring heads PSC - TRM complete line of micrometric heads for finishing from 0 2.5 mm to 0 220 mm. MONOforce line of high precision power milling chucks ideal for machining where precision and high clamping forces for the cutting tool...

Open the catalog to page 29All D'Andrea S.p.A. catalogs and technical brochures

-

TOOLS HEADS 2023

82 Pages

-

ONE STEP AHEAD

2 Pages

-

GENERAL CATALOGUE

138 Pages

-

U-TRANSFER

2 Pages

-

DRACO

4 Pages

-

U-TRONIC S+R

2 Pages

-

CATALOG 2018

306 Pages

-

Boring and Turning System

2 Pages

-

D'ANDREA FAMILY

4 Pages

Archived catalogs

-

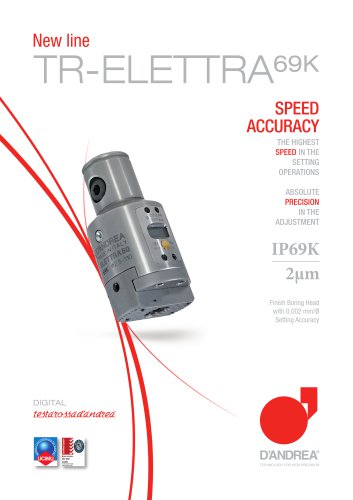

TR-ELETTRA 69K

2 Pages

-

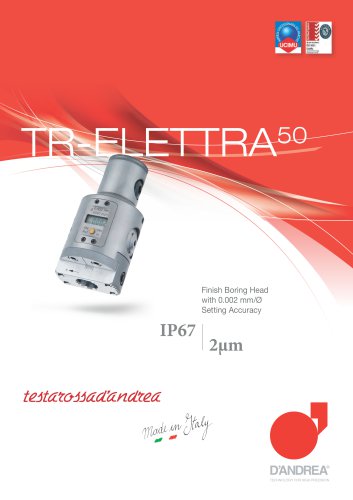

TR-Elettra 50

2 Pages

-

NEW 2015 CATALOG

258 Pages

-

NEW CATALOGUES 2013

234 Pages

-

CATALOGUE D'Andrea HEADS

78 Pages

-

CATALOGUE D'Andrea TOOLS

278 Pages